1月 . 25, 2024 15:47 Back to list

Carbon Steel Pipe-The Origins of Stainless Steel

As manufacturers and builders, we know how to make things, because that’s our job. But do you know where the materials you rely on to create your products come from? For instance, the many different grades of stainless steel we sell don’t come out of the ground that way. They must go through an intense alloying process in order to ensure every inch of metal you use in your production process can meet the highest standards for performance, durability, and reliability.

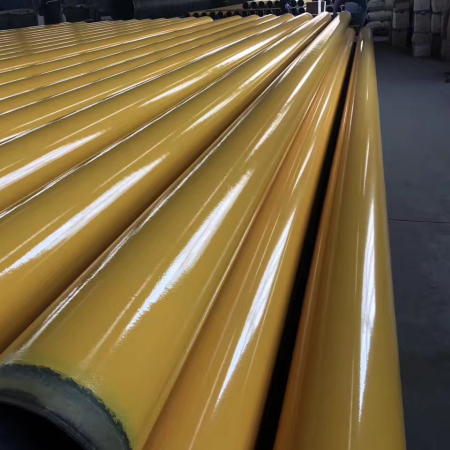

3LPE Coated Steel Pipe used in pipeline transportation

Understanding how your materials get produced can help ensure you get just the right metal for any particular job. And to help you make the perfect selection, Clinton Aluminum’s team of technical professionals are ready to assist you through your entire production process. Contact us today to learn how we can help.

The Origins of Stainless Steel

It may seem like the burgeoning number of very specialized high-performance stainless steel and aluminum alloys is a very recent phenomenon, given the fact that stainless steel has only been around for about a century. But the reality is that humans have been alloying metals for several thousand years. In fact, it is one of the most important factors in the advance of civilization.

The first metal alloys to be discovered were bronze, a combination of copper and tin, and brass, a combination of copper and zinc. But it was the development of carbon steel, which was to usher in the Iron Age of prehistory, that would really spur human progress forward.

Until this point in history, iron was not very widely popular. This was because pure iron is actually soft and too ductile. The process of adding carbon, the necessary ingredient to create steel, hardens the metal by filling in the crystal structure and lowering the number of dislocations at the molecular level.

By comparison, stainless steel was a much more recent development. Over many decades in the 1800’s, metallurgists looked into the possibility of iron-chromium alloys, which seemed to offer much greater durability and corrosion resistance than traditional carbon steel. Once they succeeded in solving the problem of how to economically and efficiently produce stainless steel, it quickly became a must have material for a host of industries.

Stainless steel can range from 10 to 30 percent chromium content. It also requires a lower carbon content than carbon steel. These are the primary necessities for stainless steel, but different alloys can include the addition of many other elements, such as nickel, aluminum, molybdenum, titanium, copper, nitrogen, niobium, sulfur, phosphorus, and selenium. The various ways in which they are combined can lead to a tremendous diversity in the many stainless-steel grades available on the market.

What Are the classes of Stainless Steel?

There are five recognized classes or families of stainless steels. Typically, when you are picking out an alloy, you’ll select one of these five classes. The most common of them is called austenitic stainless steel. These are alloys that are primarily made up of chromium and nickel. They are non-magnetic and have strong corrosion resistance. The austenitic class includes the 200 and 300 series of grades.

The ferritic class of stainless steels contain less chromium and nickel than austenitic steels, but have molybdenum, aluminum, or titanium added as well. This combination results in increased ductility and resistance to stress corrosion cracking. They are comprised of alloys in the 400 series.

The next class is martensitic stainless steel. These alloys also fall into the 400 series, meaning there is a lot of similarity between these and ferritic stainless steels. At the molecular level, they can be distinguished by the fact that martensitic steels have increased carbon content and reduced chromium. This means unlike the two classes already mentioned, these steels can more easily be hardened via heat treatment.

Precipitation-hardening stainless steel contains aluminum, copper, and titanium as alloying agents. It gets its name from the solution and aging heat treatment that it undergoes, giving these alloys a higher tensile strength than other classes.

Finally, the most recent class is known as duplex stainless steel. This class combines properties of ferritic and austenitic alloys. The combination of 24% chromium and 5% nickel leads to increased yield strength and improved stress corrosion resistance. This is especially true in chloride environments.

How is Stainless Steel Produced?

To create stainless steel, first, the raw materials (the iron and alloying agents) must be combined. This is done by heating everything in an electric furnace. As part of this process, some of the carbon content must be extracted by refining it in a vessel. This happens via an argon-oxygen decarburization process, which injects oxygen and argon gas into the molten steel.

Following the melting, the steel can be cast into a variety of forms. These shapes might be blooms, billets, slabs, rods, or tubes. The steel then undergoes a hot-rolling process, which can produce the plate, sheet, wire, or other forms that are required by manufacturers.

Next, the steel must be heat-treated or annealed, which alters the physical and chemical properties. The process involves heating the metal until it is glowing and then letting it cool, either naturally or by quenching it in water. This will boost the ductility and reduce the hardness, which in turn improves how workable the material is. The type of annealing is determined by which class of stainless steel you are dealing with.

Following this process, the metal must be descaled, due to the buildup that occurs during the annealing. Methods include pickling or electro cleaning. The metal is then ready for cutting and finishing.

Summary

Having a thorough knowledge of what goes into preparing stainless steel alloys before they end up in a wholesaler’s warehouse makes it much easier for manufacturers to get the right material for the job. To make your selection process even easier, you can consult with one of the friendly and knowledgeable technical professionals at Clinton Aluminum.

We pride ourselves in helping our clients navigate every step of the production process. To learn more about how we can help your business succeed, contact us today.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024