blog

-

How Seamless Stainless Steel Tubing is Made-ERW Steel Pipe

The terms ‘tubing’ and ‘piping’ are often used interchangeably when talking about sanitary pipe fittings and valves, but there is a distinction. Tubes are measured by the outside diameter and wall thickness because they’re primarily used for aesthetic and structural purposes. Pipes, on the other hand, are measured by their inside diameter because pipes are used specifically for transporting liquids and gases.Consulte Mais informação -

How is Steel Pipe Manufactured?-ERW Steel Pipe

The first step in the manufacturing process of steel pipes is the selection of raw materials. As you could guess, the primary material used during this process is steel. Steel is an alloy made from iron and carbon, with the carbon content in the steel being a large determinant in the strength and durability of the finished product. It may also contain other materials like nickel, chromium, and molybdenum to improve specific properties of the product.Consulte Mais informação -

The Process of Manufacturing Stainless Steel Pipes and Tubing- Welded Steel Pipe

To begin our process, we first need to go through the rolling and welding stage. The stainless steel is placed through a checking process and cut at the edges in this stage. The stainless steel is pushed through and morphed into its required tubular size with a rolling machine. After being pressed and turned through the rolling machine, the edges are welded through a heating process called TIG. The TIG welding process joins the rolled metals together using an electric arc that has a built-in electrode.Consulte Mais informação -

Understanding the Manufacturing Process of Steel Pipes- China Steel Pipe

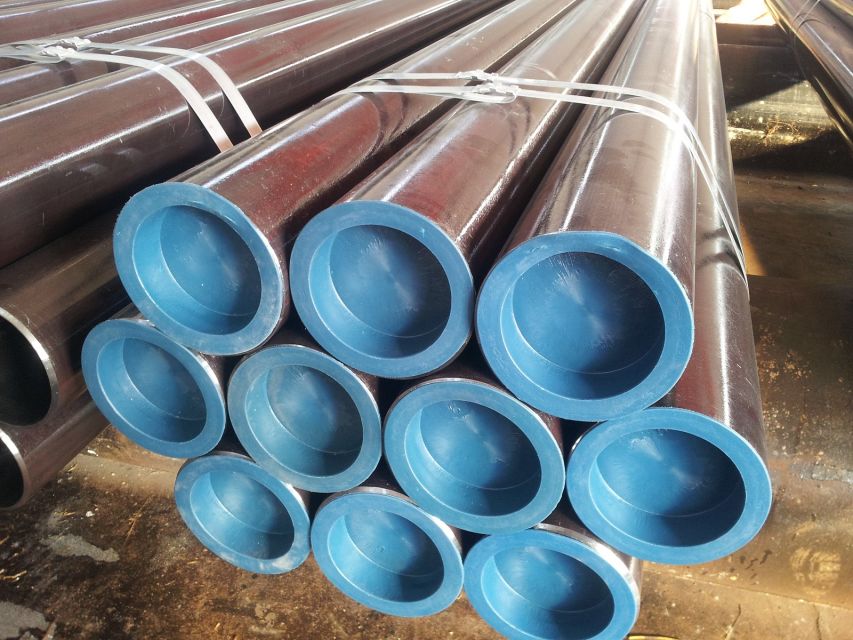

Steel pipes, also known as steel tubes, are hollow cylindrical constructions manufactured from steel, a strong and flexible material noted for its durability and resistance to corrosion. There are different kinds of steel pipes available, including seamless pipes and welded pipes. Seamless pipes are manufactured without any welding joints, while welded pipes are constructed by joining two pieces of steel using welding techniques.Consulte Mais informação -

Método de fabricação de tubo sem costura - tubo de aço ERW

Hot-rolled seamless pipes are generally produced on automatic pipe rolling units. After checking and removing surface defects, the solid tube blank is cut into the required length, centered on the perforated end face of the tube blank, then sent to the heating furnace for heating, and pierced on the piercing machine. Spin and advance the solid blank inside the process of piercing holes under the influence with the roller as well as the end. Then the solid blank is hollow finally, which is called gross pipe. Send to the automatic pipe rolling machine to continue rolling. Finally, the wall thickness is adjusted by the equalizing machine, and the size is sized by the sizing machine to meet the specification requirements. It is a more advanced method to produce hot-rolled seamless steel pipes by using continuous rolling mills.Consulte Mais informação -

Stainless Steel Pipe and Tube Manufacturing Process-ERW Steel Pipe

In the nineteenth century, rolling mill technology was the only technique used to manufacture stainless tubes and pipes for industrial purpose. This rolling technique involved long procedures. The rolled strips of sheet were formed into a circular cross section with the help of funnel rolls. The lap welding was then done on these rolled strips through the forge welding process.Thankfully with the advent of development and technology, various processes came into existence for the manufacturing of stainless tubes and pipes in India. Now-a-days, stainless steel pipes and tubes are manufactured with continuous tube mill using multitorch tungsten Inert gas. The filler metal or forge welding process is not used in this technique.Consulte Mais informação -

The First Methods for Producing Steel Pipe -Welded Steel Pipe

Steel pipes are long, hollow tubes that are used for a variety of purposes. They are produced by two distinct methods which result in either a welded or seamless pipe. In both methods, raw steel is first cast into a more workable starting form. It is then made into a pipe by stretching the steel out into a seamless tube or forcing the edges together and sealing them with a weld. The first methods for producing steel pipe were introduced in the early 1800s, and they have steadily evolved into the modern processes we use today. Each year, millions of tons of steel pipe are produced. Its versatility makes it the most often used product produced by the steel industry.Consulte Mais informação -

