Gen . 25, 2024 15:43 Back to list

Stainless steel-is stainless steel magnetic

Stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES) and rustless steel, is an alloy of iron that is resistant to rusting and corrosion. It contains at least 10.5% chromium and usually nickel, as well as 0.2 to 2.11% carbon. Stainless steel's resistance to corrosion results from the chromium, which forms a passive film that can protect the material and self-heal in the presence of oxygen.[1]: 3

The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products.

The biological cleanability of stainless steel is superior to both aluminium and copper, and comparable to glass.[2] Its cleanability, strength, and corrosion resistance have prompted the use of stainless steel in pharmaceutical and food processing plants.[3]

Different types of stainless steel are labeled with an AISI three-digit number.[4] The ISO 15510 standard lists the chemical compositions of stainless steels of the specifications in existing ISO, ASTM, EN, JIS, and GB standards in a useful interchange table.[5]

Properties[edit]

Corrosion resistance[edit]

Although stainless steel does rust, this only affects the outer few layers of atoms, its chromium content shielding deeper layers from oxidation.

The addition of nitrogen also improves resistance to pitting corrosion and increases mechanical strength.[6] Thus, there are numerous grades of stainless steel with varying chromium and molybdenum contents to suit the environment the alloy must endure.[7] Corrosion resistance can be increased further by the following means:

- increasing chromium content to more than 11%[6]

- adding nickel to at least 8%[6]

- adding molybdenum (which also improves resistance to pitting corrosion)[6]

Strength[edit]

The most common type of stainless steel, 304, has a tensile yield strength around 30,000 psi (210 MPa) in the annealed condition. It can be strengthened by cold working to a strength of 153,000 psi (1,050 MPa) in the full-hard condition.

The strongest commonly available stainless steels are precipitation hardening alloys such as 17-4 PH and Custom 465. These can be heat treated to have tensile yield strengths up to 251,000 psi (1,730 MPa).[8]

Melting point[edit]

Stainless steel is a steel, and as such its melting point is near that of ordinary steel, and much higher than the melting points of aluminium or copper. As with most alloys, the melting point of stainless steel is expressed in the form of a range of temperatures, and not a single temperature.[9] This temperature range goes from 1,400 to 1,530 °C (2,550 to 2,790 °F; 1,670 to 1,800 K; 3,010 to 3,250 °R)[10] depending on the specific consistency of the alloy in question.

Conductivity[edit]

Like steel, stainless steels are relatively poor conductors of electricity, with significantly lower electrical conductivities than copper. In particular, the non-electrical contact resistance (ECR) of stainless steel arises as a result of the dense protective oxide layer and limits its functionality in applications as electrical connectors.[11] Copper alloys and nickel-coated connectors tend to exhibit lower ECR values and are preferred materials for such applications. Nevertheless, stainless steel connectors are employed in situations where ECR poses a lower design criteria and corrosion resistance is required, for example in high temperatures and oxidizing environments.[12]

Magnetism[edit]

Martensitic, duplex and ferritic stainless steels are magnetic, while austenitic stainless steel is usually non-magnetic.[13] Ferritic steel owes its magnetism to its body-centered cubic crystal structure, in which iron atoms are arranged in cubes (with one iron atom at each corner) and an additional iron atom in the center. This central iron atom is responsible for ferritic steel's magnetic properties. This arrangement also limits the amount of carbon the steel can absorb to around 0.025%.[14] Grades with low coercive field have been developed for electro-valves used in household appliances and for injection systems in internal combustion engines. Some applications require non-magnetic materials, such as magnetic resonance imaging.[citation needed] Austenitic stainless steels, which are usually non-magnetic, can be made slightly magnetic through work hardening. Sometimes, if austenitic steel is bent or cut, magnetism occurs along the edge of the stainless steel because the crystal structure rearranges itself.[15]

Wear[edit]

Galling, sometimes called cold welding, is a form of severe adhesive wear, which can occur when two metal surfaces are in relative motion to each other and under heavy pressure. Austenitic stainless steel fasteners are particularly susceptible to thread galling, though other alloys that self-generate a protective oxide surface film, such as aluminum and titanium, are also susceptible. Under high contact-force sliding, this oxide can be deformed, broken, and removed from parts of the component, exposing the bare reactive metal. When the two surfaces are of the same material, these exposed surfaces can easily fuse. Separation of the two surfaces can result in surface tearing and even complete seizure of metal components or fasteners.[17][18] Galling can be mitigated by the use of dissimilar materials (bronze against stainless steel) or using different stainless steels (martensitic against austenitic). Additionally, threaded joints may be lubricated to provide a film between the two parts and prevent galling. Nitronic 60, made by selective alloying with manganese, silicon, and nitrogen, has demonstrated a reduced tendency to gall.[18]

