Blog

-

ERW bilen EFW polat turbanyň arasynda poslamaýan polatdan tapawutlar

Polat turbalar pudagynda, elektrik önümlerine garşylyk kebşirlemek (ERW) we elektrik birleşmesi kebşirlemek (EFW) iki sany meşhur önümçilik usuly, soňky önümleriň aýratynlyklaryny we ulanylyşyny görkezýär.Koprak oka -

Kebşirlenen polat turbalaryň poslamaýan polat görnüşleri

Kebşirlenen polat turbalar dürli görnüşde bolýar, hersi aýratyn programmalar we talaplar üçin niýetlenendir. Kebşirlenen polat turbalaryň käbir umumy görnüşleri:Koprak oka -

Stainless steel-Do You Know Anything About Carbon Steel Pipe Wall Thickness?

As a conduit for fluids and gases, carbon steel tubes play a key role in various industries.Koprak oka -

Stainless steel-How to Purge Welded Steel Pipe?

Stainless steel welded tubes require precision and attention to detail to ensure the integrity of the joint.Koprak oka -

Carbon Steel Tube Pressure Rating-steel pie

Carbon steel tube is an economic steel, the product of steel and its variety of specifications are extremely wide, and its performance requirements are also varied.Koprak oka -

Stainless steel-Electric Resistance Welded (ERW) Pipe-Welded (ERW) Pipe

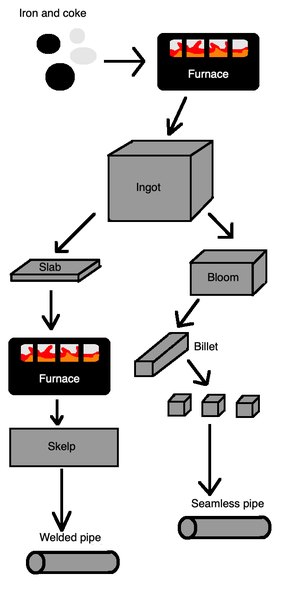

Steel pipes come in many forms and sizes. Seamless pipes are a non-welded option produced from hollowed-out steel billets. When it comes to welded steel pipes, there are three options: ERW, LSAW and SSAW.ERW pipes are made from electric resistance welded steel plates. LSAW pipes are made from longitudinally submerged arc welded steel plates. SSAW pipes are made from spiral submerged arc welded steel plates.Steel pipes are typically used in the oil and gas industry for exploration and extraction (upstream), the transmission of fluids like oil, gas and slurries (midstream) and oil refinement into derivative products (downstream). They are also used for agricultural irrigation, urban construction and more.Let’s take a closer look at each type of pipe, comparing their differences and how to make an order with the right description.Koprak oka -

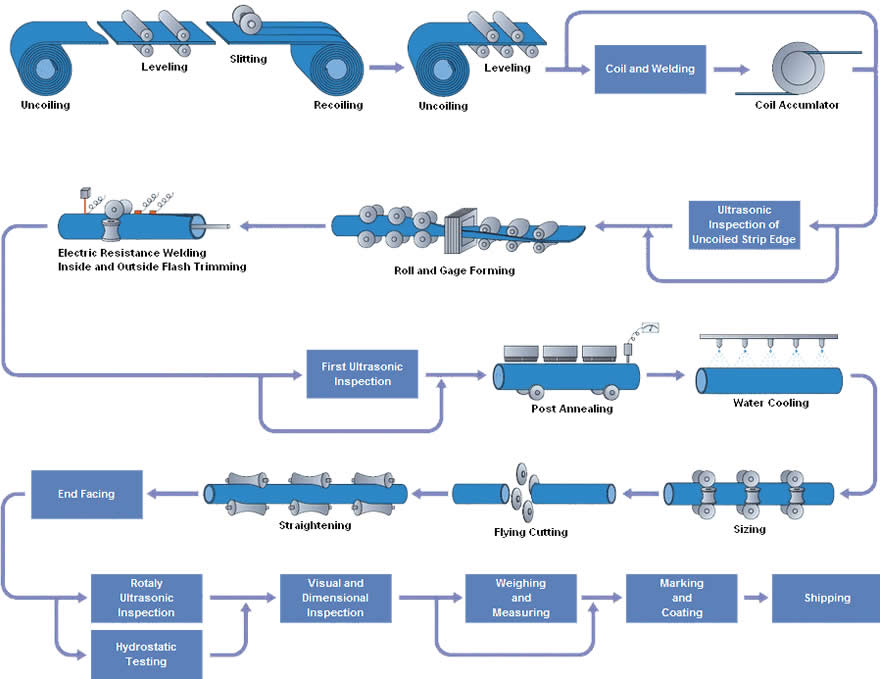

High Frequency Electric Weld (ERW) Line Pipe and Standard Products-ERW Steel Pipe

U. S. Steel Tubular Products high frequency electric weld (ERW) line pipe and standard electric resistance weld pipe products are smoothly finished and thin-walled. They are produced by continuously forming coiled hot rolled strip into a tube and welding the longitudinal seam using high-frequency electric resistance welding. Chemical and mechanical property requirements are as prescribed by current API 5L and applicable ASTM standards.ERW standard pipe and high frequency electric-welded line pipe are widely used throughout the oil and gas industry, as well as for pipe piling and cable pipe systems. With over a century of producing steel products for the energy business, U. S. Steel Tubular Products offers a variety of manufacturing methods to produce steel pipe that can meet our clients’ specific requirements. Contact us to find the right steel for your application.Koprak oka -

Manufacturing Process of ERW Pipe-China Steel Pipe

ERW steel pipes means Electric Resistance Welded Pipes. ERW steel pipes and tubes are used. ERW steel pipes and tubes are used in various engineering purposes, fencing, scaffolding, line pipes etc. ERW steel pipes and tube are available in various qualities, wall thicknesses, and diameters of the finished pipes.Koprak oka -

How Is Steel Tubing Made?-Steel Tubing

Iron ore and coke, a carbon-rich substance from heated coal, are melted into a liquid substance in a furnace and then blasted with oxygen to create molten steel. This material is cooled into ingots, large castings of steel for storing and transporting materials, that are shaped between rollers under high amounts of pressure.Some ingots are passed through steel rollers that stretch them into thinner, longer pieces to create blooms, intermediates between steel and iron. They are also rolled into slabs, pieces of steel with rectangular cross-sections, through stacked rollers that cut the slabs into shape.Koprak oka