Jan . 16, 2024 11:38 Back to list

Talk about LSAW Pipe-lsaw steel pipe

Talk about LSAW Pipe-lsaw steel pipe

Longitudinally Submerged Arc Welding Pipe is subdivided into UOE, RBE, JCOE steel pipe according to its different forming methods. Longitudinal high-frequency welded steel pipe has the characteristics of relatively simple process and fast continuous production, and has wide use in civil construction, petrochemical, light industry and other sectors. Mostly used to transport low pressure fluids or made into various engineering components and light industrial products.

LSAW (Longitudinally Submerged Arc Welded Steel pipes) in leaflets plate as raw material, the steel plate in the mold or molding machine pressure (volume) into using double-sided submerged arc welding and flaring from production.

Features:

- Large diameter steel pipes

- Thick walls

- High-Pressure resistance

- Low-temperature resistance can only use one HS code to declare the pipe fitting. But the straight tubes can not be used with one HS code.

API 5L Pipe Line, Oil & Gas LinePipe, LSAW Steel Pipe

Q345B steel polishing method

Polishing means a processing method by the action of mechanical, chemical or electrochemical, lower the q345b steel pipe surface roughness, to obtain a bright and smooth surface, and surface modification process making use of a flexible polishing tools and polishing abrasive particles or other media on the workpiece.

Q345B steel polishing method often used Polishing means a processing method by the action of mechanical, chemical or electrochemical, lower the q345b steel pipe surface roughness, to obtain a bright and smooth surface, and surface modification process making use of a flexible polishing tools and polishing abrasive particles or other media on the workpiece.

Polishing can not improve the dimensional accuracy or geometrical shape accuracy of q345b steel pipe, but can obtain a smooth surface or specular gloss, sometimes to be used to eliminate gloss. Usually buff as a polishing tool. Buff is generally made with multilayer canvas, leather crafted stacked, on both sides clamped with a metal circular plate, its rim coated abrasive mixture of powder and oil and other uniform.

(1) Mechanical q345b steel polishing surface corrosion resistance. As we know, the mechanical polishing q345b steel corrosion resistance is significantly lower than the electrochemical polishing q345b steel pipe, mainly due to the cold mechanical q345b polishing surface hardened steel deformed layer high corrosion rate, coupled with in the mechanical polishing process, inevitably have abrasive particles embedded in the deformable layer, the corrosion rate of deformation layer increased greatly.

(2) electrochemical q345b steel polishing makes the metal surface hardening layer easy to be dissolved, and can lower the surface activity, what’s more, there is a continuous passivation film formed on the surface, significantly improved the corrosion resistance.

Mechanical Properties of Chinese low alloy steel: Q345B

Q345B steel is a Chinese standardized low alloy, medium tensile strength steel made with a hot-rolling process, and is used for a number of manufacturing purposes. It is a steel with less than 0.2 percent of its composition made up of carbon, less than 0.55 percent of its composition made of silicon and several impurities (mostly sulfur, chromium and nickel). This particular grade of steel is a ‘general purpose’ manufacturing steel in construction equipment field, such as Q345B is basic mateiral of making excavator bucket and long boom arms.

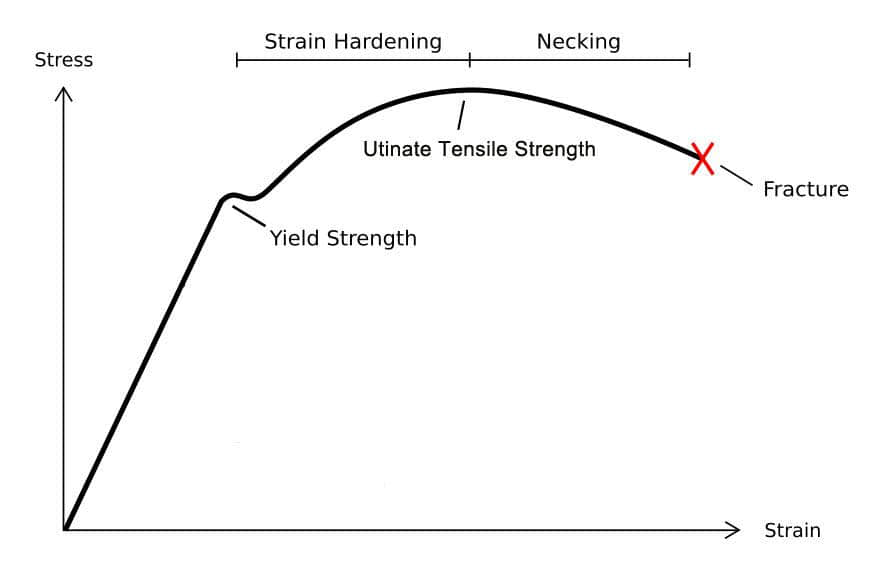

Mechnical property for Q345B low alloy structural steel:

1, Yield Strength

A yield strength or yield point is the material property defined as the stress at which a material begins to deform plastically. Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed, Yield strength of Q345B is 345 MegaPascals. Like most steels of its grade, it suffers elongation before it pulls apart, typically at 20-21 percent of its initial length.