History

The invention of stainless steel followed a series of scientific developments, starting in 1798 when chromium was first shown to the French Academy by Louis Vauquelin. In the early 1800s, British scientists James Stoddart, Michael Faraday, and Robert Mallet observed the resistance of chromium-iron alloys ("chromium steels") to oxidizing agents. Robert Bunsen discovered chromium's resistance to strong acids. The corrosion resistance of iron-chromium alloys may have been first recognized in 1821 by Pierre Berthier, who noted their resistance against attack by some acids and suggested their use in cutlery.[21]

In the 1840s, both Britain's Sheffield steelmakers and then Krupp of Germany were producing chromium steel with the latter employing it for cannons in the 1850s.[22] In 1861, Robert Forester Mushet took out a patent on chromium steel in Britain.[23]

These events led to the first American production of chromium-containing steel by J. Baur of the Chrome Steel Works of Brooklyn for the construction of bridges. A US patent for the product was issued in 1869.[24]: 2261 [a] This was followed with recognition of the corrosion resistance of chromium alloys by Englishmen John T. Woods and John Clark, who noted ranges of chromium from 5–30%, with added tungsten and "medium carbon". They pursued the commercial value of the innovation via a British patent for "Weather-Resistant Alloys".[24]: 261, 11 [25][full citation needed]

In the late 1890s, German chemist Hans Goldschmidt developed an aluminothermic (thermite) process for producing carbon-free chromium.[26] Between 1904 and 1911, several researchers, particularly Leon Guillet of France, prepared alloys that would be considered stainless steel today.[26][27]

In 1908, the Essen firm Friedrich Krupp Germaniawerft built the 366-ton sailing yacht Germania featuring a chrome-nickel steel hull, in Germany. In 1911, Philip Monnartz reported on the relationship between chromium content and corrosion resistance.[28] On 17 October 1912, Krupp engineers Benno Strauss and Eduard Maurer patented as Nirosta the austenitic stainless steel[29][30][31][28] known today as 18/8 or AISI type 304.[32]

Similar developments were taking place in the United States, where Christian Dantsizen of General Electric[32] and Frederick Becket (1875–1942) at Union Carbide were industrializing ferritic stainless steel.[33] In 1912, Elwood Haynes applied for a US patent on a martensitic stainless steel alloy, which was not granted until 1919.[34]

Harry Brearley[edit]

While seeking a corrosion-resistant alloy for gun barrels in 1912, Harry Brearley of the Brown-Firth research laboratory in Sheffield, England, discovered and subsequently industrialized a martensitic stainless steel alloy, today known as AISI type 420.[32] The discovery was announced two years later in a January 1915 newspaper article in The New York Times.[20]

The metal was later marketed under the "Staybrite" brand by Firth Vickers in England and was used for the new entrance canopy for the Savoy Hotel in London in 1929.[35] Brearley applied for a US patent during 1915 only to find that Haynes had already registered one. Brearley and Haynes pooled their funding and, with a group of investors, formed the American Stainless Steel Corporation, with headquarters in Pittsburgh, Pennsylvania.[24]: 360

Rustless steel[edit]

Brearley initially called his new alloy "rustless steel". The alloy was sold in the US under different brand names like "Allegheny metal" and "Nirosta steel". Even within the metallurgy industry, the name remained unsettled; in 1921, one trade journal called it "unstainable steel".[36] Brearley worked with a local cutlery manufacturer, who gave it the name "stainless steel".[37] As late as 1932, Ford Motor Company continued calling the alloy "rustless steel" in automobile promotional materials.[38]

In 1929, before the Great Depression, over 25,000 tons of stainless steel were manufactured and sold in the US annually.[39]

Major technological advances in the 1950s and 1960s allowed the production of large tonnages at an affordable cost:

- AOD process (argon oxygen decarburization), for the removal of carbon and sulfur

- Continuous casting and hot strip rolling[40]

- The Z-Mill, or Sendzimir cold rolling mill[41][42]

- The Creusot-Loire Uddeholm (CLU) and related processes which use steam instead of some or all of the argon[43]

