Blog

-

TUBI IN ACCIAIO SENZA SALDATURA OTTENUTI PER ESTRUSIONE A CALDO-ACCIAIO SENZA SALDATURA-erw pipe

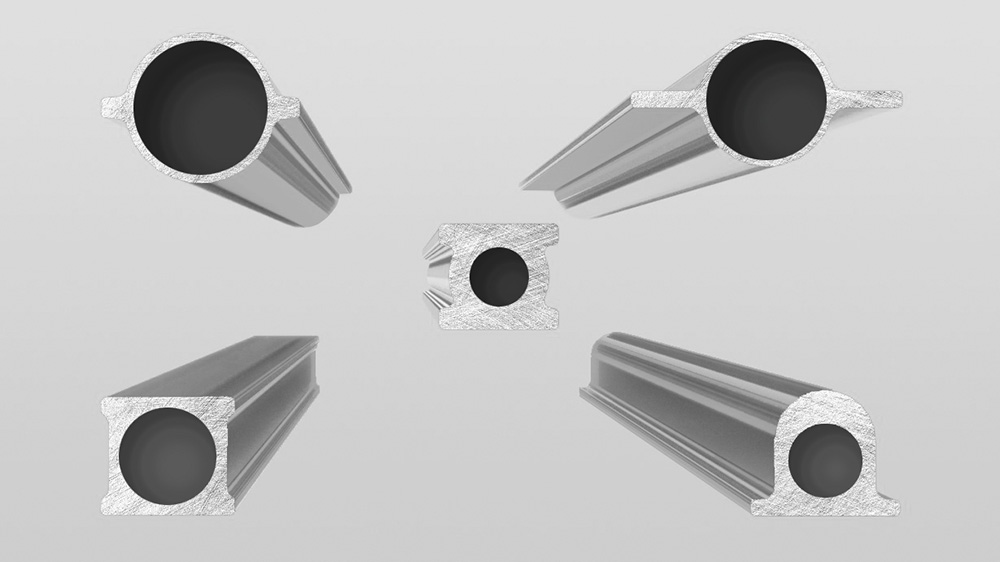

I tubi in acciaio senza saldatura ottenuti per estrusione a caldo sono il risultato di un processo produttivo in cui la forza agente è la compressione. Nell’estrusione a caldo, le billette di acciaio vengono spinte attraverso le cosiddette “luci di passaggio” che vengono sagomate e disposte su appositi utensili, detti matrici, in modo da ottenere la forma desiderata. Questo tipo di lavorazione avviene ad alte temperature per ridurre le forze necessarie e operare più facilmente su materiali che, per loro natura, non sarebbero particolarmente duttili se lavorati a temperatura ambiente.Per saperne di più -

TUBI IN ACCIAIO SENZA SALDATURA OTTENUTI PER ESTRUSIONE A CALDO-Tubo in acciaio inox

I tubi in acciaio senza saldatura ottenuti per estrusione a caldo sono il risultato di un processo produttivo in cui la forza agente è la compressione. Nell’estrusione a caldo, le billette di acciaio vengono spinte attraverso le cosiddette “luci di passaggio” che vengono sagomate e disposte su appositi utensili, detti matrici, in modo da ottenere la forma desiderata. Questo tipo di lavorazione avviene ad alte temperature per ridurre le forze necessarie e operare più facilmente su materiali che, per loro natura, non sarebbero particolarmente duttili se lavorati a temperatura ambiente.Per saperne di più -

Seamless steel pipes-ERW Steel Pipe

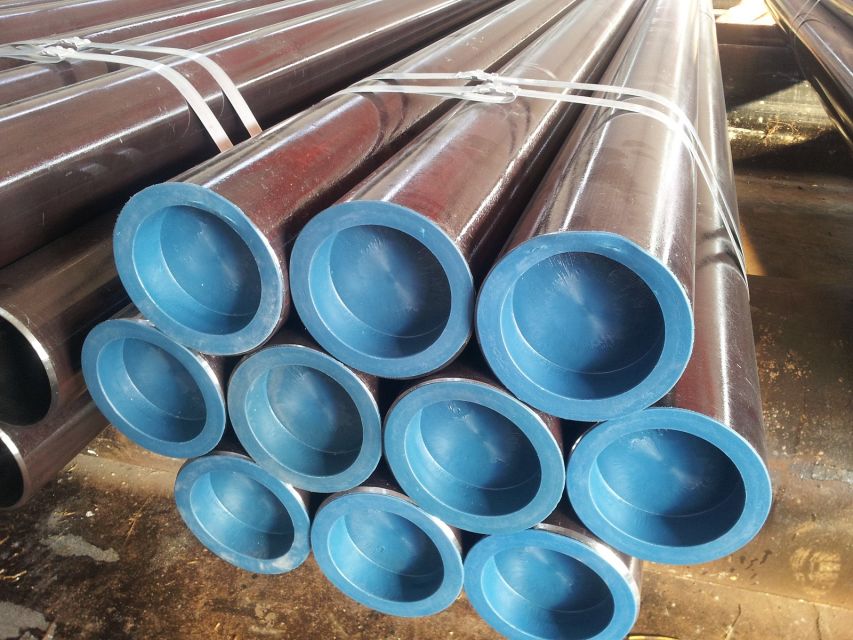

Seamless steel pipes are produced by piercing a solid billet of steel to form a hollow tube. The billet is heated to a temperature that allows it to be easily pierced by a piercing mill. The mill contains a mandrel, which is a cylindrical tool that supports the inside of the tube during the piercing process.Once the billet is pierced, it is rolled and stretched to achieve the desired shape and size of the tube. This process is known as the extrusion process. The extrusion process can produce seamless pipes of various sizes and thicknesses, making them suitable for a range of applications.The main advantage of seamless pipes is that they have a smooth surface finish, which is essential for industries such as water supply, where cleanliness is crucial. Seamless pipes are also stronger and more durable than welded pipes, making them suitable for applications where high pressure and high temperatures are involved, such as in the oil and gas industry.Per saperne di più -

