블로그

-

LSAW 강관 소개 - LSAW 강관 - ERW 파이프

Longitudinally Submerged Arc Welded Process FlowLSAW (Longitudinally Submerged Arc Welded Steel pipes) in leaflets plate as raw material, the steel plate in the mold or molding machine pressure (volume) into using double-sided submerged arc welding and flaring from production.The LSAW process of welded tube includes UOE and JCOEUOE LSAW pipe forming process:The three main forming processes of UOE LSAW steel pipe forming process include: steel plate pre-bending, U forming and O forming. Each process adopts a dedicated forming press to complete the three processes of pre-bending the edge of the steel plate, U forming and O forming in sequence to deform the steel plate into a circular tube.더 읽어보기 -

erw carbon steel pipe-a500 erw steel pipe tubes factories

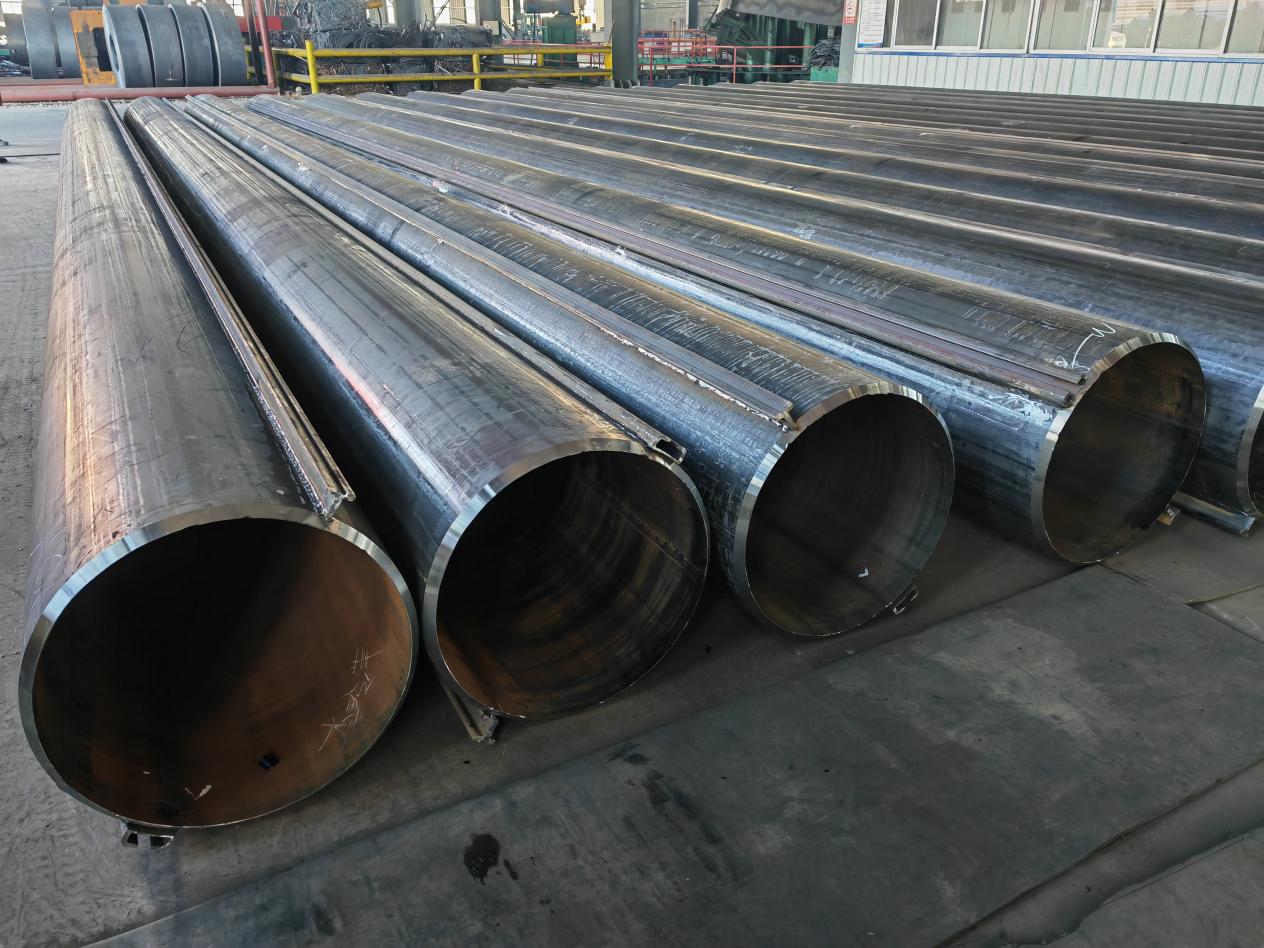

Longitudinally Submerged Arc Welding pipe(abbreviated as LSAW pipe). The Longitudinally Submerged Arc Welding (LSAW) is produced by using a single plate as a raw material, pressing (rolling) the steel plate into a pipe blank in a mold or a molding machine, and adopting double-sided submerged arc welding and expanding the diameter. The finished product has a wide range of specifications, and the weld has good toughness, plasticity, uniformity and compactness, and has the advantages of large pipe diameter, thick pipe wall, high pressure resistance, low temperature resistance and corrosion resistance.더 읽어보기 -