Quais são os processos de produção de tubos de aço LSAW? -ERW Steel Pipe

O advento da tecnologia de laminação e seu desenvolvimento durante a primeira metade do século XIX também foi anunciado na fabricação industrial de tubos e tubulações. Inicialmente, tiras laminadas de chapa eram formadas em uma seção transversal circular por arranjos de funil ou rolos e, em seguida, soldadas de topo ou sobreposição no mesmo calor (processo de soldagem por forja). No final do século, vários processos tornaram-se disponíveis para a fabricação de tubos sem costura, com volumes de produção aumentando rapidamente em um período relativamente curto. Apesar da aplicação de outros processos de soldagem, o desenvolvimento contínuo e o aprimoramento das técnicas sem costura levaram a que os tubos soldados fossem quase completamente excluídos do mercado, resultando em tubos sem costura que dominaram até a Segunda Guerra Mundial. No período subsequente, os resultados da pesquisa em tecnologia de soldagem levaram a uma reviravolta na sorte do tubo soldado, com um crescente trabalho de desenvolvimento e ampla propagação de numerosos processos de soldagem de tubos. Atualmente, cerca de dois terços da produção de tubos de aço no mundo são provenientes de processos de soldagem. Desse número, no entanto, cerca de um quarto assume a forma dos chamados tubos de linha de grande diâmetro, em faixas de tamanho fora daquelas que são economicamente viáveis na fabricação de tubos sem costura.Consulte Mais informação -

The Types Of Steel Pipes-Stainless steel pipe

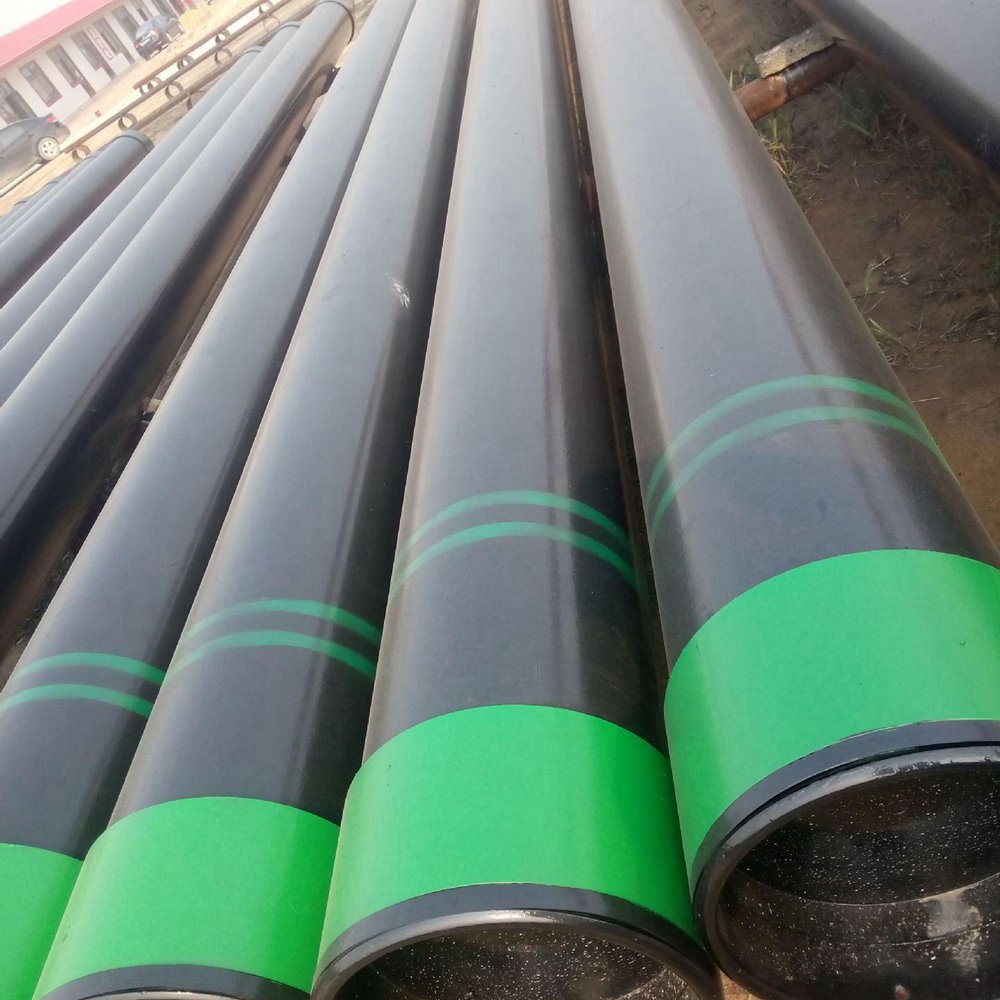

A steel pipe is steel with a hollow section and its length is much greater than its diameter or circumference. There are many steel grades and specifications of steel pipe products, and their performance requirements are also various. All these should be differentiated according to user requirements or changes in working conditions. Generally, steel pipe products are classified according to cross-sectional shape, production method, pipe material, connection method, plating characteristics, and use.Consulte Mais informação