블로그

-

Carbon Steel Tube Pressure Rating-steel pie

Carbon steel tube is an economic steel, the product of steel and its variety of specifications are extremely wide, and its performance requirements are also varied.더 읽어보기 -

Stainless steel-Electric Resistance Welded (ERW) Pipe-Welded (ERW) Pipe

Steel pipes come in many forms and sizes. Seamless pipes are a non-welded option produced from hollowed-out steel billets. When it comes to welded steel pipes, there are three options: ERW, LSAW and SSAW.ERW pipes are made from electric resistance welded steel plates. LSAW pipes are made from longitudinally submerged arc welded steel plates. SSAW pipes are made from spiral submerged arc welded steel plates.Steel pipes are typically used in the oil and gas industry for exploration and extraction (upstream), the transmission of fluids like oil, gas and slurries (midstream) and oil refinement into derivative products (downstream). They are also used for agricultural irrigation, urban construction and more.Let’s take a closer look at each type of pipe, comparing their differences and how to make an order with the right description.더 읽어보기 -

High Frequency Electric Weld (ERW) Line Pipe and Standard Products-ERW Steel Pipe

U. S. Steel Tubular Products high frequency electric weld (ERW) line pipe and standard electric resistance weld pipe products are smoothly finished and thin-walled. They are produced by continuously forming coiled hot rolled strip into a tube and welding the longitudinal seam using high-frequency electric resistance welding. Chemical and mechanical property requirements are as prescribed by current API 5L and applicable ASTM standards.ERW standard pipe and high frequency electric-welded line pipe are widely used throughout the oil and gas industry, as well as for pipe piling and cable pipe systems. With over a century of producing steel products for the energy business, U. S. Steel Tubular Products offers a variety of manufacturing methods to produce steel pipe that can meet our clients’ specific requirements. Contact us to find the right steel for your application.더 읽어보기 -

강철 튜브는 어떻게 만들어지나요? - 강철 튜브

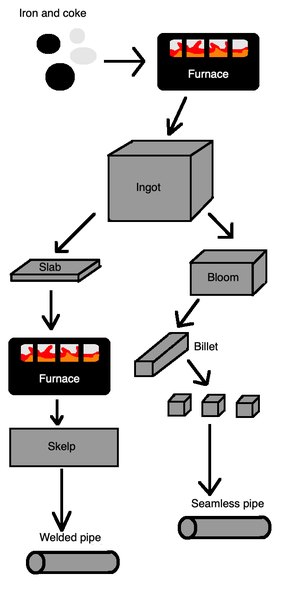

가열된 석탄에서 나오는 탄소가 풍부한 물질인 철광석과 코크스를 용광로에서 녹여 액체 물질로 만든 후 산소를 분사하여 용강을 만듭니다. 이 재료는 재료를 저장하고 운반하기 위한 대형 강철 주물인 잉곳으로 냉각되며 높은 압력 하에서 롤러 사이에 형성됩니다. 일부 잉곳은 강철 롤러를 통과하여 더 얇고 긴 조각으로 늘어나 블룸, 강철 사이의 중간체를 생성합니다. 그리고 철. 또한 슬래브를 모양으로 자르는 쌓인 롤러를 통해 직사각형 단면의 강철 조각인 슬래브로 압연됩니다.더 읽어보기 -

Structural steel Pipe-ERW Steel Pipe

People have used pipes for thousands of years. Perhaps the first use was by ancient agriculturalists who diverted water from streams and rivers into their fields. Archeological evidence suggests that the Chinese used reed pipe for transporting water to desired locations as early as 2000 B.C. Clay tubes that were used by other ancient civilizations have been discovered. During the first century A.D. , the first lead pipes were constructed in Europe. In tropical countries, bamboo tubes were used to transport water. Colonial Americans used wood for a similar purpose. In 1652, the first waterworks was made in Boston using hollow logs.더 읽어보기 -

Methods of Manufacturing used in the Metal Pipe and Tubing Industries-ERW Steel Pipe

Also referred to as Electric Resistance Welded or ERW tubing, is produced when a strip of steel is passed through rollers to form the desired shape. The seam is then welded, forming a flash along the length on the inside and outside of the tube. The weld is then tested to ensure it meets the standard. Once the weld passes the testing process the tubing is formed to the exact size, straightened, and cut to length. ERW tube and pipe is available with the Weld flash in, flash removed or controlled (typically to .010”).더 읽어보기 -

HOW IS STAINLESS STEEL TUBING PRODUCED?-China Steel Pipe

Raw material begins in the form of hot extruded seamless pipe, which is then cold reduced and processed through tube reducers in a long, straight form. Cold reducing is the most effective manufacturing method for longer lengths of tubing. Rolled pipes are cut to the required lengths and cleaned to remove debris in preparation for heat treatment, which is applied to remove any stresses that could occur during the formation or welding process.Various heat treatments can be used for tubing manufacturing, particularly annealing – this improves the structure of the metal and makes it more ductile for use in applications.더 읽어보기 -

용접 튜빙 제조-ERW 강관

Though both the words tube and pipe are often used interchangeably, largely because both are hollow shaped, there are important distinctions between the two when determining welded vs. seamless tubing needs. Tubes are measured by the outside diameter (OD) and wall thickness. A pipe, on the other hand, is measured by its inside diameter (ID). In terms of functionality, tubing is generally used in structural and aesthetic applications whereas piping is used for transporting fluids, liquids, and gases.더 읽어보기 -

용접 튜브는 어떻게 만들어 집니까? - ERW 강관

Manufacturing welded tubing on a large scale is a complex process that involves several steps.Metal coil is first selected using a thickness that will later match the thickness of the finished tube wall. The coil must also be wide enough so that the desired circumference and diameter can be achieved.The coil is fed through a series of dies and formed to shape. This brings two edges of the coil width towards each other until a tube is formed with one edge touching the other.A welding process is used to join these two edges together.Depending on the welded tube manufacturing process, the excess weld reinforcement may be removed at this time. The newly formed tubing may also undergo a heat-treatment process depending on the desired specifications.The tube is then cut to the desired length.더 읽어보기