Tag/hollow section

Produtct Title

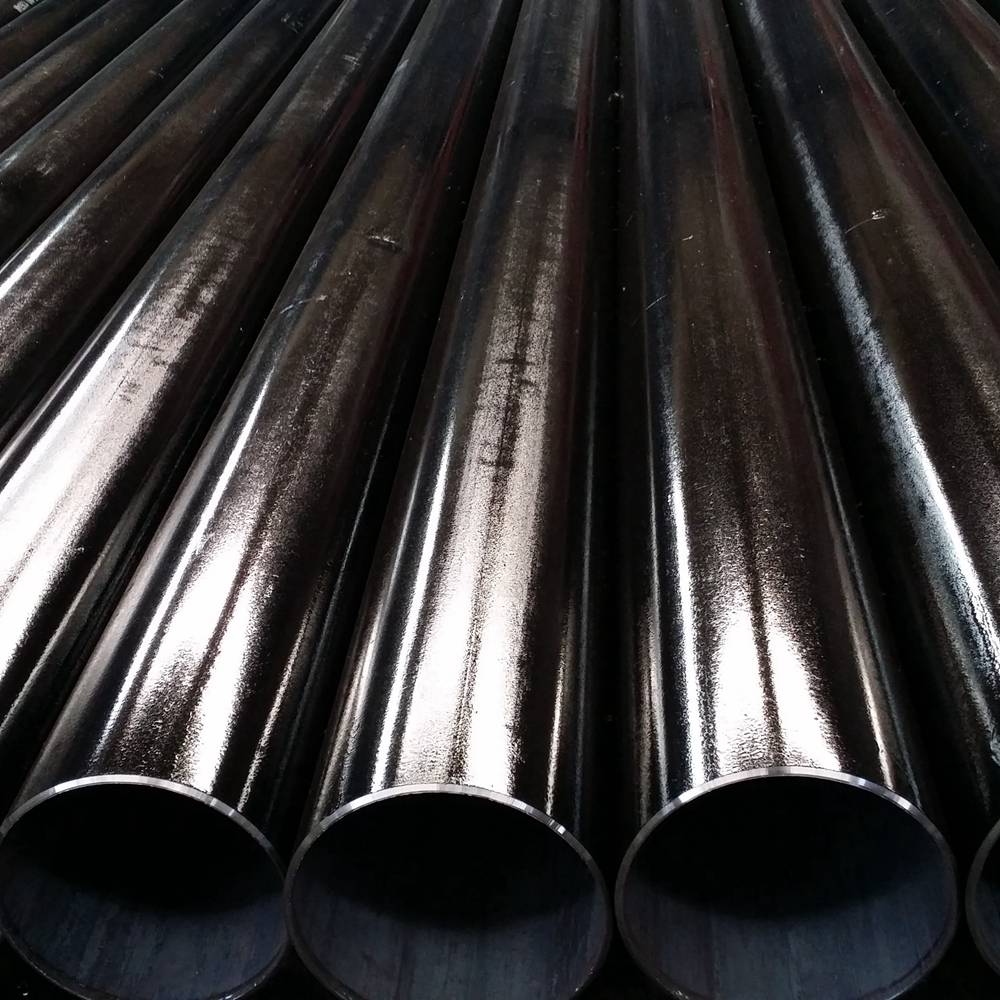

hollow section-

ASTM A252 Piling Pipe application in buildings and retaining walls

-

API 5L Black Oil / Gas Line Pipe

-

TUBE FOR PRESSURE PURPOSES

-

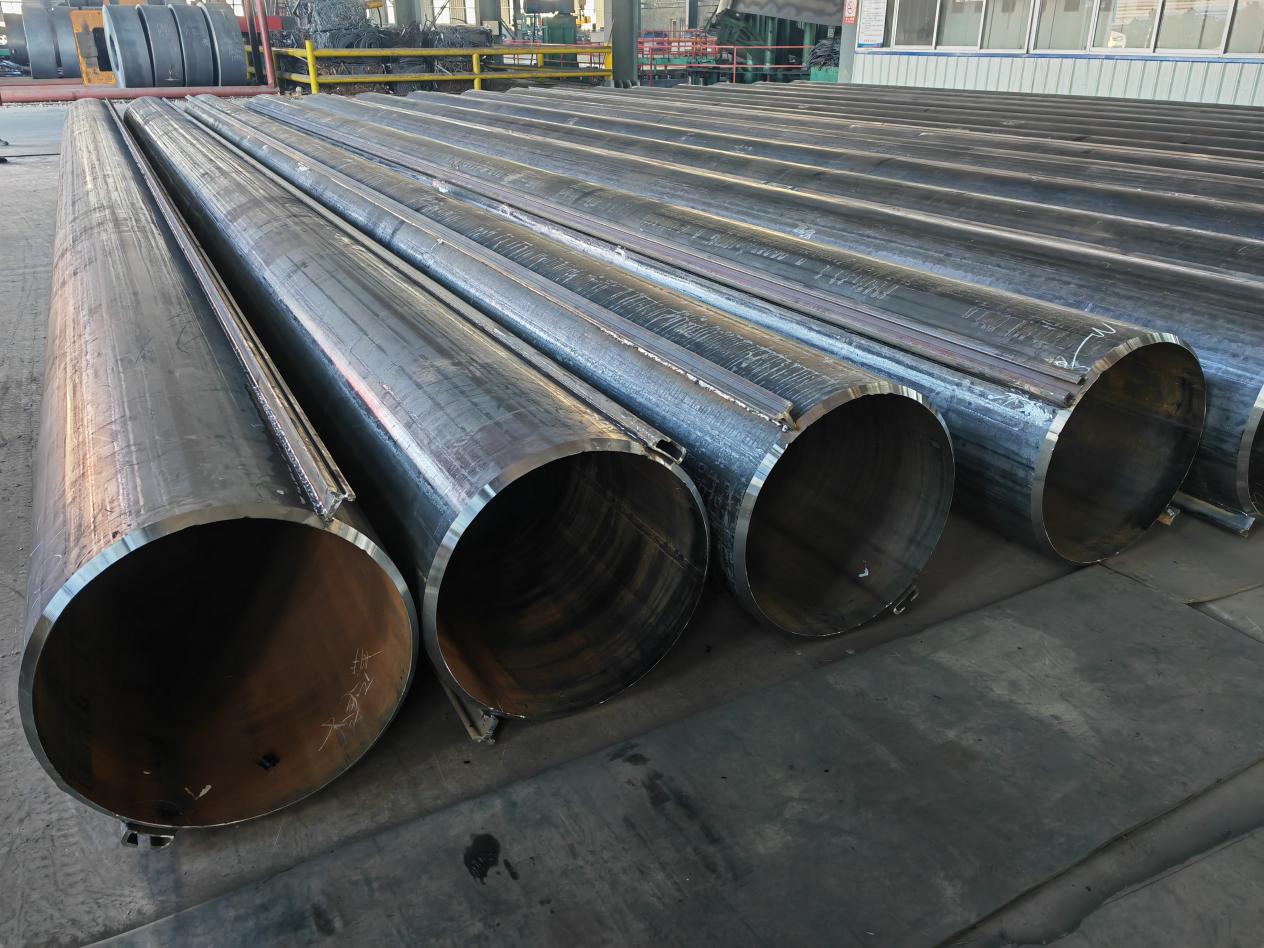

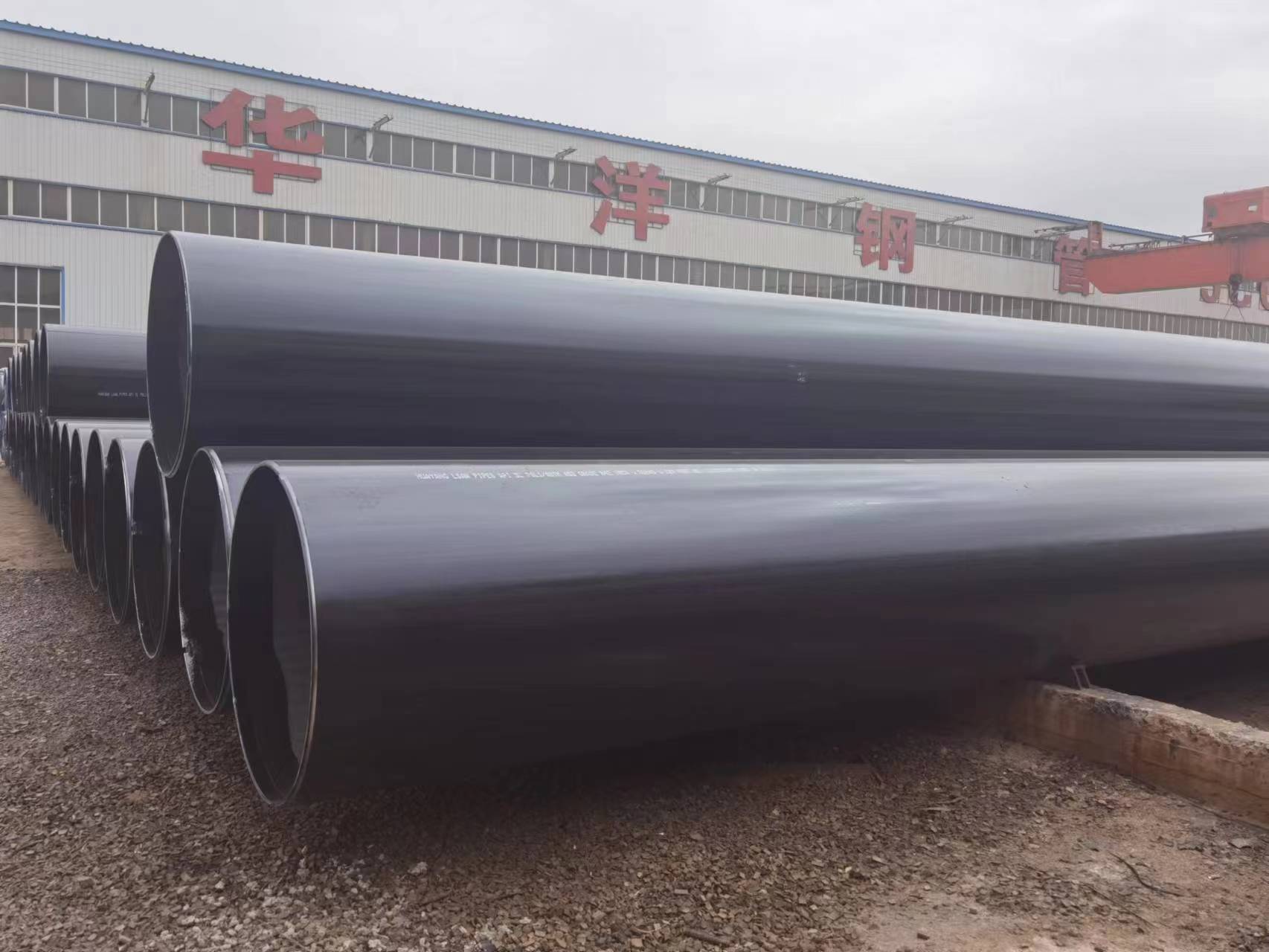

API 5L Pipe Line, Oil & Gas LinePipe, LSAW Steel Pipe

-

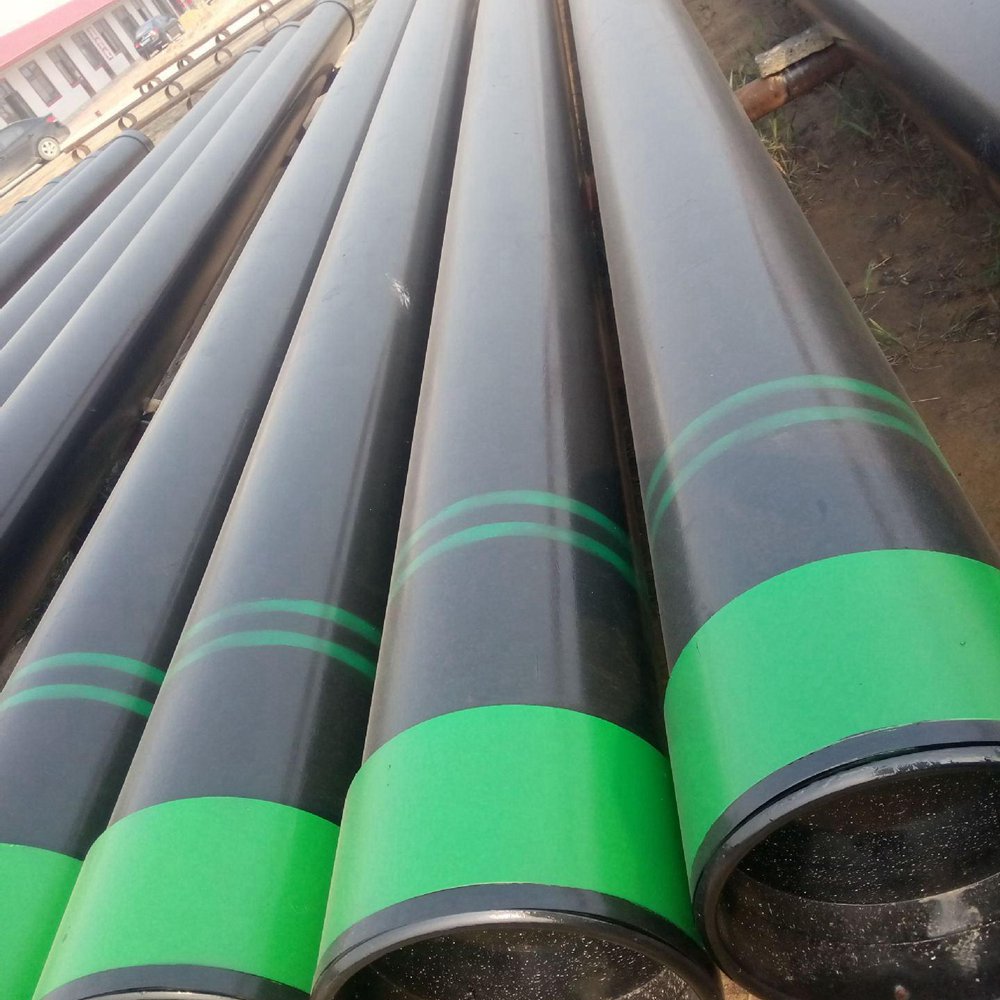

API 5CT TUBING CASING PIPE, OCTGOIL COUNTRY TUBULAR GOODS

-

Boiler Steel Pipe

-

High pressure and temperature Alloy Seamless Steel Pipe

-

EFW Steel Pipe

-

Metal welding services

Related News

-

2024-06-20Chinese manufacturers specialize in hollow section production.China's Leading Manufacturers of Hollow Section Steel ProductsChina, known for its robust manufact

