Jul . 27, 2024 19:38 Back to list

Top Manufacturers of High-Quality API 5L X70 Steel Pipes for Industrial Applications Worldwide

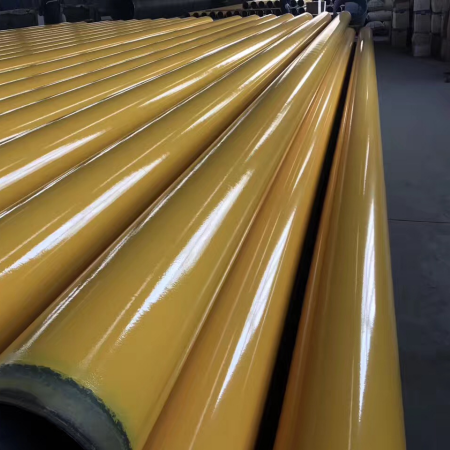

High-Quality API 5L X70 Steel Pipe Manufacturers An Overview

In the realm of modern construction and pipeline infrastructure, the demand for high-quality steel pipes is paramount. Among the various steel pipe standards available, the API 5L X70 specification stands out due to its exceptional performance characteristics and suitability for high-pressure environments. The manufacturers producing these pipes play a critical role in ensuring the integrity and reliability of the pipelines that transport oil, natural gas, and other vital resources.

Understanding API 5L X70 Steel Pipes

API 5L is an American Petroleum Institute specification that covers line pipe made from different grades of steel. The X70 grade, in particular, is designed for high-strength applications and is often used in pipelines that must withstand high pressures and harsh conditions. The designation X70 signifies a minimum yield strength of 70,000 psi, making it one of the strongest options available in pipeline construction.

The X70 pipes are typically produced using advanced manufacturing techniques, ensuring that they meet stringent quality standards. These pipes are known for their excellent mechanical properties, including high tensile strength, good weldability, and resistance to external stress. These qualities make them a preferred choice for companies operating in the oil and gas sector.

Key Qualities of High-Quality Manufacturers

When seeking high-quality API 5L X70 steel pipe manufacturers, several factors come into play

high quality api 5l x70 steel pipe manufacturers

1. Certifications and Compliance Reputable manufacturers adhere to international standards and possess the necessary certifications. It is essential to verify that the manufacturer complies with API specifications, as this ensures that the steel pipes produced meet the required safety and performance criteria.

2. Production Techniques High-quality manufacturers invest in modern production technologies, such as Electric Resistance Welding (ERW) and Seamless pipe production methods. These techniques enhance the structural integrity and overall quality of the pipes.

3. Quality Control A rigorous quality control system is vital for ensuring that every batch of steel pipes meets the necessary standards. This includes testing for mechanical properties, dimensional accuracy, and resistance to corrosion. Manufacturers often employ non-destructive testing methods to confirm the integrity of the pipes.

4. Material Sourcing The quality of the raw materials used directly impacts the finished product. Top manufacturers source high-grade steel from reputable suppliers, ensuring that the raw materials meet the stringent requirements for the production of X70 pipes.

5. Customer Service and Support Reliable manufacturers prioritize customer satisfaction by offering comprehensive support, from technical assistance to after-sales service. A manufacturer’s ability to understand and meet specific customer requirements often distinguishes the best from the rest.

Conclusion

The demand for API 5L X70 steel pipes is set to rise as global energy needs grow. Selecting a high-quality manufacturer is crucial for ensuring that these pipes can withstand the challenges of extreme environments and high-pressure applications. By focusing on manufacturers that emphasize compliance, advanced production techniques, strict quality control, and superior customer service, companies can ensure they are investing in products that deliver safety and reliability in their pipeline projects. The strength of these pipes is not just a matter of measurement; it’s an assurance of the longevity and safety of the resources they transport, making the choice of manufacturer a significant consideration in the energy sector.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024