Tag/as 1163 c350

-

API 5L Line Pipe Seamless Steel Pipe

-

Metal welding services

Metal welding services -

API 5L Black Oil / Gas Line Pipe

API 5L Black Oil / Gas Line Pipe -

TUBE FOR PRESSURE PURPOSES

TUBE FOR PRESSURE PURPOSES -

Structural Steel Pipe

Structural Steel Pipe -

TUBE FOR CONVEYANCE OF FLUID

-

Boiler Steel Pipe

Boiler Steel Pipe -

ASTM A252 Piling Pipe application in buildings and retaining walls

ASTM A252 Piling Pipe application in buildings and retaining walls -

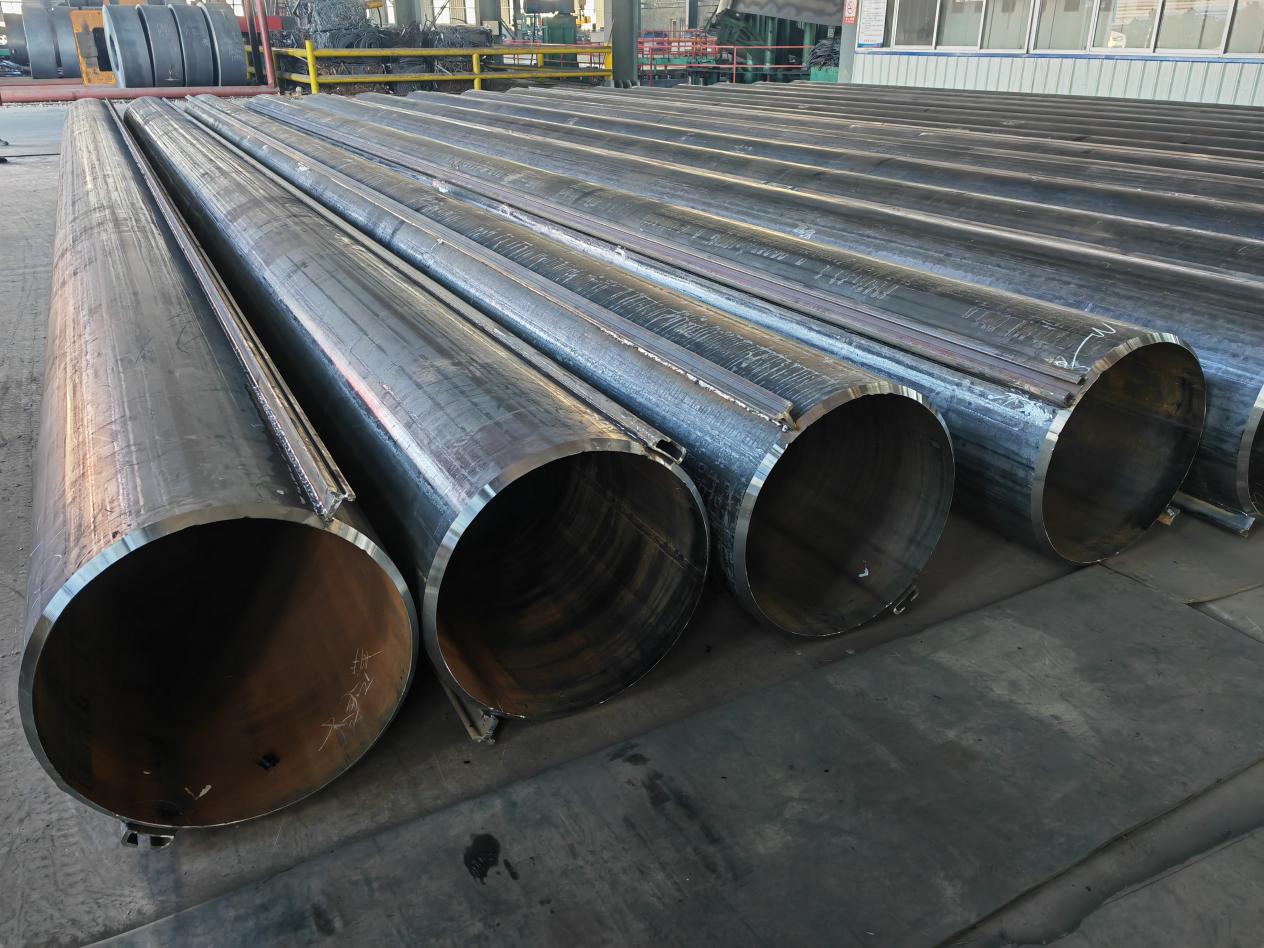

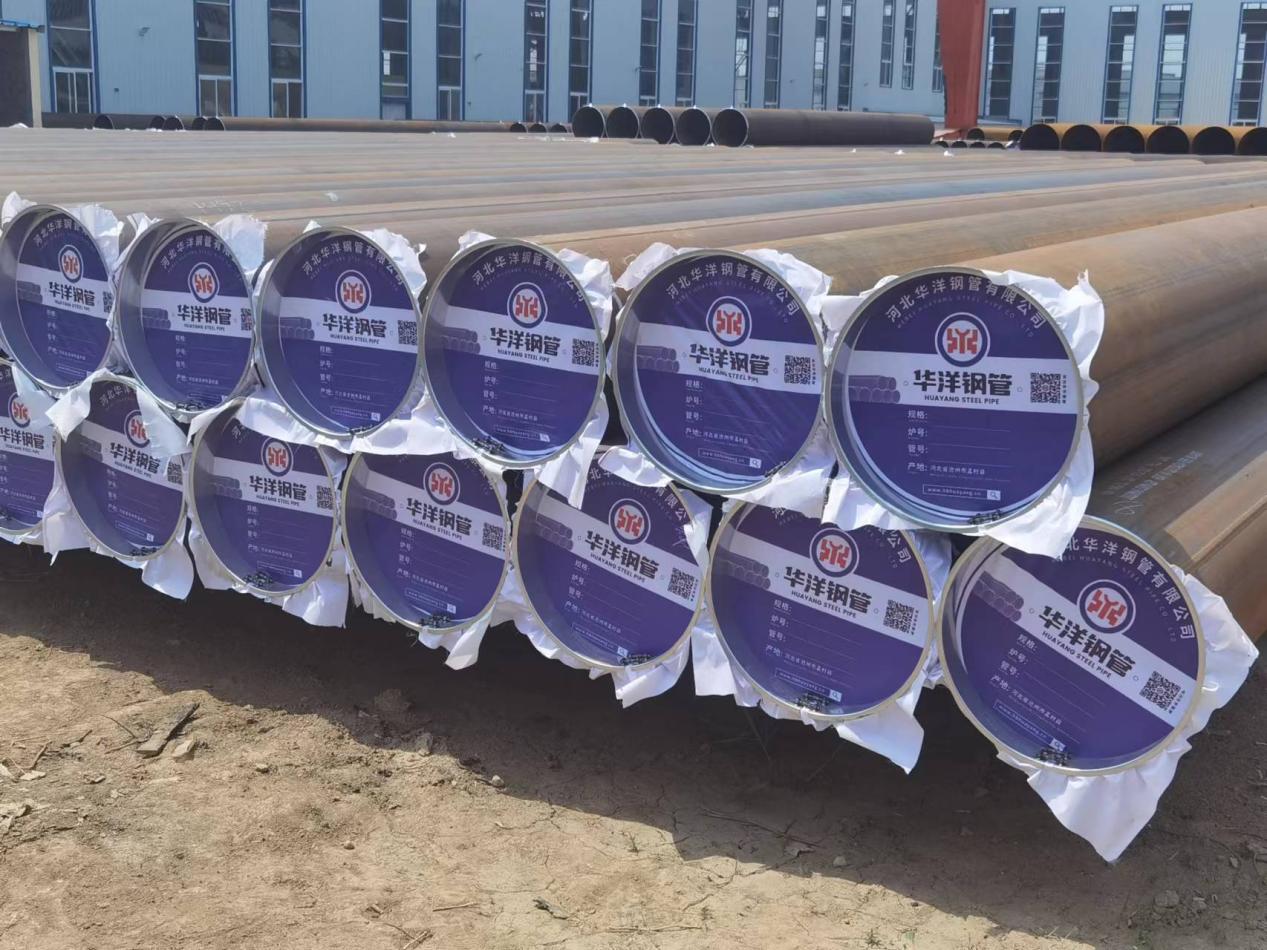

Submerged arc welded steel pipe

Submerged arc welded steel pipe -

Mechanical Tube

Mechanical Tube

Produtct Title

as 1163 c350-

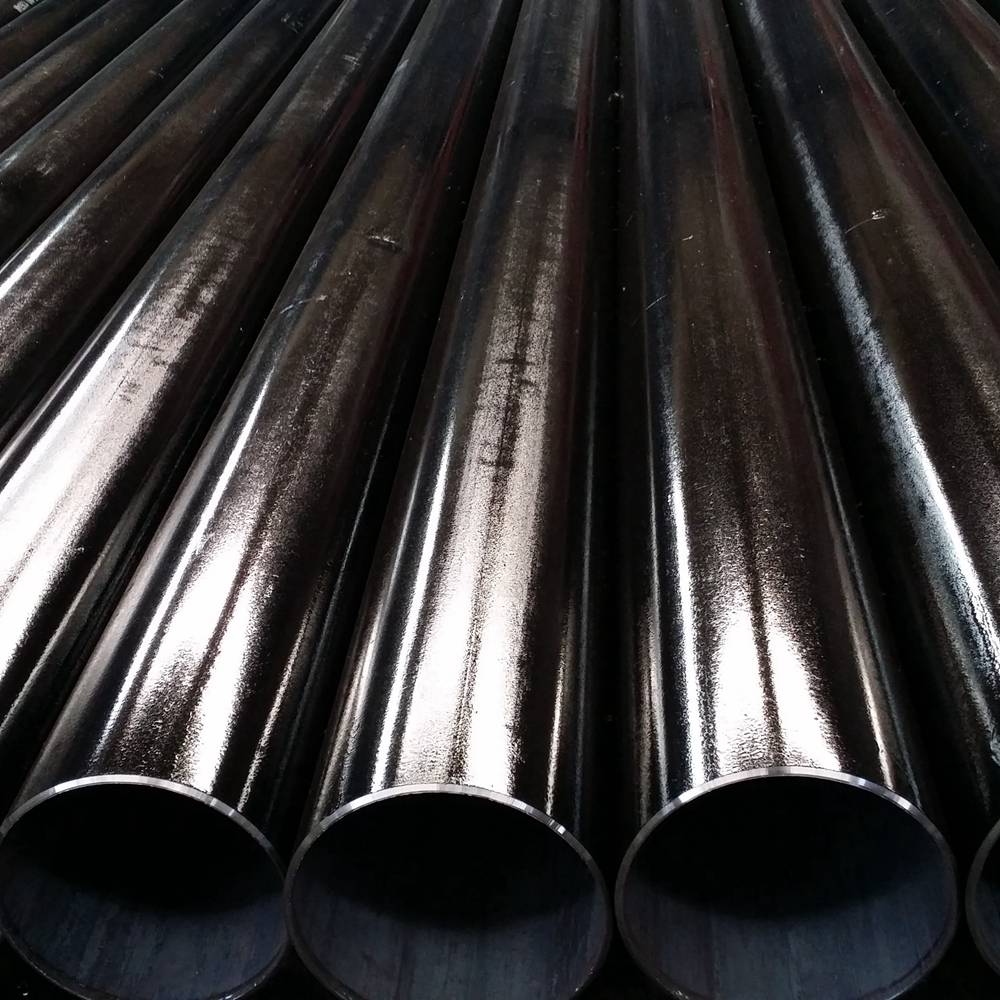