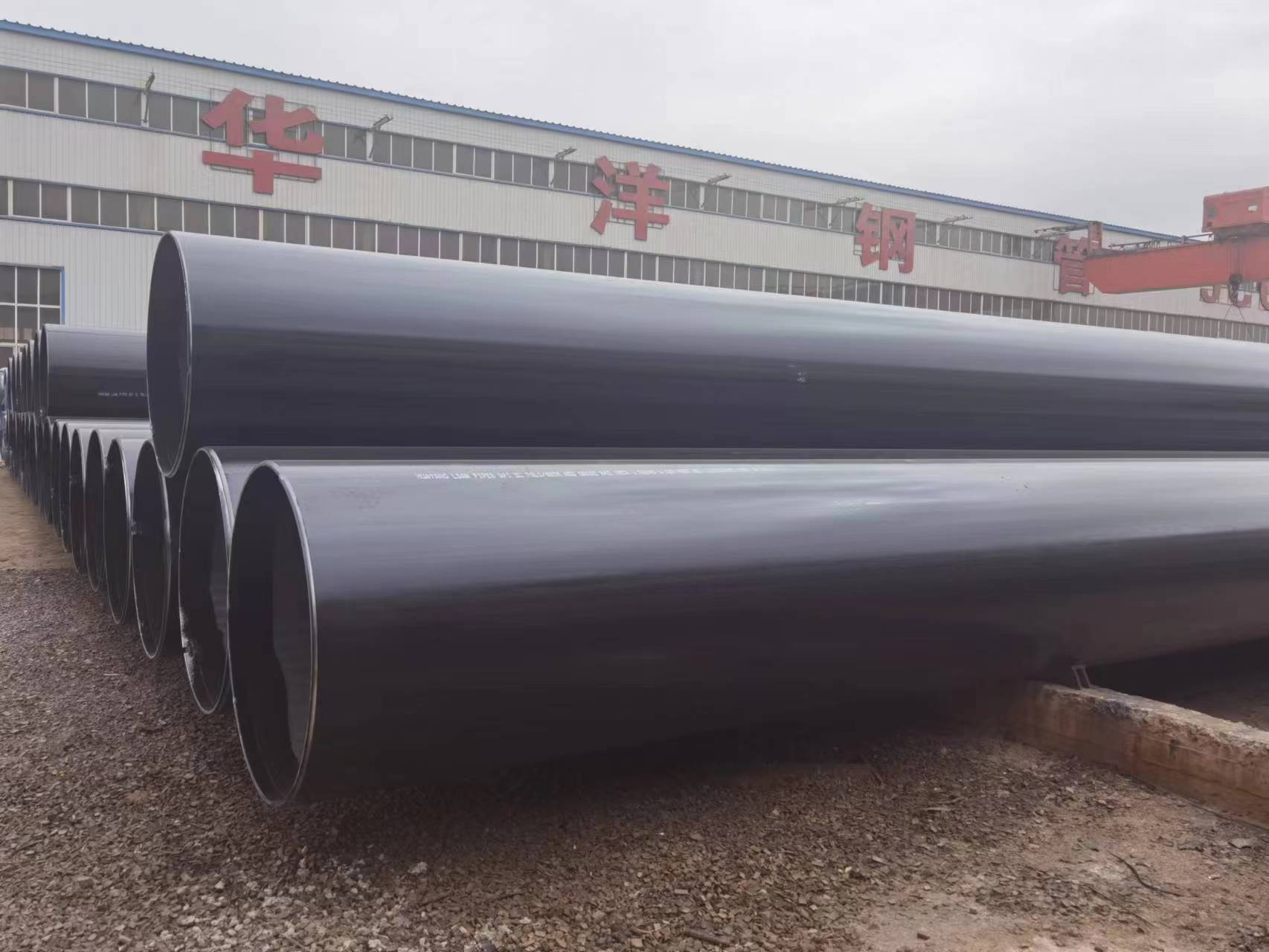

EFW Steel Pipe

Types[edit]

Stainless steel is classified into five main families that are primarily differentiated by their crystalline structure:

- austenitic

- ferritic

- martensitic

- duplex

- precipitation hardening

Austenitic[edit]

Austenitic stainless steel[44][45] is the largest family of stainless steels, making up about two-thirds of all stainless steel production.[46] They possess an austenitic microstructure, which is a face-centered cubic crystal structure.[47] This microstructure is achieved by alloying steel with sufficient nickel and/or manganese and nitrogen to maintain an austenitic microstructure at all temperatures, ranging from the cryogenic region to the melting point.[47] Thus, austenitic stainless steels are not hardenable by heat treatment since they possess the same microstructure at all temperatures.[47]

