Blog

-

Carbon Steel Tube Pressure Rating-steel pie

Carbon steel tube is an economic steel, the product of steel and its variety of specifications are extremely wide, and its performance requirements are also varied.Baca lagi -

Stainless steel-Electric Resistance Welded (ERW) Pipe-Welded (ERW) Pipe

Steel pipes come in many forms and sizes. Seamless pipes are a non-welded option produced from hollowed-out steel billets. When it comes to welded steel pipes, there are three options: ERW, LSAW and SSAW.ERW pipes are made from electric resistance welded steel plates. LSAW pipes are made from longitudinally submerged arc welded steel plates. SSAW pipes are made from spiral submerged arc welded steel plates.Steel pipes are typically used in the oil and gas industry for exploration and extraction (upstream), the transmission of fluids like oil, gas and slurries (midstream) and oil refinement into derivative products (downstream). They are also used for agricultural irrigation, urban construction and more.Let’s take a closer look at each type of pipe, comparing their differences and how to make an order with the right description.Baca lagi -

Paip Talian Kimpalan Elektrik (ERW) Frekuensi Tinggi dan Produk Standard-Paip Keluli ERW

Paip talian kimpalan elektrik frekuensi tinggi (ERW) Produk Keluli AS dan produk paip kimpalan rintangan elektrik standard siap dengan lancar dan berdinding nipis. Ia dihasilkan dengan terus membentuk jalur bergulung panas bergelung ke dalam tiub dan mengimpal jahitan membujur menggunakan kimpalan rintangan elektrik frekuensi tinggi. Keperluan sifat kimia dan mekanikal adalah seperti yang ditetapkan oleh API 5L semasa dan piawaian ASTM yang berkenaan. Paip standard ERW dan paip talian dikimpal elektrik frekuensi tinggi digunakan secara meluas di seluruh industri minyak dan gas, serta untuk cerucuk paip dan sistem paip kabel. Dengan lebih seabad menghasilkan produk keluli untuk perniagaan tenaga, Produk Tiub Keluli AS menawarkan pelbagai kaedah pembuatan untuk menghasilkan paip keluli yang boleh memenuhi keperluan khusus pelanggan kami. Hubungi kami untuk mencari keluli yang sesuai untuk permohonan anda.Baca lagi -

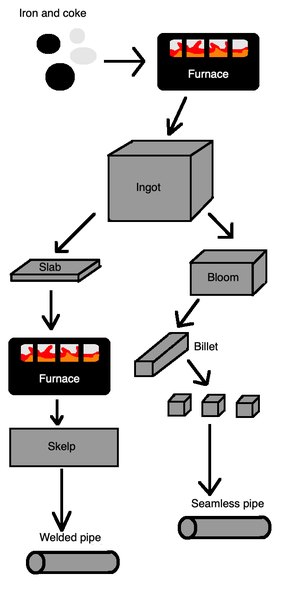

Bagaimana Tiub Keluli Dibuat?-Tiub Keluli

Bijih besi dan kok, bahan kaya karbon daripada arang batu yang dipanaskan, dicairkan menjadi bahan cecair dalam relau dan kemudian diletupkan dengan oksigen untuk menghasilkan keluli cair. Bahan ini disejukkan menjadi jongkong, tuangan besar keluli untuk menyimpan dan mengangkut bahan, yang dibentuk antara penggelek di bawah tekanan yang tinggi. Sesetengah jongkong disalurkan melalui penggelek keluli yang meregangkannya menjadi kepingan yang lebih nipis dan lebih panjang untuk menghasilkan bunga, perantaraan antara keluli dan besi. Ia juga digulung menjadi papak, kepingan keluli dengan keratan rentas segi empat tepat, melalui penggelek bertindan yang memotong papak ke dalam bentuk.Baca lagi -

Structural steel Pipe-ERW Steel Pipe

People have used pipes for thousands of years. Perhaps the first use was by ancient agriculturalists who diverted water from streams and rivers into their fields. Archeological evidence suggests that the Chinese used reed pipe for transporting water to desired locations as early as 2000 B.C. Clay tubes that were used by other ancient civilizations have been discovered. During the first century A.D. , the first lead pipes were constructed in Europe. In tropical countries, bamboo tubes were used to transport water. Colonial Americans used wood for a similar purpose. In 1652, the first waterworks was made in Boston using hollow logs.Baca lagi -

Methods of Manufacturing used in the Metal Pipe and Tubing Industries-ERW Steel Pipe

Also referred to as Electric Resistance Welded or ERW tubing, is produced when a strip of steel is passed through rollers to form the desired shape. The seam is then welded, forming a flash along the length on the inside and outside of the tube. The weld is then tested to ensure it meets the standard. Once the weld passes the testing process the tubing is formed to the exact size, straightened, and cut to length. ERW tube and pipe is available with the Weld flash in, flash removed or controlled (typically to .010”).Baca lagi -

BAGAIMANAKAH TUBUNG KELULI TAHAN KARAT DIHASILKAN?-Paip Keluli China

Raw material begins in the form of hot extruded seamless pipe, which is then cold reduced and processed through tube reducers in a long, straight form. Cold reducing is the most effective manufacturing method for longer lengths of tubing. Rolled pipes are cut to the required lengths and cleaned to remove debris in preparation for heat treatment, which is applied to remove any stresses that could occur during the formation or welding process.Various heat treatments can be used for tubing manufacturing, particularly annealing – this improves the structure of the metal and makes it more ductile for use in applications.Baca lagi -

Pembuatan Tiub Dikimpal-ERW Paip Keluli

Walaupun kedua-dua perkataan tiub dan paip sering digunakan secara bergantian, sebahagian besarnya kerana kedua-duanya berbentuk berongga, terdapat perbezaan penting antara kedua-duanya apabila menentukan keperluan tiub yang dikimpal berbanding lancar. Tiub diukur dengan diameter luar (OD) dan ketebalan dinding. Sebaliknya, paip diukur dengan diameter dalam (ID). Dari segi kefungsian, tiub biasanya digunakan dalam aplikasi struktur dan estetik manakala paip digunakan untuk mengangkut cecair, cecair dan gas.Baca lagi -

Bagaimanakah Tiub Dikimpal Dibuat?- Paip Keluli ERW

Manufacturing welded tubing on a large scale is a complex process that involves several steps.Metal coil is first selected using a thickness that will later match the thickness of the finished tube wall. The coil must also be wide enough so that the desired circumference and diameter can be achieved.The coil is fed through a series of dies and formed to shape. This brings two edges of the coil width towards each other until a tube is formed with one edge touching the other.A welding process is used to join these two edges together.Depending on the welded tube manufacturing process, the excess weld reinforcement may be removed at this time. The newly formed tubing may also undergo a heat-treatment process depending on the desired specifications.The tube is then cut to the desired length.Baca lagi