A53 ERW STEEL PIPE

-

EFW Steel Pipe

-

HFW steel pipe

-

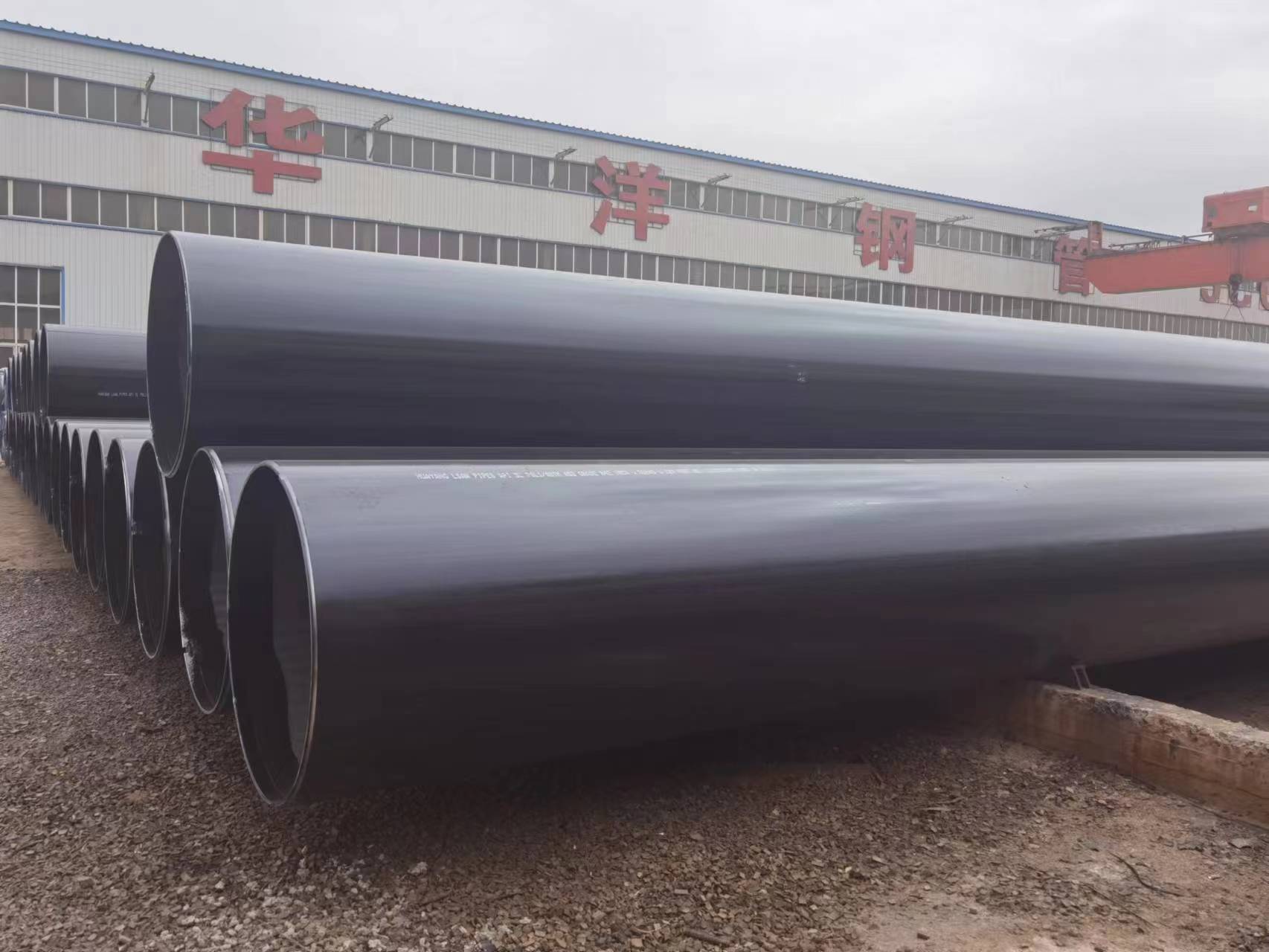

3LPE Coated Steel Pipe used in pipeline transportation

-

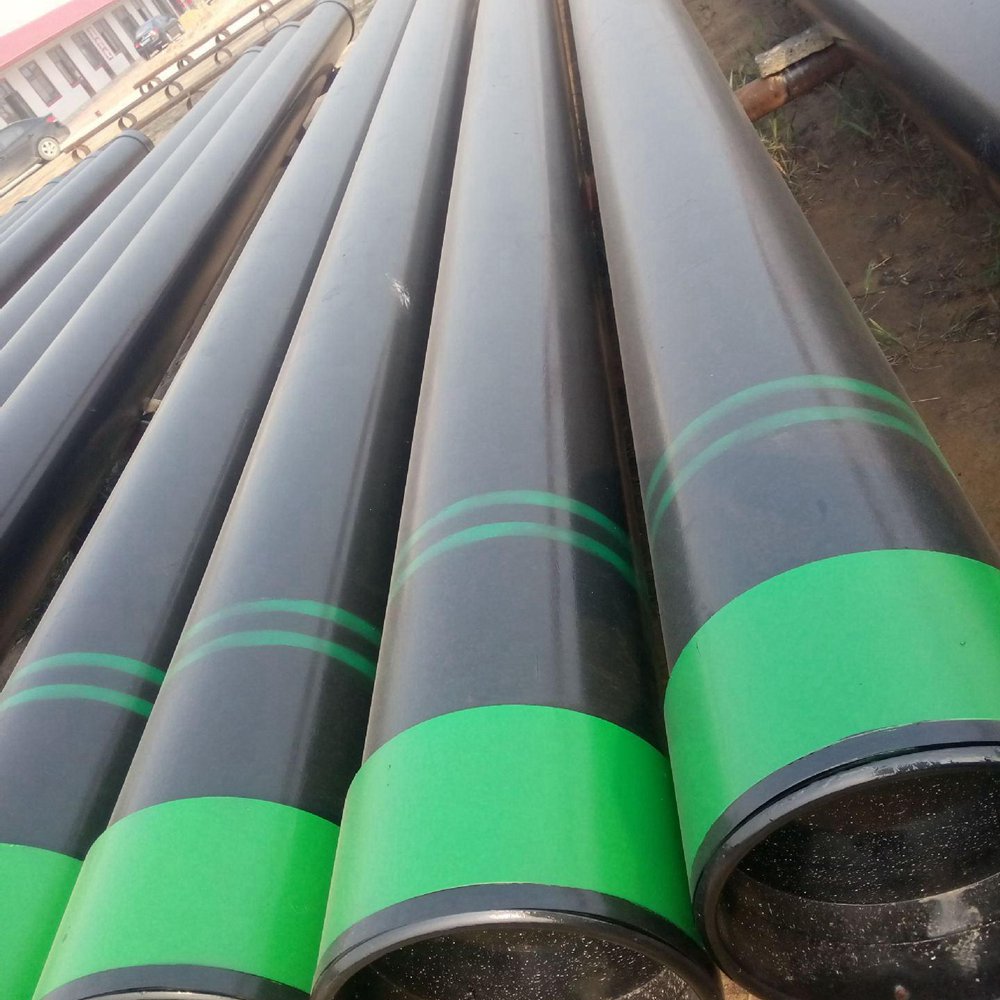

API 5CT TUBING CASING PIPE, OCTGOIL COUNTRY TUBULAR GOODS

-

API 5L Pipe Line, Oil & Gas LinePipe, LSAW Steel Pipe

-

Carbon Steel Pipes

-

High pressure and temperature Alloy Seamless Steel Pipe

-

Welded Steel Pipe

Related News

-

2024-06-12Suppliers of top-grade 1163 C350, ensuring premium quality.High-Quality 1163 C350 The Benchmark for Suppliers In the realm of industrial materials and compon

-

2024-06-27Wholesale Dealers of 1163 C350 Models for Global Export MarketsThe Dynamic World of Wholesale Exporters A Dive into the Business of Wholesale as 1163 C350 Exporter