However, "forming temperature is an essential factor for metastable austenitic stainless steel (M-ASS) products to accommodate microstructures and cryogenic mechanical performance. ... Metastable austenitic stainless steels (M-ASSs) are widely used in manufacturing cryogenic pressure vessels (CPVs), owing to their high cryogenic toughness, ductility, strength, corrosion-resistance, and economy."[48]

Cryogenic cold-forming of austenitic stainless steel is an extension of the heating-quenching-tempering cycle, where the final temperature of the material before full-load use is taken down to a cryogenic temperature range. This can remove residual stresses and improve wear resistance.[49]

Austenitic stainless steel sub-groups, 200 series and 300 series:

- 200 series[50] are chromium-manganese-nickel alloys that maximize the use of manganese and nitrogen to minimize the use of nickel. Due to their nitrogen addition, they possess approximately 50% higher yield strength than 300-series stainless sheets of steel.

- Type 201 is hardenable through cold working.[51]

- Type 202 is general-purpose stainless steel. Decreasing nickel content and increasing manganese results in weak corrosion resistance.

- 300 series are chromium-nickel alloys that achieve their austenitic microstructure almost exclusively by nickel alloying; some very highly alloyed grades include some nitrogen to reduce nickel requirements. 300 series is the largest group and the most widely used.

- Type 304: The most common is type 304, also known as 18/8 and 18/10 for its composition of 18% chromium and 8% or 10% nickel, respectively.

- Type 316: The second most common austenitic stainless steel is type 316. The addition of 2% molybdenum provides greater resistance to acids and localized corrosion caused by chloride ions. Low-carbon versions, such as 316L or 304L, have carbon contents below 0.03% and are used to avoid corrosion problems caused by welding.[52]

Ferritic[edit]

Ferritic stainless steels possess a ferrite microstructure like carbon steel, which is a body-centered cubic crystal structure, and contain between 10.5% and 27% chromium with very little or no nickel. This microstructure is present at all temperatures due to the chromium addition, so they are not capable of being hardened by heat treatment. They cannot be strengthened by cold work to the same degree as austenitic stainless steels. They are magnetic. Additions of niobium (Nb), titanium (Ti), and zirconium (Zr) to type 430 allow good weldability. Due to the near-absence of nickel, they are less expensive than austenitic steels and are present in many products, which include:

- Automobile exhaust pipes (type 409 and 409 Cb[b] are used in North America; stabilized grades type 439 and 441 are used in Europe)[53]

- Architectural and structural applications (type 430, which contains 17% Cr)[54]

- Building components, such as slate hooks, roofing, and chimney ducts

- Power plates in solid oxide fuel cells operating at temperatures around 700 °C (1,300 °F) (high-chromium ferritics containing 22% Cr)[55]

Martensitic[edit]

Martensitic stainless steels have a body-centered cubic crystal structure, and offer a wide range of properties and are used as stainless engineering steels, stainless tool steels, and creep-resistant steels. They are magnetic, and not as corrosion-resistant as ferritic and austenitic stainless steels due to their low chromium content. They fall into four categories (with some overlap):[56]

- Fe-Cr-C grades. These were the first grades used and are still widely used in engineering and wear-resistant applications.

- Fe-Cr-Ni-C grades. Some carbon is replaced by nickel. They offer higher toughness and higher corrosion resistance. Grade EN 1.4303 (Casting grade CA6NM) with 13% Cr and 4% Ni is used for most Pelton, Kaplan, and Francis turbines in hydroelectric power plants[57] because it has good casting properties, good weldability and good resistance to cavitation erosion.

- Precipitation hardening grades. Grade EN 1.4542 (also known as 17-4 PH), the best-known grade, combines martensitic hardening and precipitation hardening. It achieves high strength and good toughness and is used in aerospace among other applications.

- Creep-resisting grades. Small additions of niobium, vanadium, boron, and cobalt increase the strength and creep resistance up to about 650 °C (1,200 °F).

Martensitic stainless steels can be heat treated to provide better mechanical properties. The heat treatment typically involves three steps:[58]

- Austenitizing, in which the steel is heated to a temperature in the range 980–1,050 °C (1,800–1,920 °F), depending on grade. The resulting austenite has a face-centered cubic crystal structure.

- Quenching. The austenite is transformed into martensite, a hard body-centered tetragonal crystal structure. The quenched martensite is very hard and too brittle for most applications. Some residual austenite may remain.

- Tempering. Martensite is heated to around 500 °C (930 °F), held at temperature, then air-cooled. Higher tempering temperatures decrease yield strength and ultimate tensile strength but increase the elongation and impact resistance.

