Jul . 26, 2024 00:40 Back to list

High-Quality Carbon Steel Pipe Applications and Benefits in Modern Construction Projects

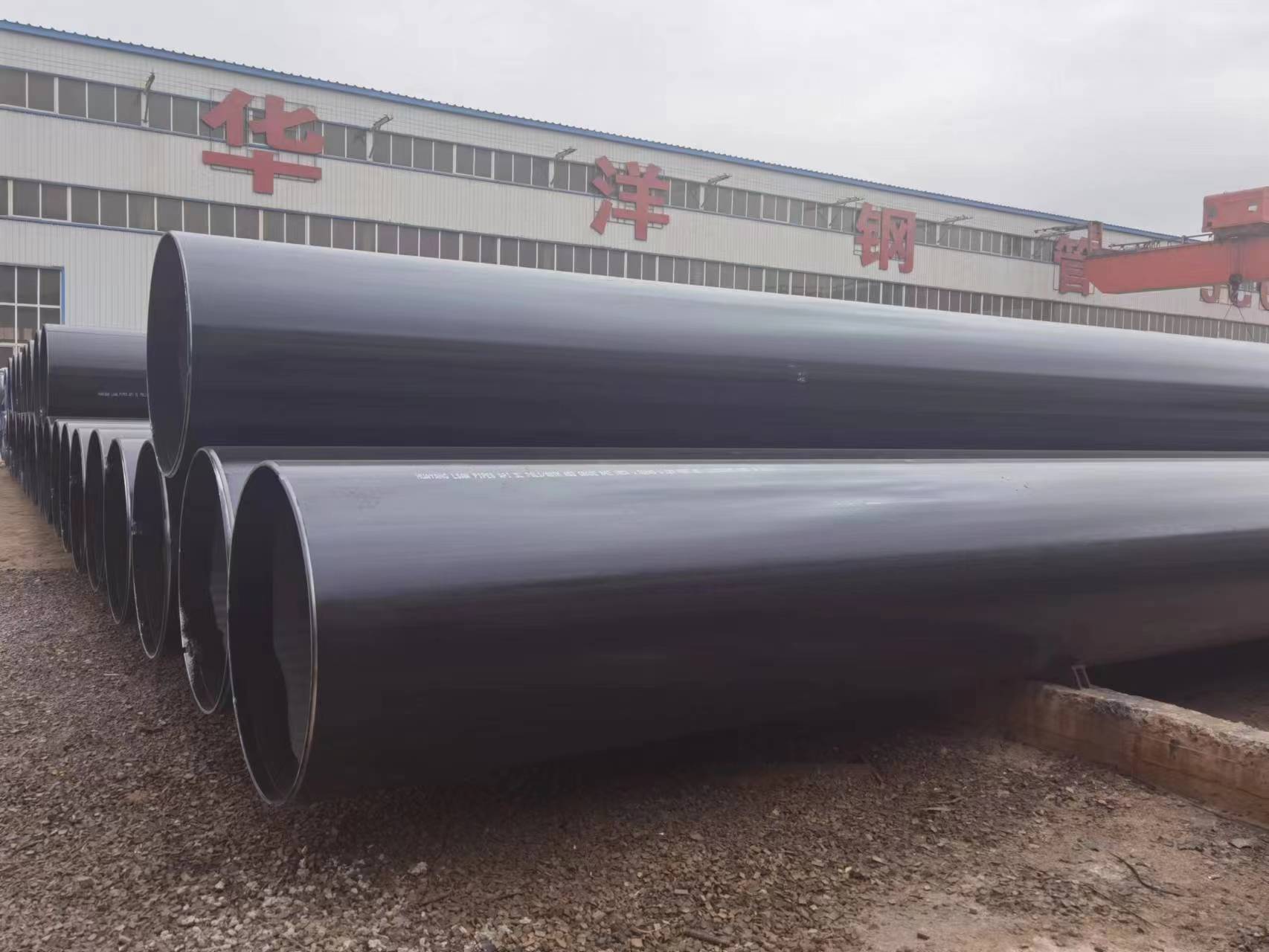

High-Quality Carbon Steel Pipe Construction An Overview

When it comes to construction, particularly in industrial and infrastructure projects, the choice of materials plays a crucial role in ensuring durability, safety, and overall performance. One of the most widely used materials in this context is high-quality carbon steel pipes. These pipes are favored for their strength, flexibility, and resistance to various environmental conditions, making them ideal for a range of applications, including oil and gas transportation, water supply systems, and structural support.

Properties of High-Quality Carbon Steel

High-quality carbon steel is an alloy made primarily of iron and carbon. The carbon content can vary—from low carbon at around 0.05% to high carbon at about 2%—which influences its properties significantly. The low-carbon variants are malleable and ductile, while high-carbon variants are hard and strong. The right grade of carbon steel can be selected based on the specific requirements of a construction project.

One of the defining characteristics of high-quality carbon steel pipes is their exceptional tensile strength. They can withstand high pressure and heavy loads, making them suitable for applications in energy, construction, and manufacturing. Additionally, carbon steel pipes exhibit good weldability and machinability, which simplifies the construction process and reduces labor costs.

Applications in Construction

In the construction sector, carbon steel pipes are utilized in various forms. They can be found as structural elements in buildings, used for pipelines that transport fluids and gases, and in the implementation of HVAC (heating, ventilation, and air conditioning) systems. Their application extends even further into fire protection systems, irrigation, and drainage systems, where strength and reliability are paramount.

high quality carbon steel pipe construction

For instance, in oil and gas operations, high-quality carbon steel pipes are essential for transporting crude oil, natural gas, and refined products. The high strength and resistance to environmental degradation make them ideal for this purpose. Similarly, in the water supply sector, these pipes are utilized to ensure the safe and efficient transport of potable water and wastewater.

Construction Considerations

When constructing with high-quality carbon steel pipes, certain factors must be taken into account. The selection of appropriate corrosion protection methods is crucial, as carbon steel is susceptible to rust and degradation over time when exposed to moisture and certain chemicals. Techniques such as galvanization, the application of protective coatings, or the use of corrosion inhibitors can significantly enhance the longevity of the pipes.

Proper installation techniques must also be employed. The pipes should be cut, welded, and joined in ways that preserve their structural integrity. Adequate support must be provided to prevent sagging or misalignment, particularly in longer spans. Regular inspections and maintenance are essential to detect any potential issues early, ensuring that the system functions optimally throughout its intended lifespan.

Conclusion

In conclusion, high-quality carbon steel pipes are a cornerstone of modern construction, providing strength, versatility, and reliability across various applications. From the transportation of critical resources to supporting structural frameworks, their significance cannot be understated. As industries continue to evolve and demand more efficient materials, the role of high-quality carbon steel pipes will remain integral to the advancement of construction practices, ensuring safety, durability, and environmental suitability in an ever-changing landscape. Selecting the appropriate pipe, applying effective protective measures, and adhering to best installation practices are vital for maximizing the benefits of this remarkable material.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024