-

2024-07-27Exploring the Benefits and Applications of High-Quality Hollow Steel Structures in Modern EngineeringHigh-Quality Hollow Sections An OverviewIn the realm of construction and manufacturi

-

2024-07-27Innovative Solutions from Leading Hollow Section Manufacturers for Structural and Engineering ApplicationsHollow Section Manufacturers A Key Player in Modern ConstructionIn the world of con

-

2024-01-25Stainless Steel: How it is MadeToday we are taking a deep dive into stainless steel and how it is made. This type of steel is widely used. Chances are you own at least a few appliances that are made of stainless. I know my refrigerator is.

-

2024-11-22lsaw steel pipe-Brief Description and Comparisons of LSAW, SSAW, and ERW Pipes-lsaw steel pipeHigh quality steel pipes are produced from three (3) manufacturing processes: Seamless, LSAW (longitudinal-seam submerged arc welding), and ERW (electric resistance welding). LSAW and ERW pipes are highly regarded for their numerous fields of application. They are tremendously used in foundation solutions and systems, marine construction, structural construction, and diverse applications in water projects, petrochemical, chemical, and power industry, agricultural irrigation, urban construction, and more.

-

2024-11-22Stainless steel-How To Clean Stainless Steel Appliances with Vinegar and OilStainless steel appliances look great in the kitchen, but they’re prone to showing hard water marks and fingerprints. You frequently see this on the dishwasher (so many water stains!) and the handles of the refrigerator (hello, overuse).So, to restore my flat and dirty appliances back to their happy, shiny, robot-looking selves, I decided to make my trusty stainless steel toaster my test subject. What would I need to get it looking like new again?

-

2024-11-22ERW Pipe-stainless steel Different kinds of corrosion on stainless steelStainless steel is the most durable of metals. Its mechanical properties enable its structures to remain extremely resistant to rust. Nevertheless, corrosion can’t be precluded. But there are ways to mninimize the risk of corrosion.