2, Tensile strength

The tensile strength of a material is the maximum amount of tensile stress that it can take before failure, for example breaking. Steel tensile strength is expressed in units of force divided by cross sectional area; in the Metric system, this unit is known as the Pascal. One Pascal is a Newton (the force needed to accelerate a one kilogram object to a velocity of one meter per second) per square meter. The tensile strength of Q345B steel is rated at 470 to 660 MegaPascals (where mega is million).

Steel tensile strength is expressed in units of force divided by cross sectional area; in the Metric system, this unit is known as the Pascal. One Pascal is a Newton (the force needed to accelerate a one kilogram object to a velocity of one meter per second) per square meter. The tensile strength of Q345B steel is rated at 470 to 630 MegaPascals (where mega is million) and a yield strength (where the material starts to thin and pull like taffy) at 345 MegaPascals. Like most steels of its grade, it suffers elongation before it pulls apart, typically at 20-21 percent of its initial length.

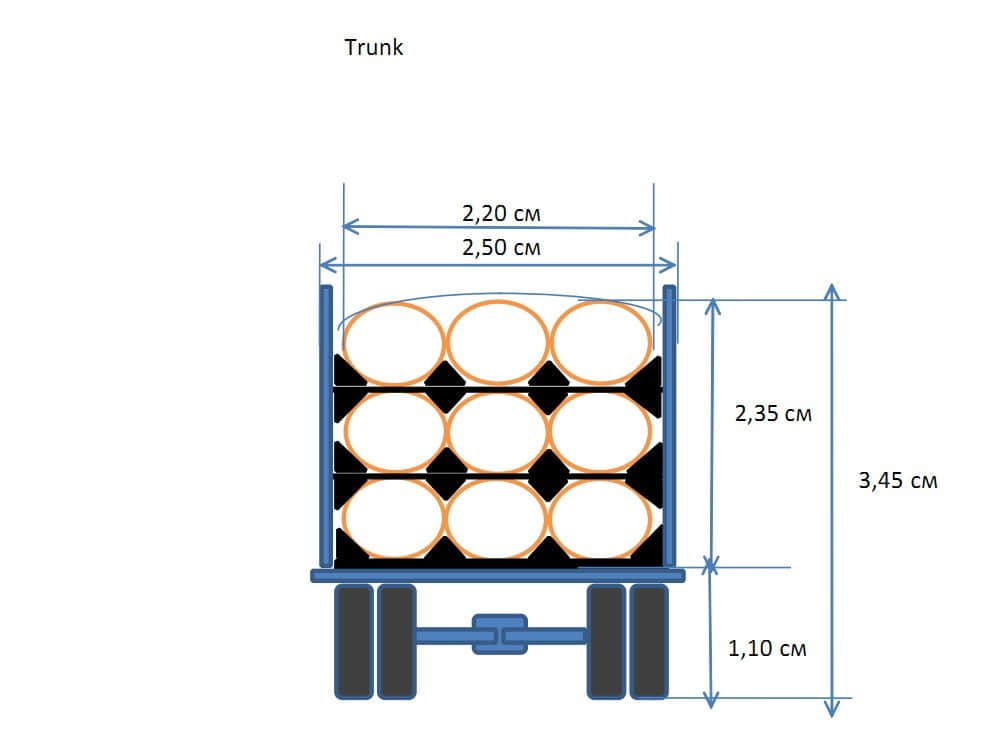

LSAW pipes Production Range

LSAW (Longitudinally Submerged Arc Welded Steel pipes) in leaflets plate as raw material, the steel plate in the mold or molding machine pressure (volume) into using double-sided submerged arc welding and flaring from production.

- Legnth:8-12.15m

- Material: API 5L Gr.B-X80

- Standard: API spec. 5L; GB9711.1-97

Range of LSAW pipes applied in construction

Range of roller pipes:

- Outer diameter: Ф1200-3800mm

- Wall thickness: 12-120mm

- Unit length (max) 3.2m.

Note: The specification in the table is available to Q345.

Remarks:non-standard dimensions pipes can be produced to customer specifications.

Chemical Composition& Mechanical Properties

| Standard | Grade | Chemical Composition (max)% | Mechanical Properties (min) | |||||

| C | Mn | Si | S | P | Yield Strength | Tensile Strength | ||

| (Mpa) | (Mpa) | |||||||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.05 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.04 | 0.04 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.03 | 0.03 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.03 | 0.03 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.05 | 0.05 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.05 | 0.05 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.04 | 0.04 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0.05 | 0.05 | 235 | 400 |

| SS490 | - | - | - | 0.05 | 0.05 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Range of Roller Pipes

| Number | Technical parameter | Unit | HQW11s-120X3200 | ||

|---|---|---|---|---|---|

| 1 | Material yield limited | Mpa | 245 | 345 | 345 |

| 2 | Wall thickness | mm | 120 | 100 | 110 |

| 3 | Maximum pre-bending thickness | mm | 110 | 90 | 100 |

| 4 | Maximum width of steel plate | mm | 3200 | 3200 | 3200 |

| 5 | Minimum diameter of fully loaded rolling steel plate | mm | 2500 | 1600 | 1600 |

