DE:4"-56"

Espessura da parede:3mm-45mm

Comprimento:3m-14m

Spadrão: ASTM A53/GB 3091/API 5L/ASTMA252/ASTM A500/ASTMA671/ASTMA672/ASTMA500/ASTM A572/EN10219/EN10210/AS1163

Material:Grau A Grau B Q235A Q235C Q235B、16Mn 20# Q355 L245 L290 X42 X46 X52 X56 X60 X70 X80 C350 C350L0 CC60 CC65 S355J0H S355J2H S275JOH S275JR ASTM A36

Tipo:Tubo ERW ou tubo HFW, tubo LSAW, tubo SSAW

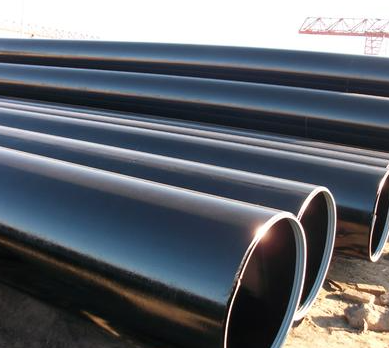

Welded Steel Pipe Advantages

The production process of straight seam welded pipe is simple, the production efficiency is high, the welded steel pipe cost is low, and the development is rapid. The strength of the spiral welded pipe is generally higher than that of the straight seam welded pipe, and the welded pipe with a larger diameter can be produced with a narrower billet, and different welded steel pipe dimensions can be produced with the same width billet. But compared with the straight seam pipe of the same length, the weld length is increased by 30~100%, and the production speed is lower.

Welded Steel Pipe Applications

Carbon welded steel pipes are widely used in water projects, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, and urban construction.

Usado para transporte de líquidos: abastecimento de água e drenagem. Para transporte de gás: gás, vapor, gás liquefeito de petróleo.

Para fins estruturais: como tubos de estacas e pontes; tubos para cais, estradas e estruturas de edifícios, etc.

Huayang as one of the biggest carbon steel pipe manufacturer, we have 12 production lines of carbon steel ERW pipes,3 production lines of the LSAW pipe,we have also about 40000tons stock in order to provide the convenient.Yearly output about 1700000tons.

What Is Difference Between Seamless And Welded Pipe

The main difference between seamless and welded pipes lies in their manufacturing process and the structural integrity of the final product. Here are the key distinctions between seamless and welded pipes:

Manufacturing Process:

Seamless Pipes: Seamless steel tubes are manufactured through a process that involves piercing a solid billet or ingot to create a hollow tube. The tube is then elongated to the desired size using a mandrel mill or a rotary piercer. This process results in a seamless and uniform structure without any welding joints.

Welded Pipes: Welded pipes are manufactured by welding two or more pieces of steel together to form a tube. There are various welding methods used, such as electric resistance welding (ERW), submerged arc welding (SAW), and seamless pipe welding (SAWH). Welded pipes may have a longitudinal or spiral seam, depending on the manufacturing method.

Seam Presence:

Seamless Pipes: As the name suggests, seamless pipes do not have a welded seam. They are a continuous structure, which can provide better structural integrity and strength.

Welded Pipes: Welded pipes have a visible seam that runs along their length. The presence of a seam may affect the overall strength and integrity of the pipe, depending on the welding method used.

Strength and Performance:

Seamless Pipes: Seamless pipes are generally considered stronger and more reliable because they lack the weak points associated with welding. They are often preferred for applications where high pressure, high temperature, or corrosive environments are factors.

Welded Pipes: While welded pipes are suitable for many applications, they may have slightly lower strength compared to seamless pipes due to the presence of the welded seam. However, advancements in welding techniques have improved the performance of welded pipes in various scenarios.

Cost and Availability:

Seamless Pipes: The seamless pipe manufacturing process is often more complex and requires higher initial costs. As a result, seamless pipes are usually more expensive than welded pipes. Additionally, the availability of seamless pipes in larger sizes may be limited.

Welded Pipes: Welded pipes are generally more cost-effective and readily available, making them a common choice for less critical applications.

Why Choose Huayang Welded Steel Pipe Manufacturers

When it comes to sourcing welded steel pipes, selecting the right manufacturer is crucial for the success and longevity of your projects. Huayang Welded Steel Pipe Manufacturer stands out as a trusted and reliable supplier in the industry, offering a range of benefits that make them a preferred choice for discerning customers.

Quality Assurance:

Huayang Welded Steel Pipe Manufacturer places a strong emphasis on quality assurance throughout the manufacturing process. Adhering to rigorous standards, their welded steel pipe for sale meet or exceed industry specifications, ensuring durability and reliability in diverse applications. This commitment to quality gives customers confidence in the performance of the welded steel pipes they purchase.

Competitive Pricing:

Understanding the significance of cost-effectiveness in any project, Huayang offers competitive welded steel pipe prices without compromising on quality. By optimizing their production processes and maintaining efficient operations, they deliver value to customers, making high-quality welded steel pipes accessible for various applications.

Diverse Product Range:

Huayang welded steel pipe factory provides a diverse range of welded steel tubes, catering to different specifications and requirements. Whether you need pipes for industrial, construction, or infrastructure projects, they offer a comprehensive selection in various sizes and wall thicknesses. This versatility ensures that customers can find the perfect solution for their specific needs.

Transparency in Specifications:

Customers benefit from the transparency provided by Huayang regarding welded steel pipe specifications. The manufacturer provides detailed information about their products, empowering customers to make informed decisions based on their project requirements. This commitment to transparency fosters trust and helps customers choose the right pipes for their applications.

Reliable After-Sales Support:

Huayang welded steel pipe supplier is known for its commitment to customer satisfaction beyond the point of sale. They provide reliable after-sales support, addressing any queries or concerns promptly. This customer-centric approach enhances the overall experience of working with Huayang, fostering long-term relationships with clients.