-

2024-07-28Top Manufacturers Offering High-Quality 1163 C350 Solutions for Various Industrial ApplicationsHigh Quality Manufacturing Insights from 1163 C350 ManufacturersIn today's competiti

-

2024-06-27Wholesale ASTM A672 Steel Plates Find a Reliable Supplier for Your Project NeedsEnsuring Quality and Compliance with Wholesale ASTM A672 SuppliersIn the world of wholesale metal

-

2024-06-12Premier provider of top-grade steel tubular productsHigh-Quality Steel Tubular Suppliers The Backbone of Robust Infrastructure In the realm of constru

-

2024-06-23Pipe Construction ProductsPipeline Construction Products A Crucial Aspect of Infrastructure DevelopmentPipeline construction

-

2024-07-28Top Manufacturer of Premium A500 ERW Steel Pipes and Tubes for Various ApplicationsHigh-Quality A500 ERW Steel Pipe Tubes Manufacturer A Comprehensive OverviewIn the

-

2024-07-30Manufacturer of electric resistance welded pipes in China, supplying high-quality products worldwide.China is a leading producer of electric resistance welded (ERW) pipes, which are widely used in vari

-

2024-07-31Leading Manufacturer of Premium Quality Piping Solutions for Diverse Industrial Applications and NeedsHigh Quality Pipeline Manufacturer Ensuring Excellence in InfrastructureIn today's r

-

2024-06-15API-certified manufacturer of cement-coated steel pipesAPI Certified Cement Lined Steel Pipe Manufacturers Pioneers in Robust Pipeline SolutionsIn the wo

-

2024-11-22Stainless steel-HOW TO CLEAN STAINLESS STEELStainless steel was originally developed for cutlery. Its resistance to corrosion and oxidation earned it the name “stainless” — although it’s not actually steel. (Stainless steel contains at least 10.5 percent chromium and other elements like nickel, titanium and copper.)This material is now commonly used for countertops and appliances like refrigerators, microwaves and dishwashers. The finish looks sleek and modern while being strong and durable. Stainless steel is also popular because it’s typically easy to clean and maintain.Keep reading for tips on how to clean, maintain and protect your stainless steel appliances and surfaces and keep them looking shiny and new.

