Блог

-

Brief description and comparison of LSAW, SSAW and ERW pipes-lsaw steel pipe-ERW Steel Pipe

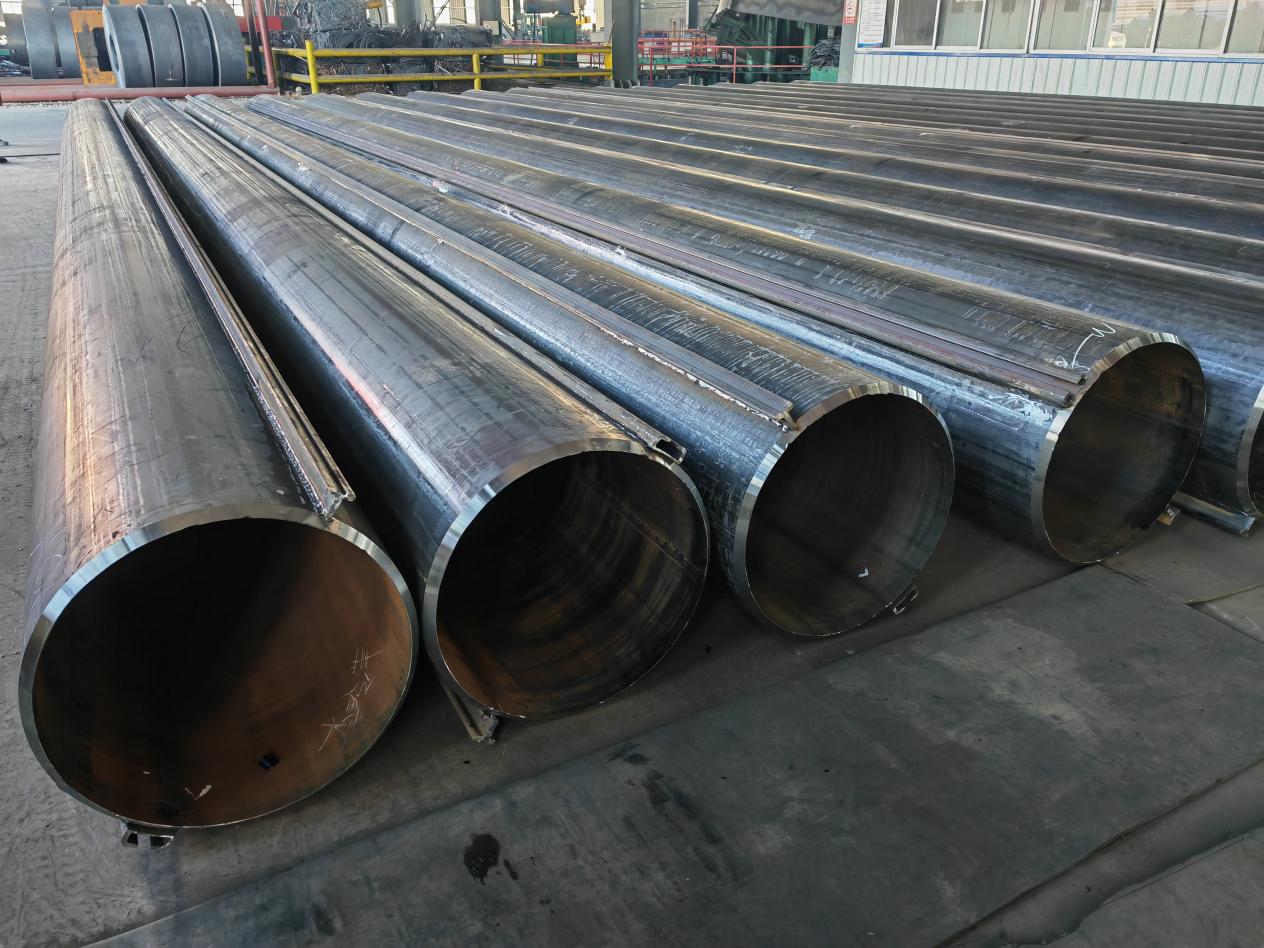

Brief description and comparison of LSAW, SSAW and ERW pipes-lsaw steel pipe SSAW pipes have greater residual stresses than LSAW pipes. The straight seam submerged arc welded pipe undergoes a uniform expansion process. The stress concentration phenomenon of SSAW pipe welds belongs to the severe category. SSAW pipes have a larger heat affected zone than LSAW pipes. The heat-affected zone is considered a weak point where failure may begin. The geometric accuracy of LSAW pipe is better than that of SSAW pipe, which is the key to ease of installation. LSAW pipe has approximately 60% fewer welds than SSAW pipe. ASTM A252 Piling Pipe application in buildings and retaining walls Brief description and comparison of LSAW, SSAW and ERW pipes Quality steel pipe is produced by three (3) manufacturing processes: Seamless, LSAW (Longitudinal Submerged Arc Welding) and ERW (Electric Resistance Welding). LSAW and ERW tubes are highly regarded for their wide range of applications. They are widely used in basic solutions and systems, marine construction, structural construction, and various applications in the fields of hydraulic engineering, petrochemical, chemical and power industries, agricultural irrigation, and urban construction. LSAW pipe comes in two types: longitudinal (single or double straight seam weld, DSAW) and helical (also known as SSAW, HSAW or SAWL). LSAW pipe differs from other LSAW pipes in that LSAW pipe has a seam weld on the inside and outside of the pipe, while the latter has only one seam weld on the outer surface, longitudinal or cross-section. SSAW and LSAW pipes are manufactured using a common manufacturing process known as the "JCOE and UOE Forming Process". The difference is that SSAW pipes are welded in a helical or helical position while LSAW pipes are welded longitudinally. The SSAW pipe is wound and welded by steel strip, its rotation direction is inclined to the axis or the center of the pipe, and the weld seam is helical. LSAW pipe is made by forming a steel plate into a cylinder and joining the ends together by straight-line welding. LSAW pipe diameters typically range from 16" to 60" (406mm to 1500mm). They have good high pressure and low temperature corrosion resistance. However, CSC Steel can supply pipe with diameters between 1 inch and 167 inches (21 mm and 4267 mm) and thicknesses between 3/32 inch and 4 inches (2.1 mm and 100 mm). ESC steel pipe is