Blogo

-

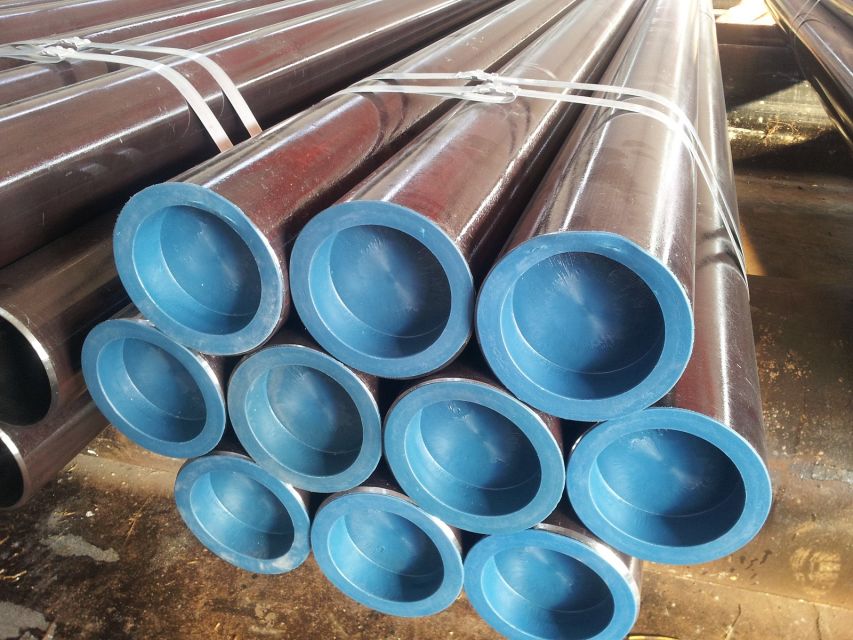

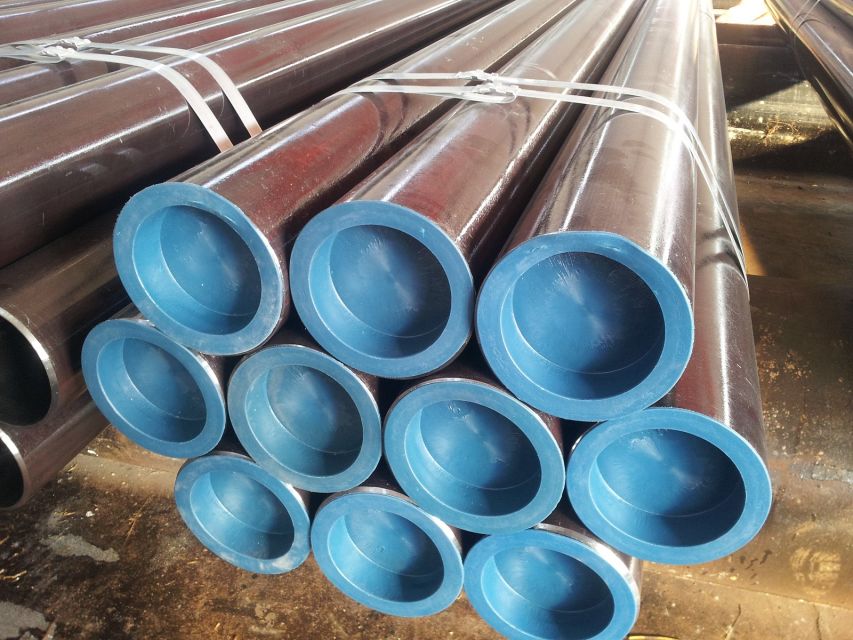

What is Carbon Steel Pipe?

Carbon steel pipe & tube is also called CS pipe. Carbon steel pipes are made of steel ingots or solid round steels through perforation into capillary tubes, which are then hot-rolled, cold-rolled or cold-drawn. Due to its strength and ability to withstand pressure, carbon steel pipes are used in a variety of heavy industries such as infrastructure, ships, stills, and fertilizer equipment. Carbon steel pipe plays an important role in my country's steel pipe industry.Legu pli -

ERW Steel Pipe -The Main Advantages of ERW Steel Pipe You Need To Know

ERW pipes, also known as Electric Resistance Welded pipes are manufactured through a welding process in which the edges of the steel strip or plate are heated and fused together under pressure, creating a seamless joint. The welding is performed by passing an electric current through the strip or plate, which generates heat and forms the weld.These pipes have revolutionized the way we transport fluids and gases with their electrifying energy, impressive strength, and unbeatable efficiency, ERW pipes are the superstars of the piping universe, ready to take your infrastructure to new heights. Known for their high strength, durability, and cost-effectiveness, they are widely used in various industries, including oil and gas, construction, water supply, and plumbing. Furthermore, these pipes come in different sizes and thicknesses to meet specific application requirements.Legu pli -

