ブログ

-

シームレスステンレス鋼管の製造方法 - ERW鋼管

衛生管継手やバルブについて話すとき、「チューブ」と「配管」という用語はよく同じ意味で使われますが、違いがあります。チューブは主に美観と構造目的で使用されるため、外径と壁の厚さで測定されます。一方、パイプは液体とガスの輸送に特化しているため、内径で測定されます。続きを読む -

鋼管はどのように製造されるのか? - ERW鋼管

鋼管の製造工程の最初のステップは、原材料の選択です。ご想像のとおり、この工程で使用される主な材料は鋼です。鋼は鉄と炭素から作られた合金で、鋼に含まれる炭素含有量が完成品の強度と耐久性の大きな決定要因となります。製品の特定の特性を向上させるために、ニッケル、クロム、モリブデンなどの他の材料が含まれる場合もあります。続きを読む -

ステンレス鋼管およびチューブの製造プロセス - 溶接鋼管

プロセスを開始するには、まず圧延と溶接の段階を経る必要があります。この段階で、ステンレス鋼はチェック プロセスにかけられ、端が切断されます。ステンレス鋼は、圧延機で押し込まれ、必要な管状サイズに成形されます。圧延機で押し込まれて回転された後、端は TIG と呼ばれる加熱プロセスで溶接されます。TIG 溶接プロセスでは、電極が組み込まれた電気アークを使用して、圧延された金属を接合します。続きを読む -

Understanding the Manufacturing Process of Steel Pipes- China Steel Pipe

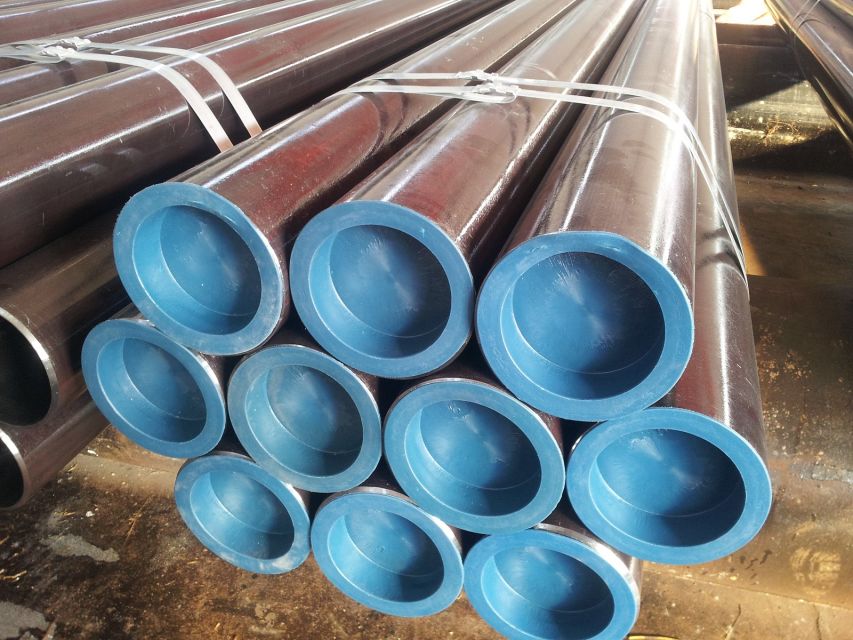

Steel pipes, also known as steel tubes, are hollow cylindrical constructions manufactured from steel, a strong and flexible material noted for its durability and resistance to corrosion. There are different kinds of steel pipes available, including seamless pipes and welded pipes. Seamless pipes are manufactured without any welding joints, while welded pipes are constructed by joining two pieces of steel using welding techniques.続きを読む -

Manufacturing method of seamless pipe-ERW Steel Pipe

Hot-rolled seamless pipes are generally produced on automatic pipe rolling units. After checking and removing surface defects, the solid tube blank is cut into the required length, centered on the perforated end face of the tube blank, then sent to the heating furnace for heating, and pierced on the piercing machine. Spin and advance the solid blank inside the process of piercing holes under the influence with the roller as well as the end. Then the solid blank is hollow finally, which is called gross pipe. Send to the automatic pipe rolling machine to continue rolling. Finally, the wall thickness is adjusted by the equalizing machine, and the size is sized by the sizing machine to meet the specification requirements. It is a more advanced method to produce hot-rolled seamless steel pipes by using continuous rolling mills.続きを読む -

Stainless Steel Pipe and Tube Manufacturing Process-ERW Steel Pipe

In the nineteenth century, rolling mill technology was the only technique used to manufacture stainless tubes and pipes for industrial purpose. This rolling technique involved long procedures. The rolled strips of sheet were formed into a circular cross section with the help of funnel rolls. The lap welding was then done on these rolled strips through the forge welding process.Thankfully with the advent of development and technology, various processes came into existence for the manufacturing of stainless tubes and pipes in India. Now-a-days, stainless steel pipes and tubes are manufactured with continuous tube mill using multitorch tungsten Inert gas. The filler metal or forge welding process is not used in this technique.続きを読む -