The developing trend of LSAW steel pipe

The developing trend of LSAW steel pipe in the future:

- in terms of the onshore gas,with the large diameter LSAW steel pipe, its single-tube gas transmission capacity could reach the level of 50 billion cubic meters / year, pipe diameter can reach ф1422mm, steel grade achieve X80, and gas transmission pressure can reach 12MPa;

- in terms of the ocean steel pipe, the gas pipeline develops towards the direction of deep-sea pipeline (> 1500 meters), marine structural tube towards the direction of high-intensity, large wall thickness, for example ф610mm×31.8mm, X65 grade;

- in terms of business management, plate and pipe integration (steelmaking – Continuous Casting – rolled plate – pipe manufacturing) is the future development trend, for example in Japan and India plate and strip production line is always equipped with a welded steel pipe unit;

- entering the market of high-grade structural tubes, this is an important question to be considered by the LSAW steel pipe production line manufacturer when deploying the device, so it is necessary to set the preheating device before pre-welding, or set the heat treatment process and so on;

- in marketing, in addition to oil and gas pipelines, there is slurry pipelines;

- anti HIC tube and anti deformed tube are with a considerable market prospect, can be used to transport acid gases and improve the ability against external environmental damage in harsh geological conditions (landslides, mudslides, earthquakes).

Application of LSAW pipe

LSAW pipe is used to convey low-pressure liquid or high-pressure petroleum or natural gas and can also be used widely in structural supports or foundations.

Base on its advantage of high reliability and safety performance, the LSAW pipe is widely used in various pipelines engineering and construction, even under the most severe condition, and also can be used in engineering of chemical industry, electric power, irrigation, construction and piling etc.

The advantage for the LSAW type is that they could produce more thick wall thickness of pipes, maximum to 120 mm.

Our technical support for ERW steel pipe , SSAW steel pipe & LSAW stel pipe

Gas pipeline by pipe process can be divided into seamless steel pipe (SMLS), ERW steel pipe SSW steel pipe ,LSAW steel pipe ,HFW steel pipe etc…

Mainly as a field gathering pipe and internal high-pressure natural gas pipeline of small-caliber, long-distance pipelines for oil and gas a small number, the vast majority of long-distance pipeline is the use of high-frequency straight seam welded pipe (ERW), spiral submerged arc welded pipe (SSAW), LSAW steel pipe (LSAW) three.

The following table shows the characteristics of several steel process and quality performance comparison:

Straight seam high frequency welded pipe (ERW steel pipe) by welding and induction welding is divided into different exposure to welding in two forms, using broadband hot-rolled coils as raw materials, pre-curved, continuous molding, welding, heat treatment, sizing, straightening, cutting and other processes, and spiral welded pipe weld compared to the short, high dimensional accuracy, uniform thickness, surface quality, the advantages of higher pressure, but the drawback is that only produce small-caliber thin-walled tube, easy to produce weldsgray leaf spot, not fusion, groove-shaped corrosion defects. At present more extensive application areas of the city gas, crude oil transportation and so on.

Spiral submerged arc welded pipe (SSAW steel pipe) is the strip volume control when the forward direction and forming a molding pipe centerline angle (adjustable), side molding edge welding, the weld into a spiral, the advantage of the same specifications of the strip can beproduction of a variety of diameters of pipe, meet a wider range of raw materials, welds can avoid the main stress, the force is better, the disadvantage is poor geometry,the weld seam length compared to the straight pipe length, easy to produce cracks, pores, slag, welding and other welding defects side, welding stress was tensile stress state.General long-distance gas pipeline design specification spiral submerged arc welded pipe can only be used for Class 3, Class 4 area.

Foreign raw materials will be changed to improve this process steel, so that separate forming and welding, the welding and lean pre-, post-weld cold-expanding, then the quality of welding close to the UOE pipe, currently there is no such process,is the spiralFactory directions for improvement. “Natural Gas” is still used by the traditional spiral process of production, but the tube side of the expander.United States, Japan and Germany in general negative SSAW, that trunk should not use SSAW; Canada and Italy, some use SSAW, Russia, a small amount of use SSAW, and have developed a very strict additional conditions, due to historical reasons, most still use the main trunk domestic SSAW. LSAW pipe (LSAW) is a single plate as raw material, steel in the mold or molding machine pressure (volume) into the tube, using double-sided submerged arc welding method and Expanding from the produce.

In the construction of high-strength, high toughness, high-quality long-distance gas pipeline, most of the required large diameter thick wall steel pipe LSAW pipe.According to API standards, in large oil and gas pipelines, when through the alpine zone, sea, cities and other densely populated areas Class 1, Class 2 areas, LSAW pipe is the only designated suitable tube.By forming different ways can be divided into:

- UOE welded pipe: sheet steel at the edge of the pre-bend, the U shape, O shape, welded inside and outside welding, mechanical cold Expanding processes;

- JCOE pipe: ie “JCOE” pre-welding, forming, welding and other processes by the cold expander;

- HME pipe: the mandrel rolling basis over the “CCO” forming, welding and other processes by the cold expander.