ERW Steel Pipe-Difference between erw and seamless pipe

There are two benefits of using a seamless pipe. First, the working pressure capacity of a seamless pipe is 20% higher than an erw pipe, because, unlike erw pipes, the application of a higher pressure level will not cause the pipe to fail or burst. And the other, more popular reason for choosing a seamless pipe is that they are not vulnerable to intergranular corrosion. As opposed to seamless pipes, the seam line on welded pipes, in particular, the HAZ or heat affected weld zone gets affected at the grain boundary due to sensitization. This fosters intergranular corrosion, thereby weakening the erw pipe.Legu pli -

ERW Steel Pipe-ERW vs MS Pipes – What’s the Difference

The manufacturing process is the primary difference between the ERW and MS pipes. ERW pipes are made from hot-rolled steel coils and are formed through electrical resistance welding. On the other hand, MS pipes are made from mild steel and are formed by rolling the steel to its required thickness and then welding the seams.Legu pli -

ERW Steel Pipe-Differences Between ERW and LSAW Steel Pipe

Straight seam welded steel pipes are divided into high frequency resistance welding and submerged arc welding according to the welding process. Straight seam submerged arc welding is referred to as LSAW, and longitudinal high frequency resistance welding is referred to as ERW.Compared with submerged arc welding, high frequency electric resistance welded steel pipes (ERW steel pipes) do not add any welding materials during the welding process in the ERW process, and the weld formation does not undergo a thermal melting state, but the weld metal undergoes a recrystallization process. Therefore, the formed weld seam is completely consistent with the chemical composition of the base metal. After the steel pipe is welded, it is annealed to produce the cold working internal stress and welding internal stress. Therefore, the comprehensive mechanical properties of the ERW steel pipe are better.Legu pli -

ERW Steel Pipe -Kio estas ERW-Pipoj?

ERW-pipoj estas faritaj el strioj el ŝtalo kiuj estas formitaj en cilindran formon kaj tiam velditaj kune. La veldo estas kreita aplikante premon kaj elektran kurenton al la ŝtalo, kiu fandas la randojn de la ŝtalo kaj kunfandas ilin. ERW-pipoj estas produktitaj en diversaj grandecoj kaj dikecoj por plenumi la postulojn de malsamaj aplikoj.Unu el la ĉefaj avantaĝoj de ERW-pipoj estas ilia kostefikeco. Kompare kun aliaj specoj de pipoj, kiel senjuntaj pipoj aŭ spiral-velditaj pipoj, ERW-pipoj estas malpli multekostaj por fabriki kaj pli facile produkti en grandaj kvantoj. Ĉi tio igas ilin populara elekto por aplikoj, kiuj postulas grandan volumon da tuboj.Legu pli -

ERW Steel Pipe -WHAT IS ERW STEEL TUBE?

ERW, or Electric Resistance Welded steel, refers to the manufacturing method whereby Round E.R.W Steel Tube, or Electric Resistance Welded Steel Pipe has its steel edges melted and welded to form a consistent cylindrical shape. Heat and pressure are combined to join the steel sheet to give you a very lightweight and easy to work with tubing for an array of engineering and construction requirements from fencing to scaffolding. It can even be used in domestic or commercial settings for a vast array of possibilities.The end product exists between welded steel pipes and seamless materials and is therefore smooth and more consistent in surface texture without an obvious weld seam. You'll get a really consistent edge that's easily formed, durable and easy to work, weld, cut to size and drill.Legu pli -

Welded Steel Pipe-Welded vs. seamless steel pipe

An advantage of ERW pipe is that no fusion metals are used and the weld seam cannot be seen or felt. That’s opposed to double submerged arc welding (DSAW), which leaves behind an obvious weld bead that must then be eliminated depending on the application.Welded pipe manufacturing techniques have improved over the years. Perhaps the most important advancement has been the switch to high-frequency electric currents for welding. Prior to the 1970s, low-frequency current was used. Weld seams produced from low-frequency ERW were more prone to corrosion and seam failure.Most welded pipe types require heat treatment after manufacture.Legu pli -

ERW Steel Pipe -Kial vi devus esplori Anisteel por ĉio en SS-pipoj?

Bonvenon al Anisteel, la hejmo de la plej bonaj neoksideblaj ŝtalaj tuboj en la merkato. Ni estas la plej elstara provizanto de la industrio de altkvalitaj neoksideblaj ŝtalaj pipoj kaj akcesoraĵoj. Nia teamo ĝojas prezenti al vi niajn plej bonajn SS-pipproduktojn en gamo da specifoj kaj materialaj gradoj. Ni ebligis la haveblecon de diversaj. gradoj de SS-tuboj kaj tuboj. Ĉi tio inkluzivas neoksideblajn ŝtalojn 304l erw-pipojn kaj neoksideblajn ŝtalojn 321-pipojn. Ni ankaŭ povas provizi SS 304l-tubojn, kaj SS-pipon 304.Ĉi tio faras la elektitajn neoksideblajn tubajn fabrikistojn en Ĉinio por ampleksa aro de komercaj kaj produktadaj bezonoj. Ne kontentiĝi je mezbonaj pipoj, kiuj nur kaŭzos al vi kapdolorojn laŭ la linio. Elektu Anisteel, kaj spertu la diferencon, kiun kvalito kaj servo povas fari. Mendu nun kaj vidu mem kial Anisteel estas la klara elekto por neoksideblaj ŝtalaj tuboj.Legu pli