manufactured using LSAW in maximum diameter and thickness and is highly recommended for load bearing piles, composite wall piles and other applications. In the oil and gas industry, large diameter API 5L LSAW pipe is used to efficiently transport hydrocarbons over long distances. HSAW (Spiral Submerged Arc Welding) or SSAW pipe diameters typically range from 20" to 100" (406 mm to 2540 mm). One of the advantages of SSAW is the possibility of obtaining different diameters ERW pipe ERW Tube Forming SSAW pipe is made from standard size steel strip without cutting. On the other hand, the length of the spiral weld is much longer than the length of the pipe, the cost is higher, and it is prone to cracks, pores, slag inclusions, partial welding, etc. HSAW or spiral welded pipe is used in non-critical applications such as water distribution and not for oil and gas. CSC recommends SSAW pipes as main piles and dredging pipes for our composite walls.Ары қарай оқу -

Seamless Pipe-Welded Steel Pipe

Steel pipes come in many forms and sizes. Seamless pipes are a non-welded option produced from hollowed-out steel billets. When it comes to welded steel pipes, there are three options: ERW, LSAW and SSAW.ERW pipes are made from electric resistance welded steel plates. LSAW pipes are made from longitudinally submerged arc welded steel plates. SSAW pipes are made from spiral submerged arc welded steel plates.Steel pipes are typically used in the oil and gas industry for exploration and extraction (upstream), the transmission of fluids like oil, gas and slurries (midstream) and oil refinement into derivative products (downstream). They are also used for agricultural irrigation, urban construction and more.Let’s take a closer look at each type of pipe, comparing their differences and how to make an order with the right description.Ары қарай оқу -

What is the difference between SSAW and LSAW pipes?-lsaw steel pipe-ERW Steel Pipe

SSAW (Spiral Submerged Arc Welding) and LSAW (Longitudinal Submerged Arc Welding) are two different methods used for manufacturing welded steel pipes. Here's a comparison of the main differences between SSAW and LSAW pipes:Formation process:SSAW Pipe: The spiral welding process involves forming the steel strip into a spiral shape and then welding the edges using the submerged arc welding method.LSAW Pipe: The longitudinal welding process involves forming a straight, cylindrical pipe from a single steel plate or coil and then welding along the length of the pipe using the submerged arc welding technique.Ары қарай оқу -