The wide range of product specifications, weld toughness, ductility, good uniformity and dense, with a large diameter, wall thickness, high pressure, low temperature corrosion resistance and other advantages.

Welded pipes specification and size

API SPEC 5CT

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Casting | API 5CT | Ø48.3~273 x WT2.77~11.43 | J55, K55, N80, L80 |

| Tubing | API 5CT | Ø48.3~273 x WT2.77~11.43 | J55, K55, N80, L80, H40 |

API SPEC 5L

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Line Pipes | API 5L | Ø60.3~273.1 x WT2.77~12.7 | A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 |

ASTM / ASME

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Electric-Resistance-Welded Steel Pipes | ASTM A135 | Ø42.2~114.3 x WT2.11~2.63 | A |

| Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes | ASTM A178 | 42.2-114.3 x 2.11-2.63 | A, C, D |

| ERW and Hot-dip Galvanized Steel Pipes | ASTM A53 | Ø21.3~273 x WT2.11~12.7 | A, B |

| Pipes for Piling Usage | ASTM A252 | Ø219.1~508 x WT3.6~12.7 | Gr.2, Gr.3 |

| Tubes for General Structural Purpose | ASTM A500 | Ø21.3~273 x WT2.11~12.7 | Gr.2, Gr.3 |

| Square Pipes for General Structural Purpose | ASTM A500 | 25 x 25~160 x 160 x WT1.2~8.0 | Carbon Steel |

DIN

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Threaded Steel Pipes | DIN 2440 | Ø21~164 x WT2.65~4.85 | Carbon Steel |

BS

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Screwed and Socketed Steel Tubes | BS 1387 | Ø21.4~113.9 x WT2~3.6 | Carbon Steel |

EN

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Scaffolding Pipes | EN 39 | Ø48.3 x WT3.2~4 | Carbon Steel |

JIS

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Carbon Steel Tubes for General Structure Purpose | JIS G3444 | Ø21.7~216.3 x WT2.0~6.0 | Carbon Steel |

| Carbon Steel Tubes for Machine Structure Purpose | JIS G3445 | Ø15~76 x WT0.7~3.0 | STKM11A, STKM13A |

| Carbon Steel Pipes for Ordinary Piping | JIS G3452 | Ø21.9~216.3 x WT2.8~5.8 | Carbon Steel |

| Carbon Steel Pipes for Pressure Service | JIS G3454 | Ø21.7~216.3 x WT2.8~7.1 | Carbon Steel |

| Carbon Steel Rigid Steel Conduits | JIS G8305 | Ø21~113.4 x WT1.2~3.5 | G16~G104, C19~C75, E19~E75 |

| Carbon Steel Rectangular Pipes for General Structure | JIS G3466 | 16 x 16~150 x 150 x WT0.7~6 | Carbon Steel |

Coating

Pipeline coating is the most consistent and successful solution for protecting ERW pipes from corrosion, from moisture, other harmful chemicals.

Anti-corrosion steel pipe is processed through the preservation process, which can effectively prevent or slow down the process in the transport and use of chemical or electrochemical corrosion reaction of steel pipe.

Therefore pipe anti-corrosion layer is an important barrier to prevent soil erosion. A well-known foreign scholar put forward” 3PE france protective layer”, so far, anti-corrosion methods is widely used.

Coated pipes offer high resistance to corrosion on pipes and provide many benefits such as:

- Increased Flow Capacity – A coating on pipes helps provide a smoother surface thus improving gas and liquid flow within pipes.

- Reduced Cost – The pipeline coating increases the pipes durability so they can be deployed with minimum maintenance cost even in the harshest environments.

- Lower energy usage – Various studies have shown that pipelines that are internally coated use less energy for pumping and compression of products through pipes. This helps in increased saving over time.

- Clean delivery of products – The inhibitors used for the protection products can also be minimized by the use of coated pipes for delivery of products.

- Thus, coating of pipelines can help you in reducing your maintenance cost and at the same time providing a corrosion free reliable protection.

Basic functions of erw pipe coating

- making the surface of ERW steel pipes free from electrochemical corrosion of the soil medium, the basic physics of bacterial corrosion protection.

- resisting the move of the soil medium creep stress, static stress and abrasion force method and structure of the basic machinery protection.

The basic principles of urban gas pipeline coating selection:

- good insulating and mechanical properties;

- good resistance to cathodic disbondment performance;

- good resistance to water, gas permeability;

- good chemical resistance soaking performance and anti-aging properties;

- resistance to low temperature and high temperature performance;

- easy mending and mending;

- at reasonable prices.

-

Carbon Steel Tube Pressure Rating-steel pie

NewsJan.16,2024

-

Stainless steel-Electric Resistance Welded (ERW) Pipe-Welded (ERW) Pipe

NewsJan.16,2024

-

High Frequency Electric Weld (ERW) Line Pipe and Standard Products-ERW Steel Pipe

NewsJan.16,2024

-

How Is Steel Tubing Made?-Steel Tubing

NewsJan.16,2024

-

Structural steel Pipe-ERW Steel Pipe

NewsJan.16,2024

-

Methods of Manufacturing used in the Metal Pipe and Tubing Industries-ERW Steel Pipe

NewsJan.16,2024

Jan . 16, 2024 11:18 Back to list

Talk about LSAW Pipe-lsaw steel pipe

Talk about LSAW Pipe-lsaw steel pipe

Longitudinally Submerged Arc Welding Pipe is subdivided into UOE, RBE, JCOE steel pipe according to its different forming methods. Longitudinal high-frequency welded steel pipe has the characteristics of relatively simple process and fast continuous production, and has wide use in civil construction, petrochemical, light industry and other sectors. Mostly used to transport low pressure fluids or made into various engineering components and light industrial products.

