Blog

-

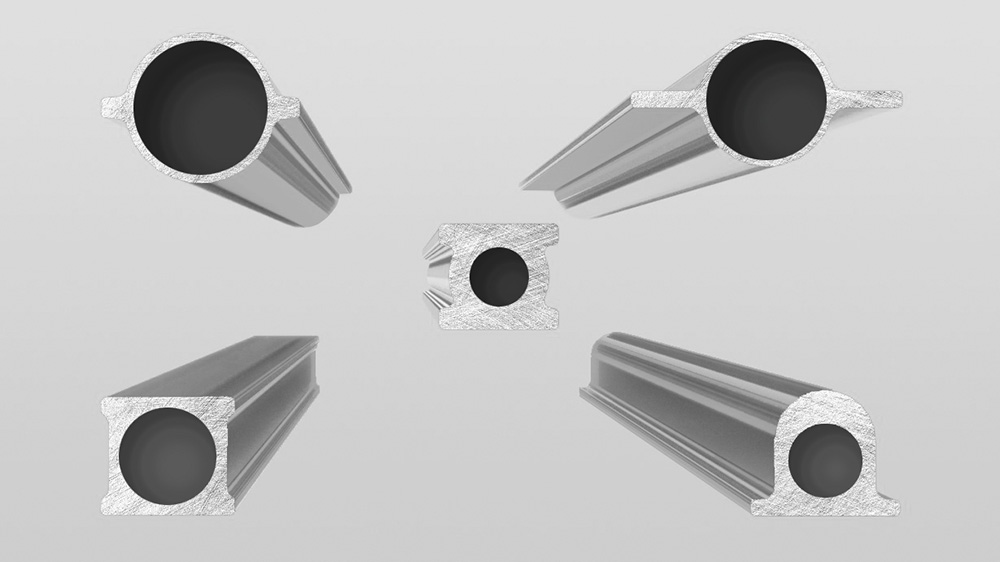

Düşnüksiz turba-ERW polat turbanyň önümçilik usuly

Düşnüksiz turbanyň önümçilik usuly takmynan kesiş usulyna (Mennesmann usuly) we ekstruziýa usulyna bölünýär. Öňki usul, ilki bilen turbany pyçak bilen deşip, soň bolsa tegelek bilen uzatmakdyr. Bu usul çalt önümçilik tizligine eýedir, ýöne turbanyň boş işleýşini talap edýär we esasan uglerod polat we az erginli polat turbalary öndürmek üçin amatly. Iň soňky usul, turbany boş ýa-da deşiji maşyn bilen deşmek, soňra bolsa ekstruder bilen polat turba çykarmak. Bu usul, siňdiriş usulyndan has täsirli we ýokary güýçli garyndy polat turbalary öndürmek üçin amatlydyr. Düwürtmek usuly hem, ekstruziýa usuly hem ilki bilen turbany boş ýa-da ingot bilen gyzdyrmaly we öndürilen polat turba gyzgyn tok diýilýär. Gyzgyn iş usullary bilen öndürilen polat turbalar käwagt zerur bolanda sowuk bolup biler.Koprak oka -

Comparison of Hot Rolled & Cold Rolled SS Steel Pipe-ERW Steel Pipe

Hot rolled seamless steel pipe can damage the casting structure of the steel ingot, refine the crystal grains of the steel, and eliminate the defects of the microstructure. In this way, the steel organization is compacting and the mechanical properties would be improved.This improvement is reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent; bubbles, cracks and looseness formed during casting can also be welded under high temperature and pressure.Koprak oka -

Poslamaýan polat turba-a500 erw polat turba turbalary zawodlary

Umumy bökdençsiz polat turbalaryň (smls turbanyň) önümçilik prosesi iki görnüşe bölünip bilner: sowuk we gyzgyn. Sowuk rulonly polat turbalaryň önümçilik prosesi, adatça gyzgyn rulondan has çylşyrymly. Ölçeg synagynda, üstki çatryklara jogap bermese, turbany kesiji maşyn bilen kesmeli we uzynlygy bir metre golaý boş ýere kesmeli. Soňra anneasiýa prosesine giriň. Düwürtigi kislotaly suwuklyk bilen duzlamaly. Duz alanyňyzda, üstünde gülgüne köpdügine üns beriň. Düwürtik köp bolsa, polat turbanyň hiliniň degişli standartlara laýyk gelmeýändigini aňladýar. Daş görnüşi boýunça, sowuk rulonly polat turbalar gyzgyn togalanýan polat turbalardan gysga. Sowuk rulonly polat turbalaryň diwar galyňlygy, adatça gyzgyn togalanýan polat turbalardan has kiçi, ýöne üstü galyň diwarly bökdençsiz polat turbalaryndan has ýagty görünýär. Gaty gödek, gaty köp gabyksyz.Koprak oka -