Replacing some carbon in martensitic stainless steels by nitrogen is a recent development.[when?] The limited solubility of nitrogen is increased by the pressure electroslag refining (PESR) process, in which melting is carried out under high nitrogen pressure. Steel containing up to 0.4% nitrogen has been achieved, leading to higher hardness and strength and higher corrosion resistance. As PESR is expensive, lower but significant nitrogen contents have been achieved using the standard AOD process.[59][60][61][62][63]

Duplex[edit]

Duplex stainless steels have a mixed microstructure of austenite and ferrite, the ideal ratio being a 50:50 mix, though commercial alloys may have ratios of 40:60. They are characterized by higher chromium (19–32%) and molybdenum (up to 5%) and lower nickel contents than austenitic stainless steels. Duplex stainless steels have roughly twice the yield strength of austenitic stainless steel. Their mixed microstructure provides improved resistance to chloride stress corrosion cracking in comparison to austenitic stainless steel types 304 and 316. Duplex grades are usually divided into three sub-groups based on their corrosion resistance: lean duplex, standard duplex, and super duplex. The properties of duplex stainless steels are achieved with an overall lower alloy content than similar-performing super-austenitic grades, making their use cost-effective for many applications. The pulp and paper industry was one of the first to extensively use duplex stainless steel. Today, the oil and gas industry is the largest user and has pushed for more corrosion resistant grades, leading to the development of super duplex and hyper duplex grades. More recently, the less expensive (and slightly less corrosion-resistant) lean duplex has been developed, chiefly for structural applications in building and construction (concrete reinforcing bars, plates for bridges, coastal works) and in the water industry.

Precipitation hardening[edit]

Precipitation hardening stainless steels have corrosion resistance comparable to austenitic varieties, but can be precipitation hardened to even higher strengths than other martensitic grades. There are three types of precipitation hardening stainless steels:[64]

- Martensitic 17-4 PH (AISI 630 EN 1.4542) contains about 17% Cr, 4% Ni, 4% Cu, and 0.3% Nb.

Solution treatment at about 1,040 °C (1,900 °F) followed by quenching results in a relatively ductile martensitic structure. Subsequent aging treatment at 475 °C (887 °F) precipitates Nb and Cu-rich phases that increase the strength up to above 1000 MPa yield strength. This outstanding strength level is used in high-tech applications such as aerospace (usually after remelting to eliminate non-metallic inclusions, which increases fatigue life). Another major advantage of this steel is that aging, unlike tempering treatments, is carried out at a temperature that can be applied to (nearly) finished parts without distortion and discoloration.

- Semi-austenitic 17-7 PH (AISI 631 EN 1.4568) contains about 17% Cr, 7.2% Ni, and 1.2% Al.

Typical heat treatment involves solution treatment and quenching. At this point, the structure remains austenitic. Martensitic transformation is then obtained either by a cryogenic treatment at −75 °C (−103 °F) or by severe cold work (over 70% deformation, usually by cold rolling or wire drawing). Aging at 510 °C (950 °F) — which precipitates the Ni3Al intermetallic phase—is carried out as above on nearly finished parts. Yield stress levels above 1400 MPa are then reached.

- Austenitic A286[65](ASTM 660 EN 1.4980) contains about Cr 15%, Ni 25%, Ti 2.1%, Mo 1.2%, V 1.3%, and B 0.005%.

The structure remains austenitic at all temperatures.

Typical heat treatment involves solution treatment and quenching, followed by aging at 715 °C (1,319 °F). Aging forms Ni3Ti precipitates and increases the yield strength to about 650 MPa (94 ksi) at room temperature. Unlike the above grades, the mechanical properties and creep resistance of this steel remain very good at temperatures up to 700 °C (1,300 °F). As a result, A286 is classified as an Fe-based superalloy, used in jet engines, gas turbines, and turbo parts.

-

High Quality Mild Steel Pipe Manufacturers in China for Exporting Premium Industrial Solutions

NewsAug.01,2024

-

Exploring Key Characteristics of Wholesale API Steel Pipes for Your Business Needs

NewsAug.01,2024

-

Current Wholesale Prices for ERW Steel Pipes in the Market Right Now

NewsAug.01,2024

-

Exploring the Diverse Applications and Benefits of China Round Steel Pipes in Construction and Industry

NewsAug.01,2024

-

Top Quality API 5L ERW Steel Pipe Manufacturer Offering Reliable and Durable Solutions for Your Needs

NewsAug.01,2024

-

Reliable Supplier of Premium Quality Concrete Pipes for Durable Construction Projects

NewsAug.01,2024