博客

-

无缝管-ERW钢管的制造方法

无缝管的生产方法大致分为斜轧法(门内斯曼法)和挤压法。前一种方法是先用斜轧辊将管坯穿孔,然后用轧机将其延伸。这种方法生产速度快,但对管坯的机械加工性要求较高,主要适用于碳素钢和低合金钢管的生产。后一种方法是先用穿孔机将管坯或钢锭穿孔,然后用挤压机将其挤压成钢管。这种方法的效率比斜轧法低,适用于生产高强度合金钢管。斜轧法和挤压法都必须先将管坯或钢锭加热,生产出来的钢管称为热轧管。用热加工方法生产的钢管有时可以根据需要进行冷加工。阅读更多 -

Comparison of Hot Rolled & Cold Rolled SS Steel Pipe-ERW Steel Pipe

Hot rolled seamless steel pipe can damage the casting structure of the steel ingot, refine the crystal grains of the steel, and eliminate the defects of the microstructure. In this way, the steel organization is compacting and the mechanical properties would be improved.This improvement is reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent; bubbles, cracks and looseness formed during casting can also be welded under high temperature and pressure.阅读更多 -

不锈钢管-a500 erw钢管工厂

一般无缝钢管的生产工艺可分为冷拔和热轧两种,冷轧无缝钢管的生产工艺一般比热轧复杂,在定径试验时,如果表面没有反应裂纹,就必须用切割机切割管子,切成一米左右长度的毛坯,然后进入退火工序,退火需要用酸性液体进行酸洗,酸洗的时候要注意表面是否有大量的起泡现象,如果有大量的起泡现象,说明钢管的质量不符合相应的标准,在外观上,冷轧无缝钢管比热轧无缝钢管要短,冷轧无缝钢管的壁厚一般比热轧无缝钢管要小,但是表面看上去比厚壁无缝钢管要光亮很多,粗糙度要高,没有太多的毛刺。阅读更多 -

探索焊管制作工艺-焊接钢管

通常使用四种不同的焊接工艺来制造管材。由于这些焊缝中没有填充金属,因此焊缝至少与母材一样坚固。高频 (HF) 焊接。如今,大多数低碳钢和铝管都使用 HF 焊机进行焊接,如果管材用于装饰用途,这种焊机也适用于 400 系列不锈钢,甚至 300 系列。近 95% 的 HF 焊机都是固态的,使用晶体管产生交变频率电流。已经开展了研究,以焊接直径小于 1/4 英寸的产品,并扩展焊机在高线速下对 300 不锈钢进行压力质量焊接的能力。阅读更多 -

