Jul . 29, 2024 21:36 Back to list

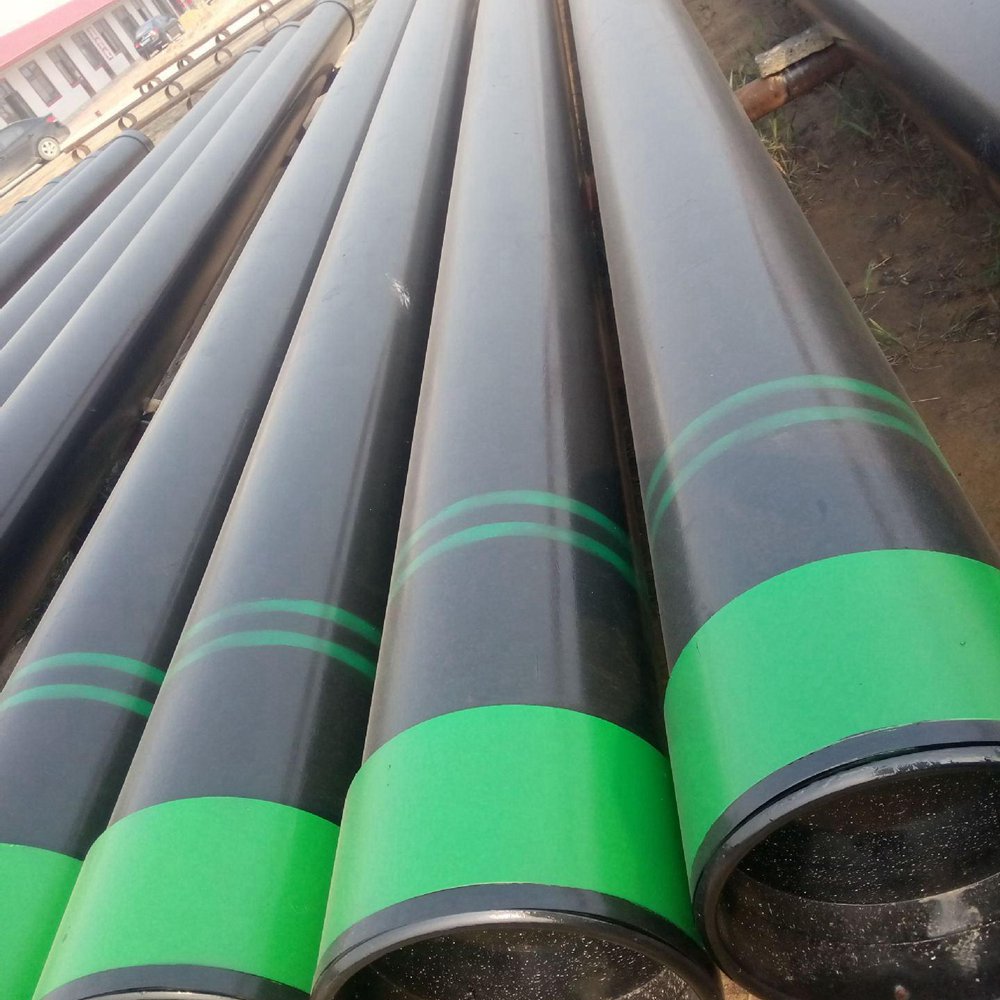

Reliable Supplier of Premium Quality Steel Pipe for Butt Welding Applications in Various Industries

High-Quality Steel Pipe Butt Welding Suppliers Ensuring Reliability and Efficiency

In the realms of construction, manufacturing, and various industrial applications, the integrity of welding processes is paramount. Butt welding, in particular, is a crucial technique for joining steel pipes. As industries strive for improved performance and safety standards, the demand for high-quality steel pipe butt welding suppliers has surged. This article explores the significance of these suppliers, the qualities that set them apart, and the impact they have on overall project success.

Understanding Butt Welding

Butt welding involves aligning two pieces of steel pipe end-to-end and applying heat to fuse them together. The process can be executed using various methods, including electric resistance welding and gas tungsten arc welding. The choice of method often depends on the specific application and the materials involved. Butt welding is lauded for its strength and durability, making it a preferred choice in high-pressure and high-temperature applications.

The Importance of High-Quality Suppliers

High-quality steel pipe butt welding suppliers play a pivotal role in ensuring that welding materials meet stringent industry standards. These suppliers are responsible for providing pipes that are not only robust but also have consistent mechanical properties. Choosing a reputable supplier ensures that the pipes are made from high-grade steel, undergo rigorous testing, and comply with industry-specific certifications, such as ASTM, ISO, and ASME.

Key Qualities of a Reliable Supplier

1. Material Quality A top-tier supplier utilizes high-quality raw materials, ensuring that the final product can withstand various pressures and temperatures. The durability of the pipes is essential in preventing failures that could lead to catastrophic incidents.

high quality steel pipe butt welding supplier

2. Advanced Manufacturing Processes The best suppliers invest in state-of-the-art manufacturing technology. This includes automated welding machines and precise quality control measures that enhance the consistency and reliability of the pipes.

3. Skilled Workforce A knowledgeable and skilled workforce is invaluable. Suppliers should employ experienced welders and technicians who are adept in the latest welding techniques and safety standards.

4. Custom Solutions Different projects may require unique specifications. High-quality suppliers offer customization options to meet specific client needs, whether it's for dimensions, wall thickness, or specific coatings.

5. Comprehensive Support Beyond providing materials, reputable suppliers often offer comprehensive support services, including consultation on welding techniques, project management assistance, and after-sales support.

Impact on Project Success

The choice of a steel pipe butt welding supplier can significantly influence the outcome of a project. Projects that utilize high-quality materials and workmanship are more likely to meet deadlines, stay within budget, and achieve operational efficiency. In industries such as oil and gas, construction, and manufacturing, where safety is a top priority, relying on credible suppliers becomes non-negotiable.

Moreover, a dependable supplier helps mitigate risks associated with weld failures, which can lead to financial losses and reputational damage. Investing in quality means fewer inspections, rework, and potential downtimes, translating to a more streamlined operation.

In conclusion, high-quality steel pipe butt welding suppliers are integral to ensuring that welding projects meet the rigorous demands of modern industries. By prioritizing material quality, advanced manufacturing processes, skilled labor, and customer support, these suppliers not only deliver superior products but also contribute to the safety and success of various projects. As industries continue to evolve, the role of reputable welding suppliers will remain vital in paving the way for innovation and reliability in the manufacturing and construction sectors.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024