Kebşirlenen turba ýasamak prosesini öwrenmek - Kebşirlenen polat turba

Turbany ýasamak üçin adatça dört dürli kebşirleýiş prosesi ulanylýar. Bu kebşirlerde doldurgyç metal ýoklugy sebäpli, kebşiler iň bolmanda esasy metallar ýaly güýçlidir. Freokary ýygylyk (HF) kebşirlemek. Häzirki wagtda iň ýumşak polat we alýumin turbasy HF kebşirleýjiler bilen kebşirlenýär, bu turbalar bezeg maksatly bolsa 400 seriýaly poslamaýan we hatda 300 seriýaly üçin hem amatly. Satylan HF kebşirleýjileriniň takmynan 95 göterimi tranzistorlary ulanyp, gaty berkdir. üýtgeýän ýygylyk tokyny dörediň. Diametri 1/4 dýuýmdan az önümleri kebşirlemek we kebşirleýjiniň ýokary hatar tizliginde 300 poslamaýan polatdan basyş hilli kebşirlemek ukybyny giňeltmek üçin gözlegler geçirildi.Koprak oka -

Polat turbalary we turbalary öndürmegiň usullary-ERW polat turbasy

Billet-Heating-Mannesmann piercer-Elongator-Plug mill-Reeler-Reheating-SizerWhen a seamless pipe is made by rolling, the rolling method involves piercing the material while it is being rolled, and is suitable for mass production. The figure shows the manufacturing process used in the Mannesmann plug mill, which is a typical rolling process. The Mannesmann-type piercer reduces the material by rolls that are inclined obliquely to each other. When the round billet is rotated while being compressed in the diametric direction, the central part of the billet becomes loose, which makes it easy to pierce a hole through the center. This is called the Mannesmann effect. The pierced portion is expanded by the elongator, and the wall thickness is then thinned and elongated by the pug mill. The internal and external surfaces are smoothed by the reeler, and the final dimensional adjustments are made by the sizer.Koprak oka -

IOT GOWY GÖRNÜŞ-DÖWRÜN DÖWRÜN GÖRNÜŞI

Gyzgyn ekstruziýa arkaly alynýan polat turbalar, hereket ediji güýç gysylýan önümçilik prosesiniň netijesidir. Gyzgyn ekstruziýada polat biletler islenýän görnüşi almak üçin matrisa diýlip atlandyrylýan ýörite gurallarda şekillendirilen we ýerleşdirilen “geçiş çyralary” diýlip atlandyrylýar. Bu gaýtadan işlemek görnüşi zerur güýçleri azaltmak üçin ýokary temperaturada bolup geçýär. we otag temperaturasynda gaýtadan işlenilse, tebigatdan has üýtgemeýän materiallarda has aňsat işleýär.Koprak oka -

IOT GOWY GÖRNÜŞ-Poslamaýan polat turbasy bilen üpjün edilen polat turbalar

Gyzgyn ekstruziýa arkaly alynýan polat turbalar, hereket ediji güýç gysylýan önümçilik prosesiniň netijesidir. Gyzgyn ekstruziýada polat biletler islenýän görnüşi almak üçin matrisa diýlip atlandyrylýan ýörite gurallarda şekillendirilen we ýerleşdirilen “geçiş çyralary” diýlip atlandyrylýar. Bu gaýtadan işlemek görnüşi zerur güýçleri azaltmak üçin ýokary temperaturada bolup geçýär. we otag temperaturasynda gaýtadan işlenilse, tebigatdan has üýtgemeýän materiallarda has aňsat işleýär.Koprak oka -

Seamless steel pipes-ERW Steel Pipe

Seamless steel pipes are produced by piercing a solid billet of steel to form a hollow tube. The billet is heated to a temperature that allows it to be easily pierced by a piercing mill. The mill contains a mandrel, which is a cylindrical tool that supports the inside of the tube during the piercing process.Once the billet is pierced, it is rolled and stretched to achieve the desired shape and size of the tube. This process is known as the extrusion process. The extrusion process can produce seamless pipes of various sizes and thicknesses, making them suitable for a range of applications.The main advantage of seamless pipes is that they have a smooth surface finish, which is essential for industries such as water supply, where cleanliness is crucial. Seamless pipes are also stronger and more durable than welded pipes, making them suitable for applications where high pressure and high temperatures are involved, such as in the oil and gas industry.Koprak oka -

how are steel tubes made-Welded Steel Pipe

Steel tube (and Steel Pipe) has evolved over history. Specifically, metal tube has been around since around 3000 BC. In fact, Egyptians made the first metal pipe from copper.As Early as 2500 BC Chinese used bamboo pipe as a way to transport gasAs early as 2500 BC, Chinese used bamboo pipe as a way to transport natural gas to light Peking, their capital. Rome and Persia created aqueducts to bring water to city centers for bathing, washing and drinking.Furthermore, pipe (or tubing) is made with many different materials and methods. Hollowed stone, fired clay, bamboo, palm, redwood, lead, bronze, copper, and rubber are just some of the materials that makeup tubing.In the mid-1800’s the modern steel industry was bolstered with the Bessemer process. The Bessemer process represented the first inexpensive method for mass production of steel pipe. Subsequently, seamless tube was born in 1895. Quickly followed by manufacturing of auto, bicycle, and machinery for oil production which began in full force.Koprak oka