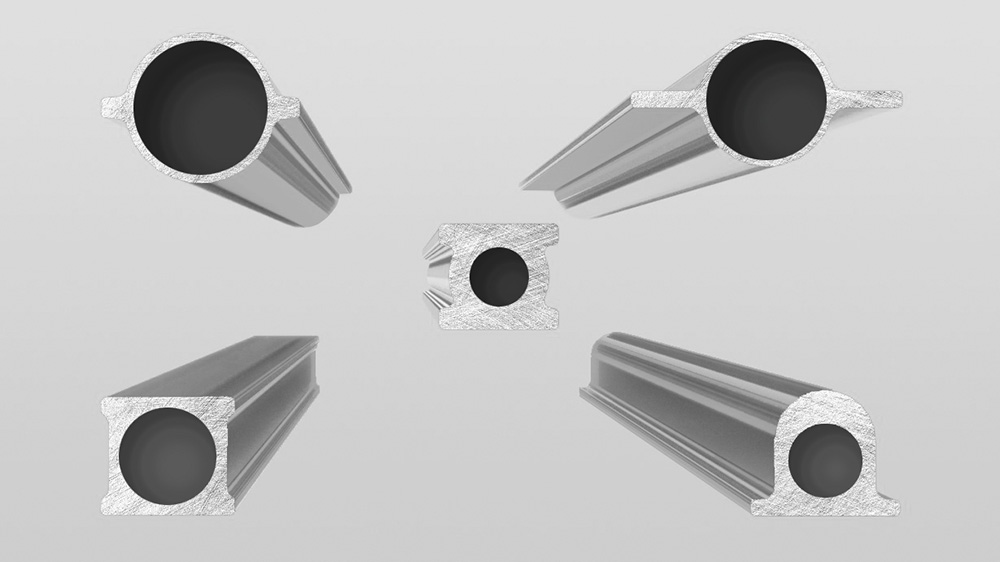

Methods Of Manufacturing Steel Tubes And Pipes-ERW Steel Pipe

Billet-Heating-Mannesmann piercer-Elongator-Plug mill-Reeler-Reheating-SizerWhen a seamless pipe is made by rolling, the rolling method involves piercing the material while it is being rolled, and is suitable for mass production. The figure shows the manufacturing process used in the Mannesmann plug mill, which is a typical rolling process. The Mannesmann-type piercer reduces the material by rolls that are inclined obliquely to each other. When the round billet is rotated while being compressed in the diametric direction, the central part of the billet becomes loose, which makes it easy to pierce a hole through the center. This is called the Mannesmann effect. The pierced portion is expanded by the elongator, and the wall thickness is then thinned and elongated by the pug mill. The internal and external surfaces are smoothed by the reeler, and the final dimensional adjustments are made by the sizer.阅读更多 -

热挤压无缝钢管-无缝钢管-erw 管

通过热挤压获得的无缝钢管是一种制造工艺的结果,其中作用力是压缩。在热挤压过程中,钢坯被推过所谓的“通道灯”,这些灯被成型并排列在称为基体的特殊工具上,以获得所需的形状。这种加工在高温下进行,以减少必要的力,并且更容易对材料进行操作,如果在室温下加工,这些材料的性质不会特别具有延展性。阅读更多 -

热挤压无缝钢管-不锈钢管

通过热挤压获得的无缝钢管是一种制造工艺的结果,其中作用力是压缩。在热挤压过程中,钢坯被推过所谓的“通道灯”,这些灯被成型并排列在称为基体的特殊工具上,以获得所需的形状。这种加工在高温下进行,以减少必要的力,并且更容易对材料进行操作,如果在室温下加工,这些材料的性质不会特别具有延展性。阅读更多 -

Seamless steel pipes-ERW Steel Pipe

Seamless steel pipes are produced by piercing a solid billet of steel to form a hollow tube. The billet is heated to a temperature that allows it to be easily pierced by a piercing mill. The mill contains a mandrel, which is a cylindrical tool that supports the inside of the tube during the piercing process.Once the billet is pierced, it is rolled and stretched to achieve the desired shape and size of the tube. This process is known as the extrusion process. The extrusion process can produce seamless pipes of various sizes and thicknesses, making them suitable for a range of applications.The main advantage of seamless pipes is that they have a smooth surface finish, which is essential for industries such as water supply, where cleanliness is crucial. Seamless pipes are also stronger and more durable than welded pipes, making them suitable for applications where high pressure and high temperatures are involved, such as in the oil and gas industry.阅读更多 -

how are steel tubes made-Welded Steel Pipe

Steel tube (and Steel Pipe) has evolved over history. Specifically, metal tube has been around since around 3000 BC. In fact, Egyptians made the first metal pipe from copper.As Early as 2500 BC Chinese used bamboo pipe as a way to transport gasAs early as 2500 BC, Chinese used bamboo pipe as a way to transport natural gas to light Peking, their capital. Rome and Persia created aqueducts to bring water to city centers for bathing, washing and drinking.Furthermore, pipe (or tubing) is made with many different materials and methods. Hollowed stone, fired clay, bamboo, palm, redwood, lead, bronze, copper, and rubber are just some of the materials that makeup tubing.In the mid-1800’s the modern steel industry was bolstered with the Bessemer process. The Bessemer process represented the first inexpensive method for mass production of steel pipe. Subsequently, seamless tube was born in 1895. Quickly followed by manufacturing of auto, bicycle, and machinery for oil production which began in full force.阅读更多