LSAW Pipe-lsaw 강관에 대해 이야기

종방향 침지형 아크 용접 파이프는 다양한 성형 방법에 따라 UOE, RBE, JCOE 강관으로 세분됩니다. 종방향 고주파 용접 강관은 상대적으로 공정이 간단하고 연속 생산이 빠른 특성을 가지며 토목 건설, 석유화학, 경공업 및 기타 분야에서 널리 사용됩니다. 주로 저압 유체를 운반하거나 다양한 엔지니어링 부품 및 경공업 제품으로 만들어지는 데 사용됩니다. 원료로 전단지 판의 LSAW (종방향 침지 아크 용접 강관), 금형의 강판 또는 성형 기계 압력 (부피)을 이중으로 사용 측면 서브머지드 아크 용접 및 생산 시 플레어링.더 읽어보기 -

LSAW Pipe-lsaw 강관에 대해 이야기

종방향 침지형 아크 용접 파이프는 다양한 성형 방법에 따라 UOE, RBE, JCOE 강관으로 세분됩니다. 종방향 고주파 용접 강관은 상대적으로 공정이 간단하고 연속 생산이 빠른 특성을 가지며 토목 건설, 석유화학, 경공업 및 기타 분야에서 널리 사용됩니다. 주로 저압 유체를 운반하거나 다양한 엔지니어링 부품 및 경공업 제품으로 만들어지는 데 사용됩니다. 원료로 전단지 판의 LSAW (종방향 침지 아크 용접 강관), 금형의 강판 또는 성형 기계 압력 (부피)을 이중으로 사용 측면 서브머지드 아크 용접 및 생산 시 플레어링.더 읽어보기 -

Longitudinal Submerged Arc Welding (LSAW) Processes-lsaw steel pipe-Stainless steel pipe

Steel pipes are long, hollow tubes that are used mainly to convey products from one location to another. They are produced mainly by two distinct manufacturing methods which result in either a welded pipe or seamless pipe. In both the manufacturing methods, raw steel is first cast into a more workable starting form (slabs, hot billet or flat strip). It is then made into a pipe by stretching the hot steel slab/billet out into a seamless pipe or forcing the edges of flat steel strip together and sealing them with a weld.더 읽어보기 -

Brief description and comparison of LSAW, SSAW and ERW pipes-lsaw steel pipe-ERW Steel Pipe