The First Methods for Producing Steel Pipe -Welded Steel Pipe

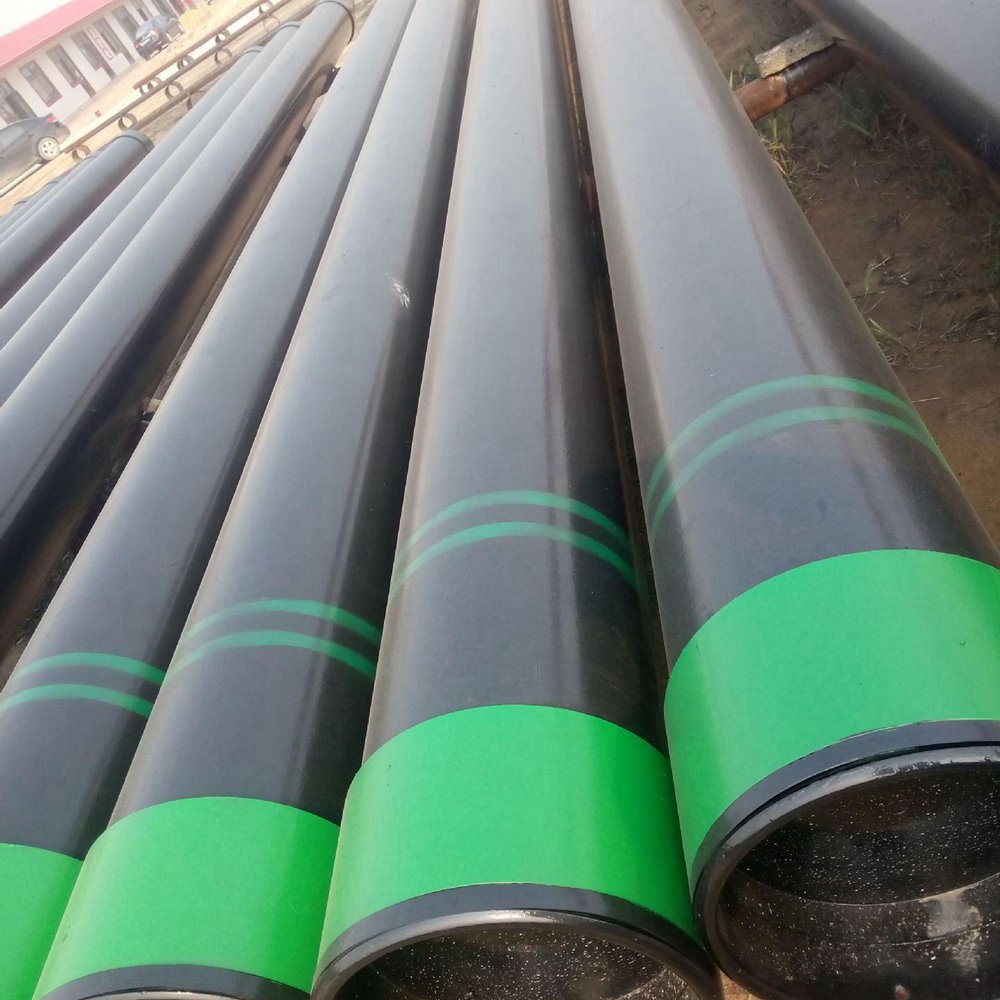

Steel pipes are long, hollow tubes that are used for a variety of purposes. They are produced by two distinct methods which result in either a welded or seamless pipe. In both methods, raw steel is first cast into a more workable starting form. It is then made into a pipe by stretching the steel out into a seamless tube or forcing the edges together and sealing them with a weld. The first methods for producing steel pipe were introduced in the early 1800s, and they have steadily evolved into the modern processes we use today. Each year, millions of tons of steel pipe are produced. Its versatility makes it the most often used product produced by the steel industry.続きを読む -

What are the production processes for LSAW steel pipes?-ERW Steel Pipe

The advent of rolling mill technology and its development during the first half of the nineteenth century also heralded in the industrial manufacture of tube and pipe. Initially, rolled strips of sheet were formed into a circular cross section by funnel arrangements or rolls, and then butt or lap welded in the same heat (forge welding process).Toward the end of the century, various processes became available for the manufacture of seamless tube and pipe, with production volumes rapidly increasing over a relatively short period. In spite of the application of other welding processes, the ongoing development and further improvement of the seamless techniques led to welded tube being almost completely pushed out of the market, with the result that seamless tube and pipe dominated until the Second World War.During the subsequent period, the results of research into welding technology led to an upturn in the fortunes of the welded tube, with burgeoning development work ensuing and wide propagation of numerous tube welding processes. Currently, around two thirds of steel tube production in the world are accounted for by welding processes. Of this figure, however, about one quarter takes the form of so-called large-diameter line pipe in size ranges outside those which are economically viable in seamless tube and pipe manufacturing.続きを読む -

The Types Of Steel Pipes-Stainless steel pipe

A steel pipe is steel with a hollow section and its length is much greater than its diameter or circumference. There are many steel grades and specifications of steel pipe products, and their performance requirements are also various. All these should be differentiated according to user requirements or changes in working conditions. Generally, steel pipe products are classified according to cross-sectional shape, production method, pipe material, connection method, plating characteristics, and use.続きを読む