LSAW large-diameter pipe plants-lsaw steel pipe

In LSAW pipe mills, processing is done by cold forming of heavy carbon steel plates. Among the available forming processes, SMS group focuses on the JCO technology. We supply the equipment for all important process steps from plate preparation to forming, welding, testing, and finishing. Including not only the core machines, but also all the upstream and downstream process steps required for the production of large-diameter pipes.Our plants stand for high product quality at medium to high output, flexible and cost-effective processes, precise dimensions, and close pipe tolerances.Ары қарай оқу -

China Steel Pipe-Diameter expansion of LSAW steel pipe-lsaw steel pipe

LSAW steel pipe is a welded pipe produced by pressing (rolling) the steel plate into a tube blank in a mold or a forming machine, and using a double-sided submerged arc welding method and expanding the diameter. The finished product has a wide range of specifications, good toughness, plasticity, uniformity and compactness of the weld, and has the advantages of large pipe diameter, pipe wall thickness, high pressure resistance, low temperature resistance and strong corrosion resistance.LSAW steel pipe expansion is a pressure processing process that uses hydraulic or mechanical means to apply force from the inner wall of the steel pipe to expand the steel pipe radially outward. The mechanical method is simpler and more efficient than the hydraulic method, and the steel pipe machining is more accurate under the condition of high precision.The expansion process of LSAW steel pipe is divided into mechanical expansion and hydraulic expansion.Ары қарай оқу -

China Steel Pipe-Differences Between ERW and LSAW Steel Pipe-lsaw steel pipe

Straight seam welded steel pipes are divided into high frequency resistance welding and submerged arc welding according to the welding process. Straight seam submerged arc welding is referred to as LSAW, and longitudinal high frequency resistance welding is referred to as ERW.Compared with submerged arc welding, high frequency electric resistance welded steel pipes (ERW steel pipes) do not add any welding materials during the welding process in the ERW process, and the weld formation does not undergo a thermal melting state, but the weld metal undergoes a recrystallization process. Therefore, the formed weld seam is completely consistent with the chemical composition of the base metal. After the steel pipe is welded, it is annealed to produce the cold working internal stress and welding internal stress. Therefore, the comprehensive mechanical properties of the ERW steel pipe are better.Ары қарай оқу -

LSAW Pipes and Their Applications-lsaw steel pipe-Welded Steel Pipe

Бойлық су астындағы дәнекерленген (LSAW) құбырларды өндіру процесі әртүрлі өнеркәсіптік қолданбалар үшін берік және сенімді болат құбырларды шығаруға арналған күрделі және дәл процедура. Процесс әдетте болат орамды ағытудан басталады, содан кейін ол тегістеледі және қажетті өлшемге дейін кесіледі. Содан кейін дайындалған болат жолақ иілу операцияларының сериясы арқылы цилиндрлік пішінге келтіріледі. Кейіннен бойлық дәнекерлеу доғалық дәнекерлеу әдісімен жүзеге асырылады. Бұл болат пластинаның шеттерін үздіксіз электр доғасымен балқыту арқылы құбырдың ұзындығы бойынша жоғары сапалы дәнекерлеу тігісін жасауды қамтиды, ал түйіршікті ағын дәнекерлеу аймағын қорғайды, таза және тиімді дәнекерлеуді қамтамасыз етеді. UOE жағдайында. (Uing және Oing) LSAW құбырлары, бастапқы дәнекерлеуден кейін құбыр қажетті өлшемдер мен механикалық қасиеттерге қол жеткізу үшін Uing, Oing және кеңейту процестерінен өтеді. Сол сияқты, JCOE (J-ing, C-ing, O-ing және E-ing) LSAW құбырлары бірнеше қадамдарды қамтиды, соның ішінде бастапқы пішінді қалыптастыру үшін J-ing және C-ing, одан әрі пішіндеу үшін O-ing және Соңғы кеңейтуге арналған электронды. Бұл процестер LSAW құбырларының жалпы беріктігі мен тұтастығына ықпал етіп, олардың қатаң сапа стандарттарына сәйкес келуін қамтамасыз етеді. Өндіріс процесінің соңғы қадамдары әртүрлі өнеркәсіптік орталарда құбырлардың өнімділігі мен ұзақ қызмет ету мерзіміне кепілдік беру үшін тексеруді, сынауды және жабуды қамтиды.Ары қарай оқу