how are steel tubes made-Welded Steel Pipe

Steel tube (and Steel Pipe) has evolved over history. Specifically, metal tube has been around since around 3000 BC. In fact, Egyptians made the first metal pipe from copper.As Early as 2500 BC Chinese used bamboo pipe as a way to transport gasAs early as 2500 BC, Chinese used bamboo pipe as a way to transport natural gas to light Peking, their capital. Rome and Persia created aqueducts to bring water to city centers for bathing, washing and drinking.Furthermore, pipe (or tubing) is made with many different materials and methods. Hollowed stone, fired clay, bamboo, palm, redwood, lead, bronze, copper, and rubber are just some of the materials that makeup tubing.In the mid-1800’s the modern steel industry was bolstered with the Bessemer process. The Bessemer process represented the first inexpensive method for mass production of steel pipe. Subsequently, seamless tube was born in 1895. Quickly followed by manufacturing of auto, bicycle, and machinery for oil production which began in full force.Per saperne di più -

HOW THESE PIPES ARE MADE?-erw carbon steel pipe

Steel pipes are cylindrical steel tubes that are used in the manufacture and infrastructure of several different styles. They are the most used steel industry product. The key use of pipe is in the underground movement of liquid or gas, including oil, gas and water. However in the development and construction process pipes of different sizes are used. The narrow steel pipe that operates the cooling system in refrigerators is a typical example of household development. Building uses heating and plumbing tubing. It is possible to create structures using steel pipes of various sizes like handrails, bike racks or pipe pads.The pioneer of steel pipe fabricators is believed to be William Murdoch. In 1815 he mixed barrels of muskets with a burning system of coal lamps. In his revolutionary piping method, Murdoch used coal gas to be brought to lamps on London’s streets.Since the 1800’s, significant advances have been made in steel pipes technology, including the advancement of production processes, development of applications for their use and the development and qualification of regulations and standards.Per saperne di più -

lsaw steel pipe-erw carbon steel pipe

I tubi in acciaio di alta qualità sono prodotti mediante tre (3) processi di produzione: senza saldatura, LSAW (saldatura ad arco sommerso con cucitura longitudinale) ed ERW (saldatura a resistenza elettrica). I tubi LSAW ed ERW sono molto apprezzati per i loro numerosi campi di applicazione. Sono estremamente utilizzati in soluzioni e sistemi di fondazione, costruzioni marine, costruzioni strutturali e diverse applicazioni in progetti idrici, industria petrolchimica, chimica ed energetica, irrigazione agricola, edilizia urbana e altro ancora.Per saperne di più -

How lsaw steel pipe made?-lsaw steel pipe

LSAW steel pipe (Longitudinally Submerged Arc Welding abbreviated as LSAW) is a professional expression term for LSAW steel pipe. It uses a single medium and thick plate as the raw material, and the steel plate is pressed (rolled) into a tube blank in a mold or a forming machine. The pipe is produced by submerged arc welding and expanded diameter.UOE LSAW pipe forming process:The three main forming processes of UOE LSAW steel pipe forming process include: steel plate pre-bending, U forming and O forming. Each process adopts a dedicated forming press to complete the three processes of pre-bending the edge of the steel plate, U forming and O forming in sequence to deform the steel plate into a circular tube.JCOE LSAW pipe forming process:Forming: After several steps of stamping on the JCO forming machine, first half of the steel plate is pressed into a "J" shape, then the other half of the steel plate is pressed into a "J" to form a "C" shape, and finally pressurized from the middle to form An open "O"-shaped tube blank is formed.Per saperne di più -

Tube And Pipe Compared-lsaw steel pipe

Steel tube (and Steel Pipe) has evolved over history. Specifically, metal tube has been around since around 3000 BC. In fact, Egyptians made the first metal pipe from copper.As Early as 2500 BC Chinese used bamboo pipe as a way to transport gasAs early as 2500 BC, Chinese used bamboo pipe as a way to transport natural gas to light Peking, their capital. Rome and Persia created aqueducts to bring water to city centers for bathing, washing and drinking.Furthermore, pipe (or tubing) is made with many different materials and methods. Hollowed stone, fired clay, bamboo, palm, redwood, lead, bronze, copper, and rubber are just some of the materials that makeup tubing.In the mid-1800’s the modern steel industry was bolstered with the Bessemer process. The Bessemer process represented the first inexpensive method for mass production of steel pipe. Subsequently, seamless tube was born in 1895. Quickly followed by manufacturing of auto, bicycle, and machinery for oil production which began in full force.Per saperne di più -

COME SONO FATTI QUESTI TUBI?-tubo in acciaio lsaw

Steel pipes are cylindrical steel tubes that are used in the manufacture and infrastructure of several different styles. They are the most used steel industry product. The key use of pipe is in the underground movement of liquid or gas, including oil, gas and water. However in the development and construction process pipes of different sizes are used. The narrow steel pipe that operates the cooling system in refrigerators is a typical example of household development. Building uses heating and plumbing tubing. It is possible to create structures using steel pipes of various sizes like handrails, bike racks or pipe pads.The pioneer of steel pipe fabricators is believed to be William Murdoch. In 1815 he mixed barrels of muskets with a burning system of coal lamps. In his revolutionary piping method, Murdoch used coal gas to be brought to lamps on London’s streets.Since the 1800’s, significant advances have been made in steel pipes technology, including the advancement of production processes, development of applications for their use and the development and qualification of regulations and standards.Per saperne di più