Brief description and comparison of LSAW, SSAW and ERW pipes-lsaw steel pipe SSAW pipes have greater residual stresses than LSAW pipes. The straight seam submerged arc welded pipe undergoes a uniform expansion process. The stress concentration phenomenon of SSAW pipe welds belongs to the severe category. SSAW pipes have a larger heat affected zone than LSAW pipes. The heat-affected zone is considered a weak point where failure may begin. The geometric accuracy of LSAW pipe is better than that of SSAW pipe, which is the key to ease of installation. LSAW pipe has approximately 60% fewer welds than SSAW pipe. ASTM A252 Piling Pipe application in buildings and retaining walls Brief description and comparison of LSAW, SSAW and ERW pipes Quality steel pipe is produced by three (3) manufacturing processes: Seamless, LSAW (Longitudinal Submerged Arc Welding) and ERW (Electric Resistance Welding). LSAW and ERW tubes are highly regarded for their wide range of applications. They are widely used in basic solutions and systems, marine construction, structural construction, and various applications in the fields of hydraulic engineering, petrochemical, chemical and power industries, agricultural irrigation, and urban construction. LSAW pipe comes in two types: longitudinal (single or double straight seam weld, DSAW) and helical (also known as SSAW, HSAW or SAWL). LSAW pipe differs from other LSAW pipes in that LSAW pipe has a seam weld on the inside and outside of the pipe, while the latter has only one seam weld on the outer surface, longitudinal or cross-section. SSAW and LSAW pipes are manufactured using a common manufacturing process known as the "JCOE and UOE Forming Process". The difference is that SSAW pipes are welded in a helical or helical position while LSAW pipes are welded longitudinally. The SSAW pipe is wound and welded by steel strip, its rotation direction is inclined to the axis or the center of the pipe, and the weld seam is helical. LSAW pipe is made by forming a steel plate into a cylinder and joining the ends together by straight-line welding. LSAW pipe diameters typically range from 16" to 60" (406mm to 1500mm). They have good high pressure and low temperature corrosion resistance. However, CSC Steel can supply pipe with diameters between 1 inch and 167 inches (21 mm and 4267 mm) and thicknesses between 3/32 inch and 4 inches (2.1 mm and 100 mm). ESC steel pipe is manufactured using LSAW in maximum diameter and thickness and is highly recommended for load bearing piles, composite wall piles and other applications. In the oil and gas industry, large diameter API 5L LSAW pipe is used to efficiently transport hydrocarbons over long distances. HSAW (Spiral Submerged Arc Welding) or SSAW pipe diameters typically range from 20" to 100" (406 mm to 2540 mm). One of the advantages of SSAW is the possibility of obtaining different diameters ERW pipe ERW Tube Forming SSAW pipe is made from standard size steel strip without cutting. On the other hand, the length of the spiral weld is much longer than the length of the pipe, the cost is higher, and it is prone to cracks, pores, slag inclusions, partial welding, etc. HSAW or spiral welded pipe is used in non-critical applications such as water distribution and not for oil and gas. CSC recommends SSAW pipes as main piles and dredging pipes for our composite walls.더 읽어보기 -

Seamless Pipe-Welded Steel Pipe

Steel pipes come in many forms and sizes. Seamless pipes are a non-welded option produced from hollowed-out steel billets. When it comes to welded steel pipes, there are three options: ERW, LSAW and SSAW.ERW pipes are made from electric resistance welded steel plates. LSAW pipes are made from longitudinally submerged arc welded steel plates. SSAW pipes are made from spiral submerged arc welded steel plates.Steel pipes are typically used in the oil and gas industry for exploration and extraction (upstream), the transmission of fluids like oil, gas and slurries (midstream) and oil refinement into derivative products (downstream). They are also used for agricultural irrigation, urban construction and more.Let’s take a closer look at each type of pipe, comparing their differences and how to make an order with the right description.더 읽어보기 -

What is the difference between SSAW and LSAW pipes?-lsaw steel pipe-ERW Steel Pipe

SSAW (Spiral Submerged Arc Welding) and LSAW (Longitudinal Submerged Arc Welding) are two different methods used for manufacturing welded steel pipes. Here's a comparison of the main differences between SSAW and LSAW pipes:Formation process:SSAW Pipe: The spiral welding process involves forming the steel strip into a spiral shape and then welding the edges using the submerged arc welding method.LSAW Pipe: The longitudinal welding process involves forming a straight, cylindrical pipe from a single steel plate or coil and then welding along the length of the pipe using the submerged arc welding technique.더 읽어보기 -

LSAW large-diameter pipe plants-lsaw steel pipe

In LSAW pipe mills, processing is done by cold forming of heavy carbon steel plates. Among the available forming processes, SMS group focuses on the JCO technology. We supply the equipment for all important process steps from plate preparation to forming, welding, testing, and finishing. Including not only the core machines, but also all the upstream and downstream process steps required for the production of large-diameter pipes.Our plants stand for high product quality at medium to high output, flexible and cost-effective processes, precise dimensions, and close pipe tolerances.더 읽어보기