blog

-

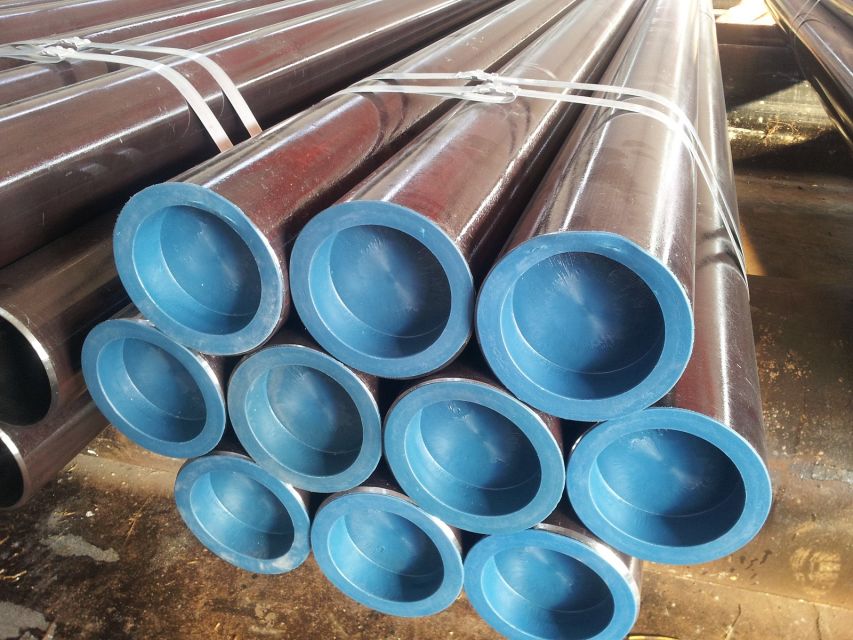

HOW THESE PIPES ARE MADE?-erw carbon steel pipe

Steel pipes are cylindrical steel tubes that are used in the manufacture and infrastructure of several different styles. They are the most used steel industry product. The key use of pipe is in the underground movement of liquid or gas, including oil, gas and water. However in the development and construction process pipes of different sizes are used. The narrow steel pipe that operates the cooling system in refrigerators is a typical example of household development. Building uses heating and plumbing tubing. It is possible to create structures using steel pipes of various sizes like handrails, bike racks or pipe pads.The pioneer of steel pipe fabricators is believed to be William Murdoch. In 1815 he mixed barrels of muskets with a burning system of coal lamps. In his revolutionary piping method, Murdoch used coal gas to be brought to lamps on London’s streets.Since the 1800’s, significant advances have been made in steel pipes technology, including the advancement of production processes, development of applications for their use and the development and qualification of regulations and standards.Consulte Mais informação -

lsaw tubo de aço-erw tubo de aço carbono

Tubos de aço de alta qualidade são produzidos a partir de três (3) processos de fabricação: Sem costura, LSAW (soldagem por arco submerso com costura longitudinal) e ERW (soldagem por resistência elétrica). Os tubos LSAW e ERW são altamente considerados pelos seus numerosos campos de aplicação. Eles são tremendamente usados em soluções e sistemas de fundação, construção naval, construção estrutural e diversas aplicações em projetos hídricos, indústria petroquímica, química e de energia, irrigação agrícola, construção urbana e muito mais.Consulte Mais informação -

How lsaw steel pipe made?-lsaw steel pipe

LSAW steel pipe (Longitudinally Submerged Arc Welding abbreviated as LSAW) is a professional expression term for LSAW steel pipe. It uses a single medium and thick plate as the raw material, and the steel plate is pressed (rolled) into a tube blank in a mold or a forming machine. The pipe is produced by submerged arc welding and expanded diameter.UOE LSAW pipe forming process:The three main forming processes of UOE LSAW steel pipe forming process include: steel plate pre-bending, U forming and O forming. Each process adopts a dedicated forming press to complete the three processes of pre-bending the edge of the steel plate, U forming and O forming in sequence to deform the steel plate into a circular tube.JCOE LSAW pipe forming process:Forming: After several steps of stamping on the JCO forming machine, first half of the steel plate is pressed into a "J" shape, then the other half of the steel plate is pressed into a "J" to form a "C" shape, and finally pressurized from the middle to form An open "O"-shaped tube blank is formed.Consulte Mais informação -

