Jul . 31, 2024 20:46 Back to list

Exploring the Production Process and Quality Standards of Carbon Steel ERW Pipe Manufacturers

ERW Pipe Carbon Steel Factories An Overview

Electric Resistance Welded (ERW) pipes have emerged as a cornerstone in various industries, including construction, oil and gas, and infrastructure development. The manufacturing of ERW pipes from carbon steel involves a sophisticated process that not only ensures high quality but also adheres to stringent industry standards. In this article, we explore the significance of ERW pipe carbon steel factories, their manufacturing processes, and the applications of their products.

The Manufacturing Process

The production of ERW pipes begins with the careful selection of high-quality carbon steel coils. These coils are unwound and passed through a series of rollers that shape the steel into a cylindrical form. The edges of the steel are then brought together, and the welding process commences. This is where the name Electric Resistance Welding comes from—by applying heat through electrical resistance and pressure, the edges of the steel are fused together, creating a strong bond.

Once the pipe is welded, it is subjected to various quality control measures. These may include non-destructive testing techniques such as ultrasonic testing and X-ray inspection to ensure that there are no structural defects. After passing these inspections, the pipes are then cut to the desired lengths, and additional treatments, such as galvanization or coating, may be applied to enhance their corrosion resistance and longevity.

Importance of Quality Control

Quality control is a critical aspect of any ERW pipe carbon steel factory. The integrity and performance of the pipes depend heavily on the manufacturing process and the materials used. Strict adherence to international standards, like ASTM and API, is essential to ensure that the products meet specific mechanical and physical properties. Factories invest heavily in modern equipment and skilled labor to uphold these standards, which ultimately leads to greater customer satisfaction and safety in applications.

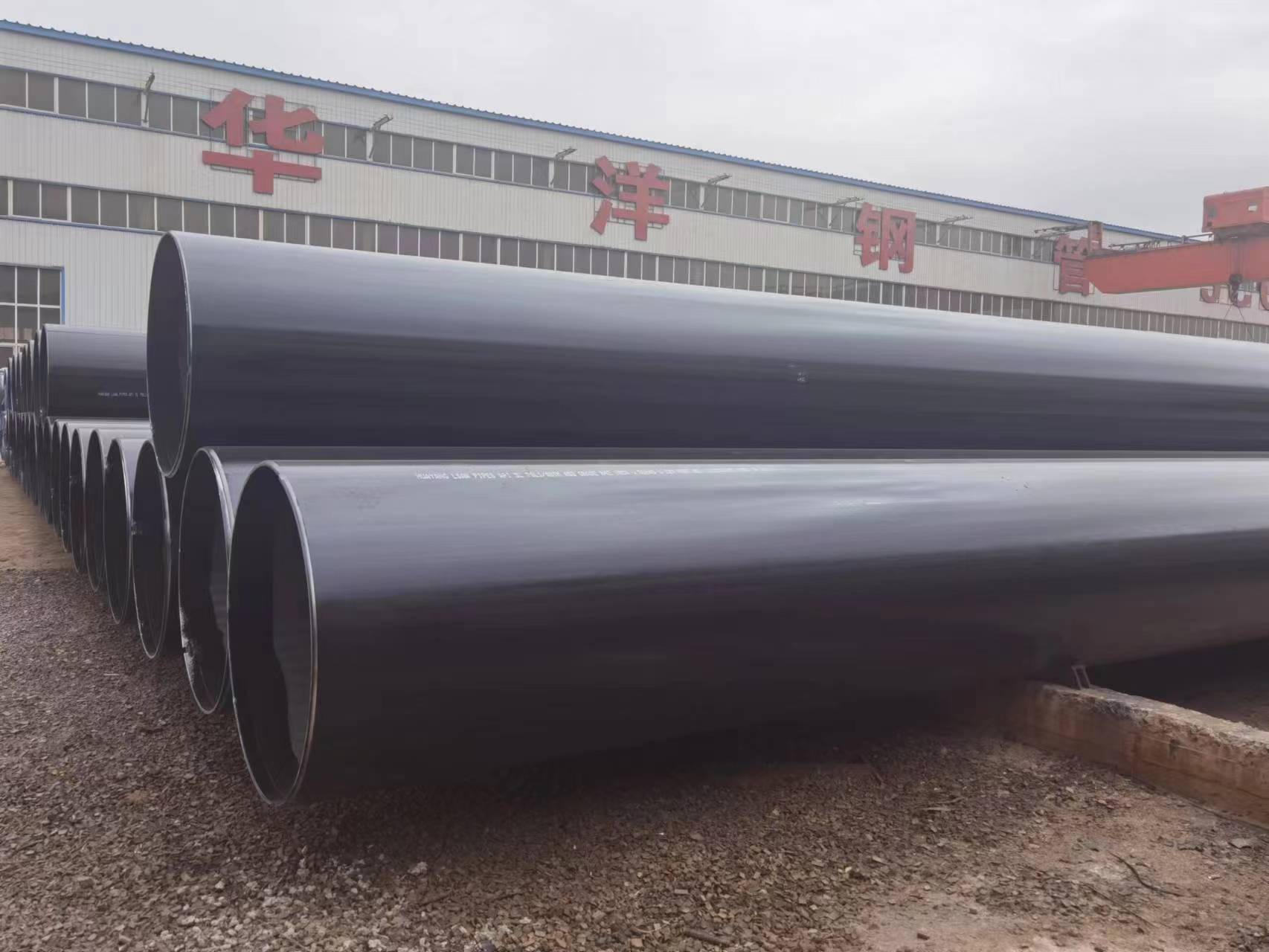

erw pipe carbon steel factories

Applications of ERW Pipes

ERW pipes made from carbon steel are widely used in various sectors. In the oil and gas industry, these pipes serve as vital components for transporting liquids and gases. Their high strength-to-weight ratio makes them ideal for both onshore and offshore applications. In the construction sector, ERW pipes are frequently used in structural applications, such as scaffolding and support beams, due to their robust nature.

Moreover, the water supply and sewage sectors also benefit from the use of ERW pipes. Their ability to withstand high pressures makes them suitable for transporting water in urban environments, while also being effective in managing waste materials. The versatility of ERW pipes has made them indispensable in many infrastructure projects around the globe.

Environmental Considerations

ERW pipe carbon steel factories are also adapting to the growing need for environmentally sustainable practices. Many factories are implementing recycling protocols and enhancing energy efficiency in their manufacturing processes. The use of high-quality carbon steel not only ensures durability but also reduces the overall carbon footprint of the products. Additionally, newer production methods aim to minimize waste and emissions, contributing to a more sustainable manufacturing landscape.

Conclusion

In summary, ERW pipe carbon steel factories play a crucial role in meeting the demands of various industries. With their advanced manufacturing processes, stringent quality control measures, and commitment to sustainability, these factories are at the forefront of providing high-quality products that meet the needs of modern infrastructure. As technology continues to evolve and industries seek more efficient and sustainable solutions, the importance of ERW pipes made from carbon steel will undoubtedly continue to grow.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024