-

2024-07-12Wholesale factories specializing in underwater pipe construction production and distributionWholesale Underwater Pipe Construction FactoriesUnderwater pipe construction is a vital aspect of

-

2024-07-11Get wholesale LSAW pipes for New Zealand with great deals and discounts.Wholesale LSAW Pipe to New ZealandWhen it comes to sourcing high-quality LSAW (Longitudinal Submer

-

2024-07-26Reliable Exporter of High-Quality ERW Steel Pipes for Global Markets and IndustriesThe Emergence of Tube ERW Steel Pipe Exporters in Global MarketsIn recent years, th

-

2024-11-22ERW Pipe-How to Clean Stainless Steel AppliancesDid you ever get your haircut, and you loved it when the stylist was finished... but then the next time you showered and tried to do your hair, it just didn't look the same? That kind of phenomenon occurs in many parts of life, including with stainless steel appliances. You remember how great your stove looked in the showroom at the store? Or how shiny the fridge was in the photos? And now look; fingerprints, stains, drips, streaks... is it hopeless? No! There are lots of great ways to clean stainless steel appliances, and many of them are quite inexpensive!

-

2024-01-26Stainless steel-The Ultimate Guide to Cleaning and Maintaining Your Stainless Steel AppliancesStainless steel appliances are an investment, and maintaining their shine and luster is essential for their longevity. Here’s how to clean stainless steel appliances:Step 1: Dust off the surface of the appliance with a soft cloth or microfiber towel to remove any loose dirt or debris.Step 2: Mix a cleaning solution of warm water and a mild detergent or dish soap.Step 3: Dip a soft cloth or sponge into the cleaning solution and wipe the surface of the appliance in the direction of the grain.Step 4: Rinse the cloth or sponge thoroughly and wipe the surface again to remove any residue.Step 5: Dry the appliance with a clean, dry microfiber towel to prevent water spots and streaks.

-

2024-07-27Wholesale Suppliers of 5L-B Carbon Steel Pipes for Industrial Applications and Construction NeedsThe Importance of Wholesale API 5L-B Carbon Steel Pipe FactoriesIn the modern const

-

2024-11-22Carbon Steel Pipe-stainless steel Does Stainless Steel Rust?Stainless steel is naturally corrosion-resistant, but it is not immune to rust. While it is less prone to rusting than conventional steels, exposure to damaging chemicals, saline, grease, moisture, or heat for extended periods of time can cause corrosion. The likelihood of corrosion depends on the chromium content of the stainless steel, with higher chromium content reducing the risk of rust formation.

-

2024-11-22stainless steel I have rusted stainless steel, I thought stainless steel couldn't rust?Yes! Stainless steel can rust. If you are experiencing rust on your 'stainless' steel, you are not alone as we often have customers call us looking for help with that very same issue; rust on their stainless steel.

-

2024-11-22SAW vs ERW and EFW Welded Steel Pipe-HOW TO REMOVE BROWN STAINS FROM STAINLESS STEEL SINK?Appliances in bathrooms, kitchens and other home areas are made of stainless steel, the most significant and influential steel. The popularity of stainless steel is due to its stunning appearance, gloss, and sparkle. Stainless steel sink can still get stains even if it is more stain-resistant than other steel forms. Never use harsh chemicals to remove these stains since they can harm or tarnish stainless steel. Instead, use reasonable cleaning solutions for removing brown stains from the stainless sink, which are listed below:

Related Search

- as 1163 c350

- high quality as 1163 c350

- china as 1163 c350

- wholesale as 1163 c350

- as 1163 c350 exporter

- as 1163 c350 factory

- as 1163 c350 factories

- as 1163 c350 manufacturers

- as 1163 c350 supplier

- as 1163 c350 manufacturer

- as 1163 c350 exporters

- as 1163 c350 suppliers

- wholesale as 1163 c350 factory

- wholesale as 1163 c350 manufacturer

- wholesale as 1163 c350 factories

- wholesale as 1163 c350 exporters

- wholesale as 1163 c350 supplier

- wholesale as 1163 c350 manufacturers

- wholesale as 1163 c350 suppliers

- wholesale as 1163 c350 exporter

- china as 1163 c350 factory

- china as 1163 c350 manufacturer

- china as 1163 c350 factories

- china as 1163 c350 exporters

- china as 1163 c350 supplier

- china as 1163 c350 manufacturers

- china as 1163 c350 suppliers

- china as 1163 c350 exporter

- high quality as 1163 c350 factory

- high quality as 1163 c350 manufacturer