LSAW (Longitudinally Submerged Arc Welded Steel pipes) in leaflets plate as raw material, the steel plate in the mold or molding machine pressure (volume) into using double-sided submerged arc welding and flaring from production.

Features:

- Large diameter steel pipes

- Thick walls

- High-Pressure resistance

- Low-temperature resistance can only use one HS code to declare the pipe fitting. But the straight tubes can not be used with one HS code.

API 5L Pipe Line, Oil & Gas LinePipe, LSAW Steel Pipe

Q345B steel polishing method

Polishing means a processing method by the action of mechanical, chemical or electrochemical, lower the q345b steel pipe surface roughness, to obtain a bright and smooth surface, and surface modification process making use of a flexible polishing tools and polishing abrasive particles or other media on the workpiece.

Q345B steel polishing method often used Polishing means a processing method by the action of mechanical, chemical or electrochemical, lower the q345b steel pipe surface roughness, to obtain a bright and smooth surface, and surface modification process making use of a flexible polishing tools and polishing abrasive particles or other media on the workpiece.

Polishing can not improve the dimensional accuracy or geometrical shape accuracy of q345b steel pipe, but can obtain a smooth surface or specular gloss, sometimes to be used to eliminate gloss. Usually buff as a polishing tool. Buff is generally made with multilayer canvas, leather crafted stacked, on both sides clamped with a metal circular plate, its rim coated abrasive mixture of powder and oil and other uniform.

(1) Mechanical q345b steel polishing surface corrosion resistance. As we know, the mechanical polishing q345b steel corrosion resistance is significantly lower than the electrochemical polishing q345b steel pipe, mainly due to the cold mechanical q345b polishing surface hardened steel deformed layer high corrosion rate, coupled with in the mechanical polishing process, inevitably have abrasive particles embedded in the deformable layer, the corrosion rate of deformation layer increased greatly.

(2) electrochemical q345b steel polishing makes the metal surface hardening layer easy to be dissolved, and can lower the surface activity, what’s more, there is a continuous passivation film formed on the surface, significantly improved the corrosion resistance.

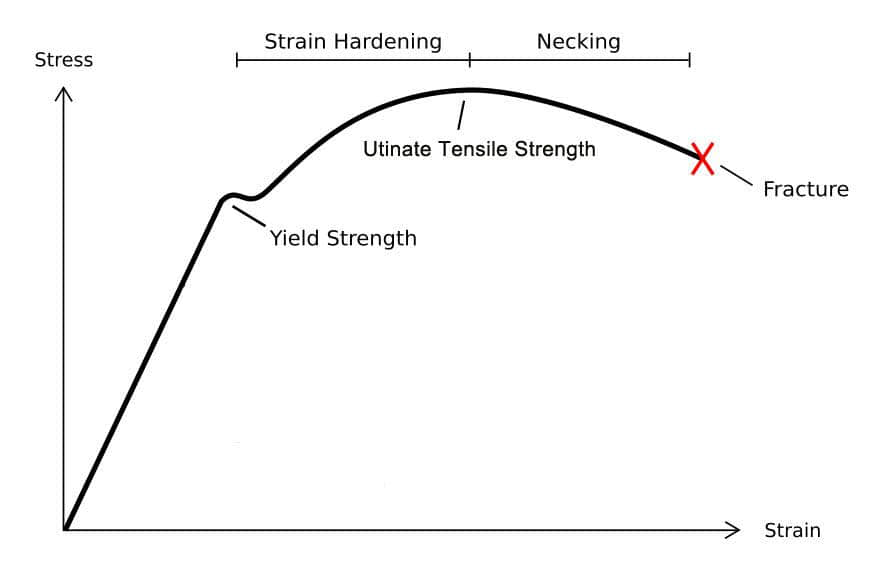

Mechanical Properties of Chinese low alloy steel: Q345B

Q345B steel is a Chinese standardized low alloy, medium tensile strength steel made with a hot-rolling process, and is used for a number of manufacturing purposes. It is a steel with less than 0.2 percent of its composition made up of carbon, less than 0.55 percent of its composition made of silicon and several impurities (mostly sulfur, chromium and nickel). This particular grade of steel is a ‘general purpose’ manufacturing steel in construction equipment field, such as Q345B is basic mateiral of making excavator bucket and long boom arms.

Mechnical property for Q345B low alloy structural steel:

1, Yield Strength

A yield strength or yield point is the material property defined as the stress at which a material begins to deform plastically. Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed, Yield strength of Q345B is 345 MegaPascals. Like most steels of its grade, it suffers elongation before it pulls apart, typically at 20-21 percent of its initial length.

