Jul . 27, 2024 19:31 Back to list

Top Exporters of ERW EN 10255 Galvanized Steel Pipes for Global Markets Today

ERW and Galvanized Steel Pipe Exporters A Comprehensive Overview

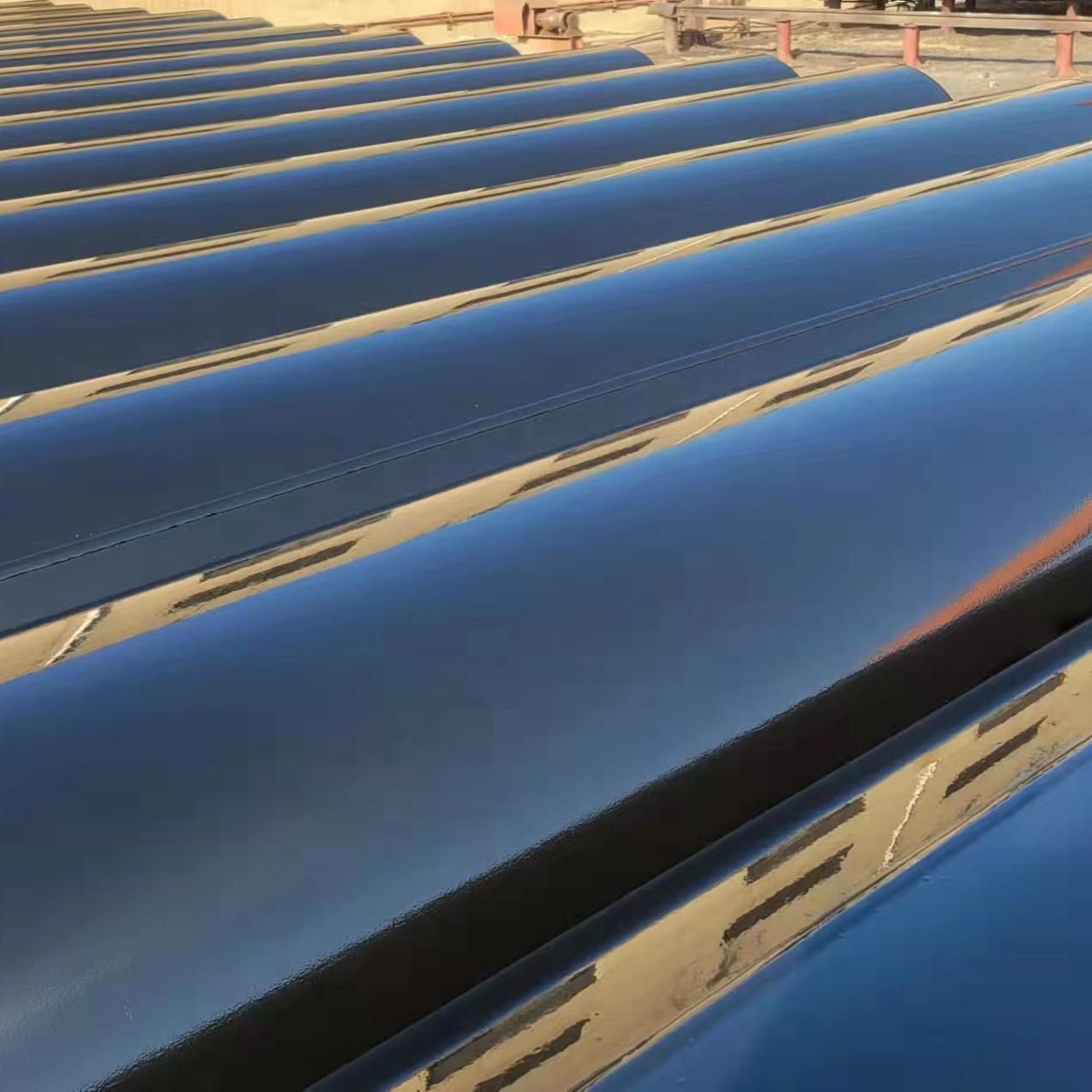

Electric Resistance Welded (ERW) steel pipes, particularly those made from galvanized steel, have become essential in various industries around the globe. These pipes are manufactured using a specific welding technique that offers significant advantages, such as durability, cost-effectiveness, and versatility. This article delves into the significance of ERW galvanized steel pipes and the role of exporters in this market.

What is ERW Galvanized Steel Pipe?

ERW pipes are produced by rolling metal sheets and welding them along the seam. The process involves passing an electric current through the edges of the steel sheets, which creates heat, leading to a solid bond once they are pressed together. When these pipes are galvanized, a layer of zinc is applied to their surface to prevent corrosion. This galvanization enhances the pipes' durability, making them suitable for use in harsh environmental conditions.

Applications of ERW Galvanized Steel Pipes

Due to their properties, ERW galvanized steel pipes find applications in various sectors, including

1. Construction Used extensively in structural applications, such as scaffolding, support beams, and frameworks. 2. Water Supply Commonly employed in municipal water systems, irrigation projects, and plumbing, owing to their resistance to corrosion. 3. Oil and Gas Suitable for transporting oil and natural gas, these pipes can withstand high pressures and harsh conditions.

4. Electrical These pipes are also utilized as conduits for electrical wiring, providing both structural support and protection.

5. Automotive In the automotive industry, ERW pipes are used for exhaust systems and other applications requiring resilience and strength.

The Role of Exporters

erw en 10255 galvanized steel pipe exporters

The market for ERW galvanized steel pipes is expanding globally, leading to an increase in the number of exporters in this sector. These exporters play a crucial role by bridging the gap between manufacturers and international markets. Their responsibilities include

- Quality Assurance Exporters ensure that the products meet international standards and specifications, as the quality of steel pipes is paramount for safety and performance.

- Market Accessibility They provide access to markets that might not be easily reachable for manufacturers, thereby broadening their customer base.

- Custom Logistics Handling shipping, customs clearance, and local regulations, exporters facilitate smooth transactions across borders.

- Competitive Pricing By sourcing pipes from various manufacturers, exporters can offer competitive pricing, benefiting both buyers and sellers.

- Customer Support They provide support services, including technical assistance and after-sales service, enhancing the overall customer experience.

Challenges Faced by Exporters

While the market for ERW galvanized steel pipes is growing, exporters face several challenges, such as fluctuating raw material costs, trade regulations, and competition from local manufacturers. Additionally, ensuring compliance with environmental regulations and sustainability practices is becoming increasingly important in today’s market.

Conclusion

In conclusion, ERW galvanized steel pipes play a pivotal role in multiple industries, reflecting their importance in modern construction, infrastructure, and utility services. Exporters are essential to this market, facilitating the distribution of high-quality products worldwide. As demand for these pipes continues to grow, the role of exporters will become even more critical in ensuring that quality standards are met, prices remain competitive, and markets are effectively accessed. Embracing both technological advancements and sustainable practices will be key to success in this dynamic industry.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024