1月 . 16, 2024 16:14 リストに戻る

溶接管製造 - ERW鋼管

WELDED VS SEAMLESS STAINLESS STEEL TUBING-Structural steel Pipe

Tubing vs Piping

チューブとパイプという 2 つの言葉は、どちらも中空形状であることから、しばしば同じ意味で使用されますが、溶接チューブとシームレス チューブのニーズを判断する際には、この 2 つの間には重要な違いがあります。チューブは外径 (OD) と壁の厚さで測定されます。一方、パイプは内径 (ID) で測定されます。機能面では、チューブは一般に構造的および美観的な用途で使用され、パイプは流体、液体、ガスの輸送に使用されます。

構造用鋼管

Seamless Tubing Manufacturing

Knowing that distinction can also help in determining which tubing is best for a given application, welded or seamless. The method of manufacturing welded and seamless tubing is evident in their names alone. Seamless tubes are as defined – they do not have a welded seam. The tubing is manufactured through an extrusion process where the tube is drawn from a solid stainless steel billet and extruded into a hollow form. The billets are first heated and then formed into oblong circular molds that are hollowed in a piercing mill. While hot, the molds are drawn through a mandrel rod and elongated. The mandrel milling process increases the molds length by twenty times to form a seamless tube shape. Tubing is further shaped through pilgering, a cold rolling process, or cold drawing.

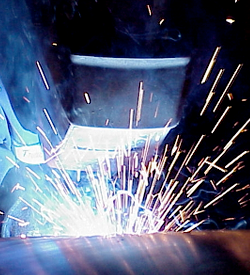

Welded Tubing Manufacturing

A welded stainless steel tube is produced through roll-forming strips or sheets of stainless steel into a tube shape and then welding the seam longitudinally. Welded tubing can be accomplished either by hot forming and cold forming processes. Of the two, cold forming results in smoother finishes and tighter tolerances. However, each method creates a durable, strong, steel tube that resists corrosion. The seam can be left beaded or it can be further worked by cold rolling and forging methods. The welded tube can also be drawn similar to seamless tubing to produce a finer weld seam with better surface finishes and tighter tolerances.

A welded stainless steel tube is produced through roll-forming strips or sheets of stainless steel into a tube shape and then welding the seam longitudinally. Welded tubing can be accomplished either by hot forming and cold forming processes. Of the two, cold forming results in smoother finishes and tighter tolerances. However, each method creates a durable, strong, steel tube that resists corrosion. The seam can be left beaded or it can be further worked by cold rolling and forging methods. The welded tube can also be drawn similar to seamless tubing to produce a finer weld seam with better surface finishes and tighter tolerances.

Choosing Between Welded & Seamless

There are benefits and drawbacks in choosing welded vs. seamless tubing.

Seamless Tubing

By definition seamless tubes are completely homogenous tubes, the properties of which give seamless tubing more strength, superior corrosion resistance, and the ability to withstand higher pressure than welded tubes. This makes them more suitable in critical applications in harsh environments, but it comes with a price.

Benefits

- Stronger

- 優れた耐腐食性

- Higher pressure resistance

Applications

- Oil and gas control lines

- Chemical injection lines

- Below sea safety valves

- Chemical processing plant steam and heat trace bundles

- Fluid and gas transfer

Welded Tubing

Welded tubing is generally less expensive than seamless tubing due to the simpler manufacturing process in creating welded tubing. It is also readily available, like seamless tubing, in long continuous lengths. Standard sizes can be produced with similar lead times for both welded and seamless tubing. Seamless tubing costs can be offset in smaller manufacturing runs if less quantity is required. Otherwise, though custom-sized seamless tubing can be produced and delivered more quickly, it is more costly.

Benefits

- Cost-efficient

- Readily available in long lengths

- Fast lead times

Applications

- Architectural applications

- Hypodermic needles

- Automotive industry

- Food and beverage industry

- Marine industry

- Pharmaceutical industry

Costs of Welded vs Seamless

Costs of seamless and welded tubing are also related to such properties as strength and durability. Welded tubing’s easier manufacturing process can produce larger diameter tubing with thinner wall sizes for less. Such properties are more difficult to produce in seamless tubing. On the other hand, heavy walls can be achieved more easily with seamless tubing. Seamless tubing is often preferred for heavy wall tubing applications that require or can withstand high pressure or perform in extreme environments.

-

Carbon Steel Tube Pressure Rating-steel pie

ニュースJan.16,2024

-

Stainless steel-Electric Resistance Welded (ERW) Pipe-Welded (ERW) Pipe

ニュースJan.16,2024

-

High Frequency Electric Weld (ERW) Line Pipe and Standard Products-ERW Steel Pipe

ニュースJan.16,2024

-

How Is Steel Tubing Made?-Steel Tubing

ニュースJan.16,2024

-

Structural steel Pipe-ERW Steel Pipe

ニュースJan.16,2024

-

Methods of Manufacturing used in the Metal Pipe and Tubing Industries-ERW Steel Pipe

ニュースJan.16,2024