2, Tensile strength

The tensile strength of a material is the maximum amount of tensile stress that it can take before failure, for example breaking. Steel tensile strength is expressed in units of force divided by cross sectional area; in the Metric system, this unit is known as the Pascal. One Pascal is a Newton (the force needed to accelerate a one kilogram object to a velocity of one meter per second) per square meter. The tensile strength of Q345B steel is rated at 470 to 660 MegaPascals (where mega is million).

Steel tensile strength is expressed in units of force divided by cross sectional area; in the Metric system, this unit is known as the Pascal. One Pascal is a Newton (the force needed to accelerate a one kilogram object to a velocity of one meter per second) per square meter. The tensile strength of Q345B steel is rated at 470 to 630 MegaPascals (where mega is million) and a yield strength (where the material starts to thin and pull like taffy) at 345 MegaPascals. Like most steels of its grade, it suffers elongation before it pulls apart, typically at 20-21 percent of its initial length.

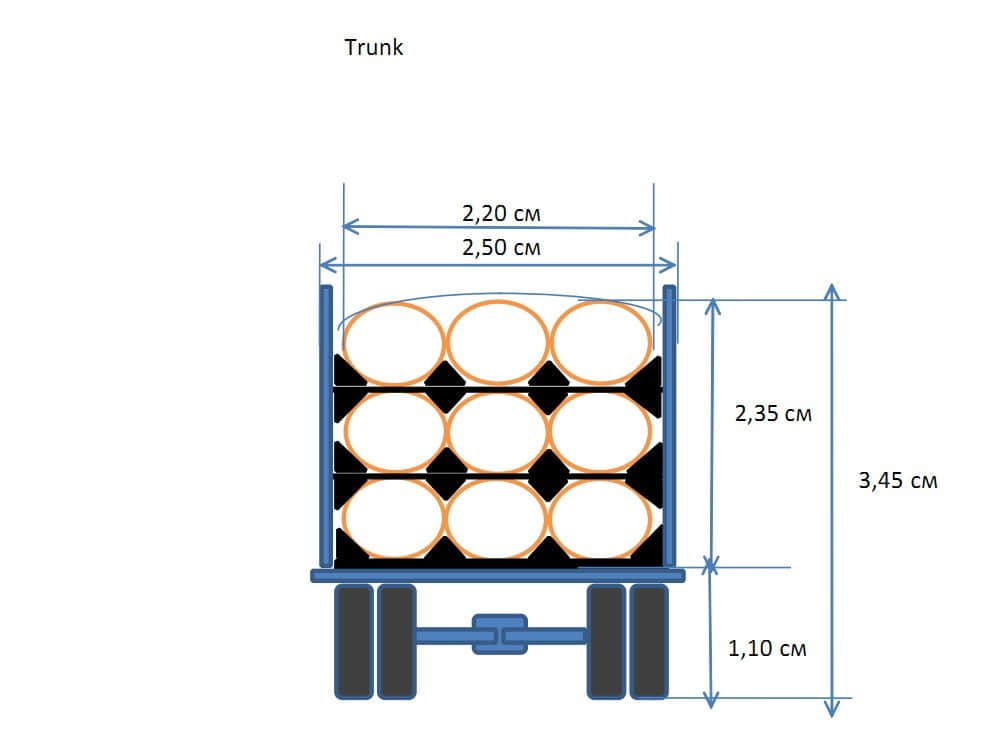

LSAW pipes Production Range

LSAW (Longitudinally Submerged Arc Welded Steel pipes) in leaflets plate as raw material, the steel plate in the mold or molding machine pressure (volume) into using double-sided submerged arc welding and flaring from production.

- Legnth:8-12.15m

- Material: API 5L Gr.B-X80

- Standard: API spec. 5L; GB9711.1-97

Range of LSAW pipes applied in construction

Range of roller pipes:

- Outer diameter: Ф1200-3800mm

- Wall thickness: 12-120mm

- Unit length (max) 3.2m.

Note: The specification in the table is available to Q345.

Remarks:non-standard dimensions pipes can be produced to customer specifications.

Chemical Composition& Mechanical Properties

| Standard | Grade | Chemical Composition (max)% | Mechanical Properties (min) | |||||

| C | Mn | Si | S | P | Yield Strength | Tensile Strength | ||

| (Mpa) | (Mpa) | |||||||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.05 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.04 | 0.04 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.03 | 0.03 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.03 | 0.03 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.05 | 0.05 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.05 | 0.05 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.04 | 0.04 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0.05 | 0.05 | 235 | 400 |

| SS490 | - | - | - | 0.05 | 0.05 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Range of Roller Pipes

| Number | Technical parameter | Unit | HQW11s-120X3200 | ||

|---|---|---|---|---|---|

| 1 | Material yield limited | Mpa | 245 | 345 | 345 |

| 2 | Wall thickness | mm | 120 | 100 | 110 |

| 3 | Maximum pre-bending thickness | mm | 110 | 90 | 100 |

| 4 | Maximum width of steel plate | mm | 3200 | 3200 | 3200 |

| 5 | Minimum diameter of fully loaded rolling steel plate | mm | 2500 | 1600 | 1600 |

