Jan . 16, 2024 14:45 Retour à la liste

Comparison of Hot Rolled & Cold Rolled SS Steel Pipe-ERW Steel Pipe

How Is Seamless Stainless Steel Pipe Made - Seamless Stainless Steel Pipe

TUBE À PRESSION

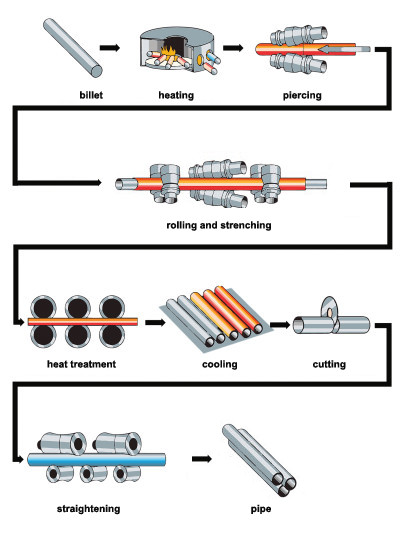

With the above basic process, the billets become pipes, then according to different requirements, the pipes would then receive heat treatment, cooling, straightening and other tests. Generally, the common manufacturing process of seamless stainless steel tube is as follows:

Comparison of Hot Rolled & Cold Rolled SS Steel Pipe

While seamless steel pipes can be formed into hot and cold rolled technique. How to distinguish hot and cold rolled seamless stainless steel pipe?

| Hot rolled | Cold rolled |

|---|---|

| Larger diameter | Smaller diameter |

| Lower accuracy | Higher accuracy |

| Cheaper | More expensive |

| Technique process: 1. heating 2. perforation 3. extrusion 4. sizing block 5. hot rolling 6. cooling 7. heat straightening 8. Hydraulic test (or flaw detection) 9. marking 10. storage |

Technique process: 1. heating 2. perforation 3. annealing 4. pickling→oil coating 5. cold rolling 6. heat treatment 7. straightening 8. Hydraulic test (or flaw detection) 9. marking 10. storage |

1.Advantages of hot rolled process

Hot rolled seamless steel pipe can damage the casting structure of the steel ingot, refine the crystal grains of the steel, and eliminate the defects of the microstructure. In this way, the steel organization is compacting and the mechanical properties would be improved.

This improvement is reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent; bubbles, cracks and looseness formed during casting can also be welded under high temperature and pressure.

2.Advantages of cold rolled process

Forming fast, high output and no damage to the coating, cold rolled seamless stainless steel tubes can be made into a variety of cross sectional forms to meet the needs of the use of conditions.

In addition, cold rolled process can cause great plastic deformation, so as to improve the yield of the steel point.

-

Carbon Steel Tube Pressure Rating-steel pie

NouvellesJan.16,2024

-

Stainless steel-Electric Resistance Welded (ERW) Pipe-Welded (ERW) Pipe

NouvellesJan.16,2024

-

High Frequency Electric Weld (ERW) Line Pipe and Standard Products-ERW Steel Pipe

NouvellesJan.16,2024

-

How Is Steel Tubing Made?-Steel Tubing

NouvellesJan.16,2024

-

Structural steel Pipe-ERW Steel Pipe

NouvellesJan.16,2024

-

Methods of Manufacturing used in the Metal Pipe and Tubing Industries-ERW Steel Pipe

NouvellesJan.16,2024