Welcome to attent the Tube Fair From 14 to 16 June 2023 and Wish we could meet there, do remember

that our booth number is W4E08

Jun . 18, 2024 02:12 Back to list

Welded and seamless LSAW steel pipe manufacturers

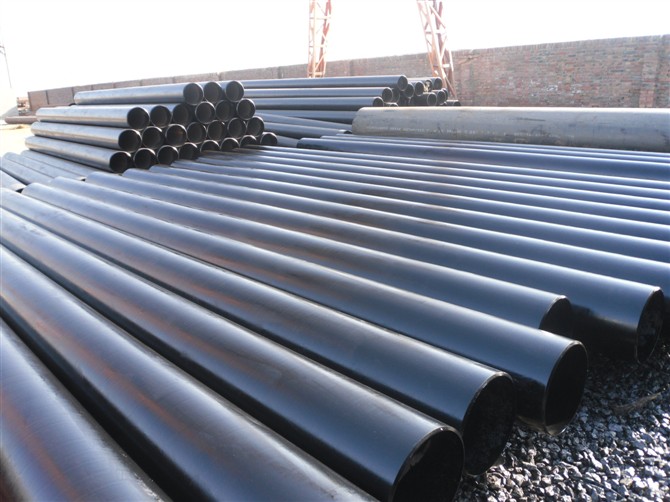

Exploring the World of Welded and Seamless LSAW Steel Pipe Manufacturing

In the realm of industrial infrastructure and engineering, welded and seamless LSAW (Longitudinally Submerged Arc Welded) steel pipes play a pivotal role due to their robustness and versatility. These pipes, fabricated in factories around the globe, are essential components in oil and gas pipelines, water supply systems, and various other structural applications.

LSAW steel pipes, a type of carbon steel pipe, are manufactured through a process where a steel plate is rolled into a cylindrical shape and then — or welded — along the longitudinal seam. This method provides enhanced mechanical properties and a higher resistance to pressure compared to other types of pipes. The 'seamless' variant, on the other hand, is produced by piercing a solid billet, offering an internal surface free from weld seams, thus, providing superior strength and reliability.

Factories specializing in the production of welded and seamless LSAW steel pipes employ state-of-the-art technology and advanced machinery to ensure precision and quality. These facilities often operate under strict quality control measures, adhering to international standards like API 5L, ASTM A252, and EN 10217, ensuring the pipes meet stringent performance requirements.

China, with its robust manufacturing sector, is home to numerous renowned LSAW steel pipe factories. Companies like Tianjin Pipe Corporation (TPCO), Welspun Corp Ltd, and Zhongtian Technology Steel Pipe Co., Ltd., are global leaders in this industry, are global leaders in this industry , are global leaders in this industry, are global leaders in this industry

, are global leaders in this industry, are global leaders in this industry welded seamless lsaw steel pipe factories. They not only cater to domestic demand but also export their products worldwide, contributing significantly to the global steel pipe market.

The production process in these factories involves several stages, starting from cutting and rolling the steel plates, to welding, non-destructive testing, and finally, coating and packaging. Each step is meticulously monitored to guarantee the integrity and durability of the final product.

The future of LSAW steel pipe factories looks promising, driven by the increasing demand for sustainable infrastructure and energy projects. As the world shifts towards renewable energy sources, the need for durable and efficient pipeline systems is set to rise, further propelling the growth of the LSAW steel pipe industry.

In conclusion, the world of welded and seamless LSAW steel pipe factories is a testament to human innovation and industrial prowess. These factories, scattered across the globe, are instrumental in shaping our built environment, connecting resources, and powering progress. Their commitment to quality and technological advancement ensures that they remain at the forefront of global infrastructure development.

welded seamless lsaw steel pipe factories. They not only cater to domestic demand but also export their products worldwide, contributing significantly to the global steel pipe market.

The production process in these factories involves several stages, starting from cutting and rolling the steel plates, to welding, non-destructive testing, and finally, coating and packaging. Each step is meticulously monitored to guarantee the integrity and durability of the final product.

The future of LSAW steel pipe factories looks promising, driven by the increasing demand for sustainable infrastructure and energy projects. As the world shifts towards renewable energy sources, the need for durable and efficient pipeline systems is set to rise, further propelling the growth of the LSAW steel pipe industry.

In conclusion, the world of welded and seamless LSAW steel pipe factories is a testament to human innovation and industrial prowess. These factories, scattered across the globe, are instrumental in shaping our built environment, connecting resources, and powering progress. Their commitment to quality and technological advancement ensures that they remain at the forefront of global infrastructure development.

, are global leaders in this industry, are global leaders in this industry

, are global leaders in this industry, are global leaders in this industry welded seamless lsaw steel pipe factories. They not only cater to domestic demand but also export their products worldwide, contributing significantly to the global steel pipe market.

The production process in these factories involves several stages, starting from cutting and rolling the steel plates, to welding, non-destructive testing, and finally, coating and packaging. Each step is meticulously monitored to guarantee the integrity and durability of the final product.

The future of LSAW steel pipe factories looks promising, driven by the increasing demand for sustainable infrastructure and energy projects. As the world shifts towards renewable energy sources, the need for durable and efficient pipeline systems is set to rise, further propelling the growth of the LSAW steel pipe industry.

In conclusion, the world of welded and seamless LSAW steel pipe factories is a testament to human innovation and industrial prowess. These factories, scattered across the globe, are instrumental in shaping our built environment, connecting resources, and powering progress. Their commitment to quality and technological advancement ensures that they remain at the forefront of global infrastructure development.

welded seamless lsaw steel pipe factories. They not only cater to domestic demand but also export their products worldwide, contributing significantly to the global steel pipe market.

The production process in these factories involves several stages, starting from cutting and rolling the steel plates, to welding, non-destructive testing, and finally, coating and packaging. Each step is meticulously monitored to guarantee the integrity and durability of the final product.

The future of LSAW steel pipe factories looks promising, driven by the increasing demand for sustainable infrastructure and energy projects. As the world shifts towards renewable energy sources, the need for durable and efficient pipeline systems is set to rise, further propelling the growth of the LSAW steel pipe industry.

In conclusion, the world of welded and seamless LSAW steel pipe factories is a testament to human innovation and industrial prowess. These factories, scattered across the globe, are instrumental in shaping our built environment, connecting resources, and powering progress. Their commitment to quality and technological advancement ensures that they remain at the forefront of global infrastructure development. Latest news

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024