The developing trend of LSAW steel pipe

The developing trend of LSAW steel pipe in the future:

- in terms of the onshore gas,with the large diameter LSAW steel pipe, its single-tube gas transmission capacity could reach the level of 50 billion cubic meters / year, pipe diameter can reach ф1422mm, steel grade achieve X80, and gas transmission pressure can reach 12MPa;

- in terms of the ocean steel pipe, the gas pipeline develops towards the direction of deep-sea pipeline (> 1500 meters), marine structural tube towards the direction of high-intensity, large wall thickness, for example ф610mm×31.8mm, X65 grade;

- in terms of business management, plate and pipe integration (steelmaking – Continuous Casting – rolled plate – pipe manufacturing) is the future development trend, for example in Japan and India plate and strip production line is always equipped with a welded steel pipe unit;

- entering the market of high-grade structural tubes, this is an important question to be considered by the LSAW steel pipe production line manufacturer when deploying the device, so it is necessary to set the preheating device before pre-welding, or set the heat treatment process and so on;

- in marketing, in addition to oil and gas pipelines, there is slurry pipelines;

- anti HIC tube and anti deformed tube are with a considerable market prospect, can be used to transport acid gases and improve the ability against external environmental damage in harsh geological conditions (landslides, mudslides, earthquakes).

Application of LSAW pipe

LSAW pipe is used to convey low-pressure liquid or high-pressure petroleum or natural gas and can also be used widely in structural supports or foundations.

Base on its advantage of high reliability and safety performance, the LSAW pipe is widely used in various pipelines engineering and construction, even under the most severe condition, and also can be used in engineering of chemical industry, electric power, irrigation, construction and piling etc.

The advantage for the LSAW type is that they could produce more thick wall thickness of pipes, maximum to 120 mm.

Our technical support for ERW steel pipe , SSAW steel pipe & LSAW stel pipe

Gas pipeline by pipe process can be divided into seamless steel pipe (SMLS), ERW steel pipe SSW steel pipe ,LSAW steel pipe ,HFW steel pipe etc…

Mainly as a field gathering pipe and internal high-pressure natural gas pipeline of small-caliber, long-distance pipelines for oil and gas a small number, the vast majority of long-distance pipeline is the use of high-frequency straight seam welded pipe (ERW), spiral submerged arc welded pipe (SSAW), LSAW steel pipe (LSAW) three.

The following table shows the characteristics of several steel process and quality performance comparison:

Straight seam high frequency welded pipe (ERW steel pipe) by welding and induction welding is divided into different exposure to welding in two forms, using broadband hot-rolled coils as raw materials, pre-curved, continuous molding, welding, heat treatment, sizing, straightening, cutting and other processes, and spiral welded pipe weld compared to the short, high dimensional accuracy, uniform thickness, surface quality, the advantages of higher pressure, but the drawback is that only produce small-caliber thin-walled tube, easy to produce weldsgray leaf spot, not fusion, groove-shaped corrosion defects. At present more extensive application areas of the city gas, crude oil transportation and so on.

Spiral submerged arc welded pipe (SSAW steel pipe) is the strip volume control when the forward direction and forming a molding pipe centerline angle (adjustable), side molding edge welding, the weld into a spiral, the advantage of the same specifications of the strip can beproduction of a variety of diameters of pipe, meet a wider range of raw materials, welds can avoid the main stress, the force is better, the disadvantage is poor geometry,the weld seam length compared to the straight pipe length, easy to produce cracks, pores, slag, welding and other welding defects side, welding stress was tensile stress state.General long-distance gas pipeline design specification spiral submerged arc welded pipe can only be used for Class 3, Class 4 area.

Foreign raw materials will be changed to improve this process steel, so that separate forming and welding, the welding and lean pre-, post-weld cold-expanding, then the quality of welding close to the UOE pipe, currently there is no such process,is the spiralFactory directions for improvement. “Natural Gas” is still used by the traditional spiral process of production, but the tube side of the expander.United States, Japan and Germany in general negative SSAW, that trunk should not use SSAW; Canada and Italy, some use SSAW, Russia, a small amount of use SSAW, and have developed a very strict additional conditions, due to historical reasons, most still use the main trunk domestic SSAW. LSAW pipe (LSAW) is a single plate as raw material, steel in the mold or molding machine pressure (volume) into the tube, using double-sided submerged arc welding method and Expanding from the produce.

In the construction of high-strength, high toughness, high-quality long-distance gas pipeline, most of the required large diameter thick wall steel pipe LSAW pipe.According to API standards, in large oil and gas pipelines, when through the alpine zone, sea, cities and other densely populated areas Class 1, Class 2 areas, LSAW pipe is the only designated suitable tube.By forming different ways can be divided into:

- UOE welded pipe: sheet steel at the edge of the pre-bend, the U shape, O shape, welded inside and outside welding, mechanical cold Expanding processes;

- JCOE pipe: ie “JCOE” pre-welding, forming, welding and other processes by the cold expander;

- HME pipe: the mandrel rolling basis over the “CCO” forming, welding and other processes by the cold expander.