Tubo e tubo comparado com tubo de aço lsaw

O tubo de aço (e o tubo de aço) evoluiu ao longo da história. Especificamente, o tubo de metal existe desde cerca de 3.000 aC. Na verdade, os egípcios fizeram o primeiro tubo de metal de cobre. Já em 2.500 aC, os chineses usavam tubos de bambu como forma de transportar gás. Já em 2.500 aC, os chineses usavam tubos de bambu como forma de transportar gás natural para Pequim, sua capital. Roma e a Pérsia criaram aquedutos para levar água aos centros das cidades para tomar banho, lavar e beber. Além disso, o cano (ou tubulação) é feito com muitos materiais e métodos diferentes. Pedra oca, argila cozida, bambu, palmeira, sequóia, chumbo, bronze, cobre e borracha são apenas alguns dos materiais que compõem os tubos. Em meados de 1800, a indústria siderúrgica moderna foi reforçada com o processo Bessemer. O processo Bessemer representou o primeiro método barato para produção em massa de tubos de aço. Posteriormente, o tubo sem costura nasceu em 1895. Seguido rapidamente pela fabricação de automóveis, bicicletas e máquinas para produção de petróleo, que começou com força total.Consulte Mais informação -

HOW THESE PIPES ARE MADE?-lsaw steel pipe

Steel pipes are cylindrical steel tubes that are used in the manufacture and infrastructure of several different styles. They are the most used steel industry product. The key use of pipe is in the underground movement of liquid or gas, including oil, gas and water. However in the development and construction process pipes of different sizes are used. The narrow steel pipe that operates the cooling system in refrigerators is a typical example of household development. Building uses heating and plumbing tubing. It is possible to create structures using steel pipes of various sizes like handrails, bike racks or pipe pads.The pioneer of steel pipe fabricators is believed to be William Murdoch. In 1815 he mixed barrels of muskets with a burning system of coal lamps. In his revolutionary piping method, Murdoch used coal gas to be brought to lamps on London’s streets.Since the 1800’s, significant advances have been made in steel pipes technology, including the advancement of production processes, development of applications for their use and the development and qualification of regulations and standards.Consulte Mais informação -

tubo de aço lsaw - breve descrição e comparações de tubos LSAW, SSAW e ERW - tubo de aço lsaw

Tubos de aço de alta qualidade são produzidos a partir de três (3) processos de fabricação: Sem costura, LSAW (soldagem por arco submerso com costura longitudinal) e ERW (soldagem por resistência elétrica). Os tubos LSAW e ERW são altamente considerados pelos seus numerosos campos de aplicação. Eles são tremendamente usados em soluções e sistemas de fundação, construção naval, construção estrutural e diversas aplicações em projetos hídricos, indústria petroquímica, química e de energia, irrigação agrícola, construção urbana e muito mais.Consulte Mais informação -

LSAW Steel Pipe (Longitudinally Submerged Arc Welding Pipe) , DSAW Steel Pipe

LSAW steel pipe (Longitudinally Submerged Arc Welding abbreviated as LSAW) is a professional expression term for LSAW steel pipe. It uses a single medium and thick plate as the raw material, and the steel plate is pressed (rolled) into a tube blank in a mold or a forming machine. The pipe is produced by submerged arc welding and expanded diameter.UOE LSAW pipe forming process:The three main forming processes of UOE LSAW steel pipe forming process include: steel plate pre-bending, U forming and O forming. Each process adopts a dedicated forming press to complete the three processes of pre-bending the edge of the steel plate, U forming and O forming in sequence to deform the steel plate into a circular tube.JCOE LSAW pipe forming process:Forming: After several steps of stamping on the JCO forming machine, first half of the steel plate is pressed into a "J" shape, then the other half of the steel plate is pressed into a "J" to form a "C" shape, and finally pressurized from the middle to form An open "O"-shaped tube blank is formed.Consulte Mais informação -

What is LSAW and SSAW Pipe?-lsaw steel pipe-erw pipe

LSAW and SSAW are variants of SAW (submerged arc welded) pipes. The difference between them is the way they are welded. In LSAW pipes, the welding is longitudinal, which means that steel (hot rolled coil plate) is rolled into a pipe and the seam is welded longitudinally. In the SSAW type, steel coils are welded spirally, like a helix, so that the coil (strip) assumes the shape of a pipe. SAW pipes are used mainly in oil and gas transportation. On the other hand, seamless (non-welded) pipes are mainly application in oil and gas exploration projects.An LSAW pipe (“submerged arc welding”) is manufactured by cutting, bending, and welding steel plates (JCOE process). The two main types of LSAW pipes are the longitudinal (with a single or double straight seam weld, DSAW) and the spiral type (called, HSAW, SSAW or SAWL pipe).Consulte Mais informação -

LSAW Welded Steel Pipe: Features and Manufacturing Processes-lsaw steel pipe

LSAW (Longitudinal double submerge arc welding) carbon steel pipe is a type of SAW pipe made of steel plates that were hot rolled by JCOE or UOE forming technology. JCOE technology represents the shaping and forming processes involved during manufacturing as well as the inner and outer welding and cold expansion carried out after welding.When compared to UOE LSAW steel pipes, LSAW pipe manufacturers in China can produce more sizes as thus: OD 406 mm – 1620 mm, thickness 6.35 mm – 60 mm, pipe length 2 m – 18 m with the LSAW pipe having superiority.Octal offers LSAW steel pipe with high quality and competitive prices.Consulte Mais informação