-

2024-08-01Leading Manufacturers of Welded LSAW Steel Pipes for Various Industrial Applications and SolutionsUnderstanding Welded LSAW Steel Pipe ManufacturersWelded Large-Diameter Submerged A

-

2024-11-22WHAT'S THE DIFFERENCE BETWEEN STEEL PIPES AND STEEL TUBES?-ERW Steel PipeSteel pipe has been produced in the US since the early 1800s. Pipe is a hollow section with a round cross-section, primarily made for the transportation of products including fluids, gas, pellets, powders, and more. But steel pipes are used in a variety of ways. They are used underground for transporting water and gas throughout cities and towns. They are also specified in construction to protect electrical wires. Steel pipes can be strong, but lightweight. This makes them great for bicycle frames. They are also used in the making of parts for automobiles, refrigeration units, heating and plumbing systems, flagpoles and street lamps, just to name a few.

-

2024-03-14Benefits of pipe pilingSteel pipe piles are products made of steel pipes, tongues and grooves, and tenon pins. Pipe piling overlap each other to form an arc or circle. They can be used to contain water, sand, etc., and are intended to be used in offshore docks. Steel pipe pile is a kind of steel pile material. Typically refers to seamless or welded (SSAW or LSAW) manufactured carbon steel pipes used to support and stabilize a building's foundation.

-

2024-11-22Welded Steel Pipe-7 Cleaning Methods To Clean Stainless SteelWhile the distinct look of stainless steel appliances has only added to their popularity over the years, knowing how to clean them properly is key to maintaining that brilliant, just-like-new shine for years to come. To achieve this, it’s best to skip harsh, store-bought chemicals and opt for a homemade, natural stainless steel cleaner instead. Here, we break down how to clean your stainless steel appliances step by step and offer seven different methods to keep appliances like pots, pans, tumblers, and other stainless steel objects looking shiny and new.

-

2024-01-31ERW Steel Pipe-CLEANING STAINLESS STEEL: HERE’S HOW TO LOOK AFTER YOUR SINKIt’s here at last: your new stainless steel sink! The shine of a newly installed sink will attract plenty of admiring glances. If you want to keep it that way, you need to know how to clean and maintain stainless steel properly. This includes daily cleaning, removing limescale and monthly deep-cleaning.

-

2024-07-26Top Wholesale Suppliers for Blocked Water Pipe Solutions and Quality Plumbing ProductsWholesale Blocked Water Pipe Suppliers An Essential Resource for Consumers and Businesses

-

2024-07-28Top Quality OEM LSAW Welded Steel Pipe Manufacturers for Your Industrial Needs and SolutionsThe Importance of High-Quality OEM LSAW Welded Steel Pipe SuppliersIn the modern in

-

2024-07-26Top Seamless Steel Pipe Manufacturers in China for Quality and EfficiencySeamless Steel Pipe Manufacturers in China An OverviewChina has emerged as a global

-

2024-07-25Top Supplier of High Quality ERW Welded Steel Pipes for Various Industrial ApplicationsHigh-Quality ERW Welded Steel Pipe Supplier Ensuring Strength and DurabilityIn the r

-

2024-07-26Leading Supplier of High-Quality ERW Galvanized Steel Pipes for Wholesale Distribution and Manufacturing NeedsThe Rise of Wholesale ERW Galvanized Steel Pipe ManufacturersIn the landscape of mo

-

2024-06-13ERW steel pipes from leading factoriesUnderstanding the World of ERW 20 Steel Pipe Prices and Manufacturing FactoriesERW (Electric Resis

-

2024-06-15Provider of pipeline systemsThe Pivotal Role of Pipeline Suppliers in the Global Infrastructure SectorIn the complex tapestry

-

2024-07-23Top Wholesale Suppliers for Construction Pipes and Materials in the Industry TodayThe Rise of Wholesale Construction Pipe Suppliers A Critical Component in Modern Infrastructure

Related Search

- hollow section

- high quality hollow section

- china hollow section

- wholesale hollow section

- hollow section exporter

- hollow section factory

- hollow section factories

- hollow section manufacturers

- hollow section supplier

- hollow section manufacturer

- hollow section exporters

- hollow section suppliers

- wholesale hollow section factory

- wholesale hollow section manufacturer

- wholesale hollow section factories

- wholesale hollow section exporters

- wholesale hollow section supplier

- wholesale hollow section manufacturers

- wholesale hollow section suppliers

- wholesale hollow section exporter

- china hollow section factory

- china hollow section manufacturer

- china hollow section factories

- china hollow section exporters

- china hollow section supplier

- china hollow section manufacturers

- china hollow section suppliers

- china hollow section exporter

- high quality hollow section factory

- high quality hollow section manufacturer