The wide range of product specifications, weld toughness, ductility, good uniformity and dense, with a large diameter, wall thickness, high pressure, low temperature corrosion resistance and other advantages.

Welded pipes specification and size

API SPEC 5CT

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Casting | API 5CT | Ø48.3~273 x WT2.77~11.43 | J55, K55, N80, L80 |

| Tubing | API 5CT | Ø48.3~273 x WT2.77~11.43 | J55, K55, N80, L80, H40 |

API SPEC 5L

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Line Pipes | API 5L | Ø60.3~273.1 x WT2.77~12.7 | A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 |

ASTM / ASME

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Electric-Resistance-Welded Steel Pipes | ASTM A135 | Ø42.2~114.3 x WT2.11~2.63 | A |

| Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes | ASTM A178 | 42.2-114.3 x 2.11-2.63 | A, C, D |

| ERW and Hot-dip Galvanized Steel Pipes | ASTM A53 | Ø21.3~273 x WT2.11~12.7 | A, B |

| Pipes for Piling Usage | ASTM A252 | Ø219.1~508 x WT3.6~12.7 | Gr.2, Gr.3 |

| Tubes for General Structural Purpose | ASTM A500 | Ø21.3~273 x WT2.11~12.7 | Gr.2, Gr.3 |

| Square Pipes for General Structural Purpose | ASTM A500 | 25 x 25~160 x 160 x WT1.2~8.0 | Carbon Steel |

DIN

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Threaded Steel Pipes | DIN 2440 | Ø21~164 x WT2.65~4.85 | Carbon Steel |

BS

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Screwed and Socketed Steel Tubes | BS 1387 | Ø21.4~113.9 x WT2~3.6 | Carbon Steel |

EN

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Scaffolding Pipes | EN 39 | Ø48.3 x WT3.2~4 | Carbon Steel |

JIS

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Carbon Steel Tubes for General Structure Purpose | JIS G3444 | Ø21.7~216.3 x WT2.0~6.0 | Carbon Steel |

| Carbon Steel Tubes for Machine Structure Purpose | JIS G3445 | Ø15~76 x WT0.7~3.0 | STKM11A, STKM13A |

| Carbon Steel Pipes for Ordinary Piping | JIS G3452 | Ø21.9~216.3 x WT2.8~5.8 | Carbon Steel |

| Carbon Steel Pipes for Pressure Service | JIS G3454 | Ø21.7~216.3 x WT2.8~7.1 | Carbon Steel |

| Carbon Steel Rigid Steel Conduits | JIS G8305 | Ø21~113.4 x WT1.2~3.5 | G16~G104, C19~C75, E19~E75 |

| Carbon Steel Rectangular Pipes for General Structure | JIS G3466 | 16 x 16~150 x 150 x WT0.7~6 | Carbon Steel |

Coating

Pipeline coating is the most consistent and successful solution for protecting ERW pipes from corrosion, from moisture, other harmful chemicals.

Anti-corrosion steel pipe is processed through the preservation process, which can effectively prevent or slow down the process in the transport and use of chemical or electrochemical corrosion reaction of steel pipe.

Therefore pipe anti-corrosion layer is an important barrier to prevent soil erosion. A well-known foreign scholar put forward” 3PE france protective layer”, so far, anti-corrosion methods is widely used.

Coated pipes offer high resistance to corrosion on pipes and provide many benefits such as:

- Increased Flow Capacity – A coating on pipes helps provide a smoother surface thus improving gas and liquid flow within pipes.

- Reduced Cost – The pipeline coating increases the pipes durability so they can be deployed with minimum maintenance cost even in the harshest environments.

- Lower energy usage – Various studies have shown that pipelines that are internally coated use less energy for pumping and compression of products through pipes. This helps in increased saving over time.

- Clean delivery of products – The inhibitors used for the protection products can also be minimized by the use of coated pipes for delivery of products.

- Thus, coating of pipelines can help you in reducing your maintenance cost and at the same time providing a corrosion free reliable protection.

Basic functions of erw pipe coating

- making the surface of ERW steel pipes free from electrochemical corrosion of the soil medium, the basic physics of bacterial corrosion protection.

- resisting the move of the soil medium creep stress, static stress and abrasion force method and structure of the basic machinery protection.

The basic principles of urban gas pipeline coating selection:

- good insulating and mechanical properties;

- good resistance to cathodic disbondment performance;

- good resistance to water, gas permeability;

- good chemical resistance soaking performance and anti-aging properties;

- resistance to low temperature and high temperature performance;

- easy mending and mending;

- at reasonable prices.

-

Carbon Steel Tube Pressure Rating-steel pie

NewsJan.16,2024

-

Stainless steel-Electric Resistance Welded (ERW) Pipe-Welded (ERW) Pipe

NewsJan.16,2024

-

High Frequency Electric Weld (ERW) Line Pipe and Standard Products-ERW Steel Pipe

NewsJan.16,2024

-

How Is Steel Tubing Made?-Steel Tubing

NewsJan.16,2024

-

Structural steel Pipe-ERW Steel Pipe

NewsJan.16,2024

-

Methods of Manufacturing used in the Metal Pipe and Tubing Industries-ERW Steel Pipe

NewsJan.16,2024