Tag/as 1163 c350

-

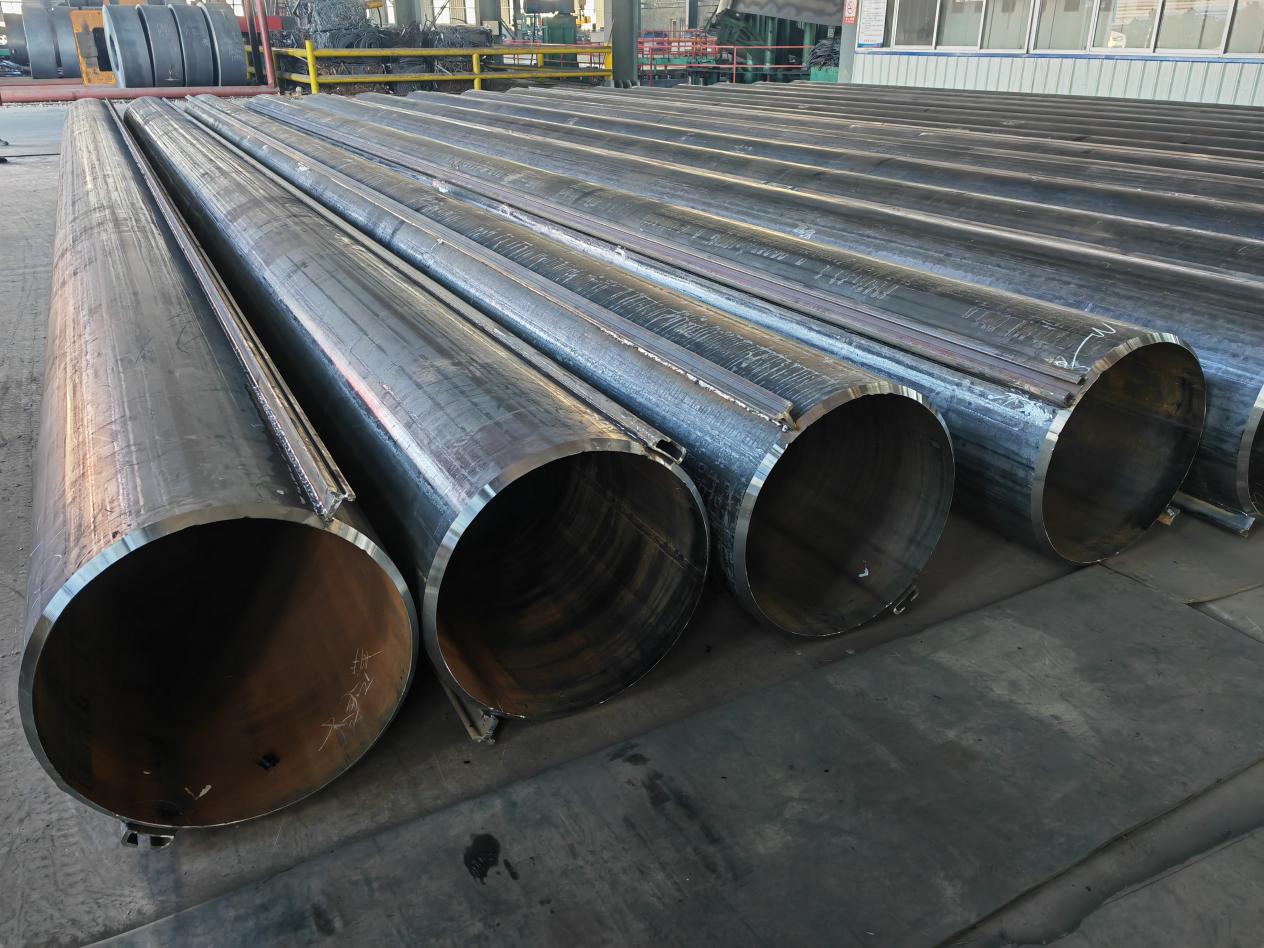

EFW Steel Pipe

EFW Steel Pipe -

High pressure and temperature Alloy Seamless Steel Pipe

High pressure and temperature Alloy Seamless Steel Pipe -

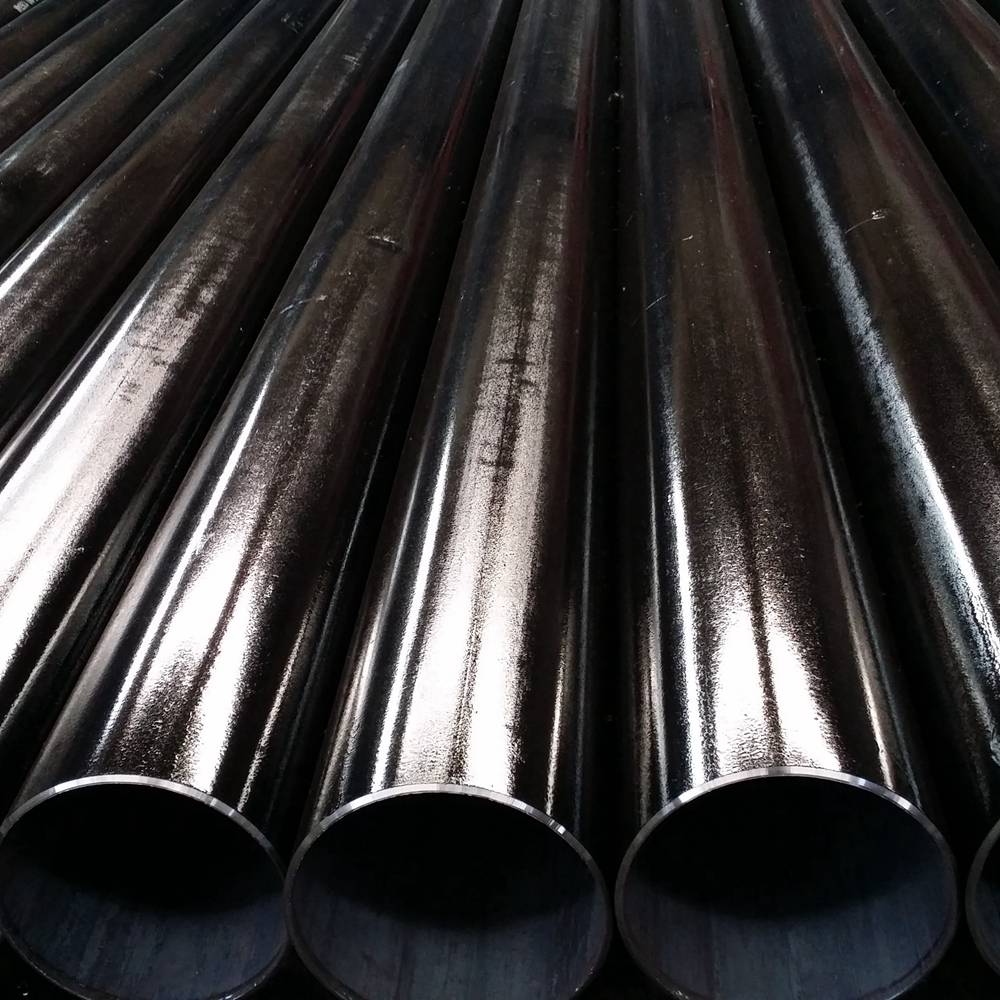

HFW steel pipe

HFW steel pipe -

Carbon Steel Pipes

Carbon Steel Pipes -

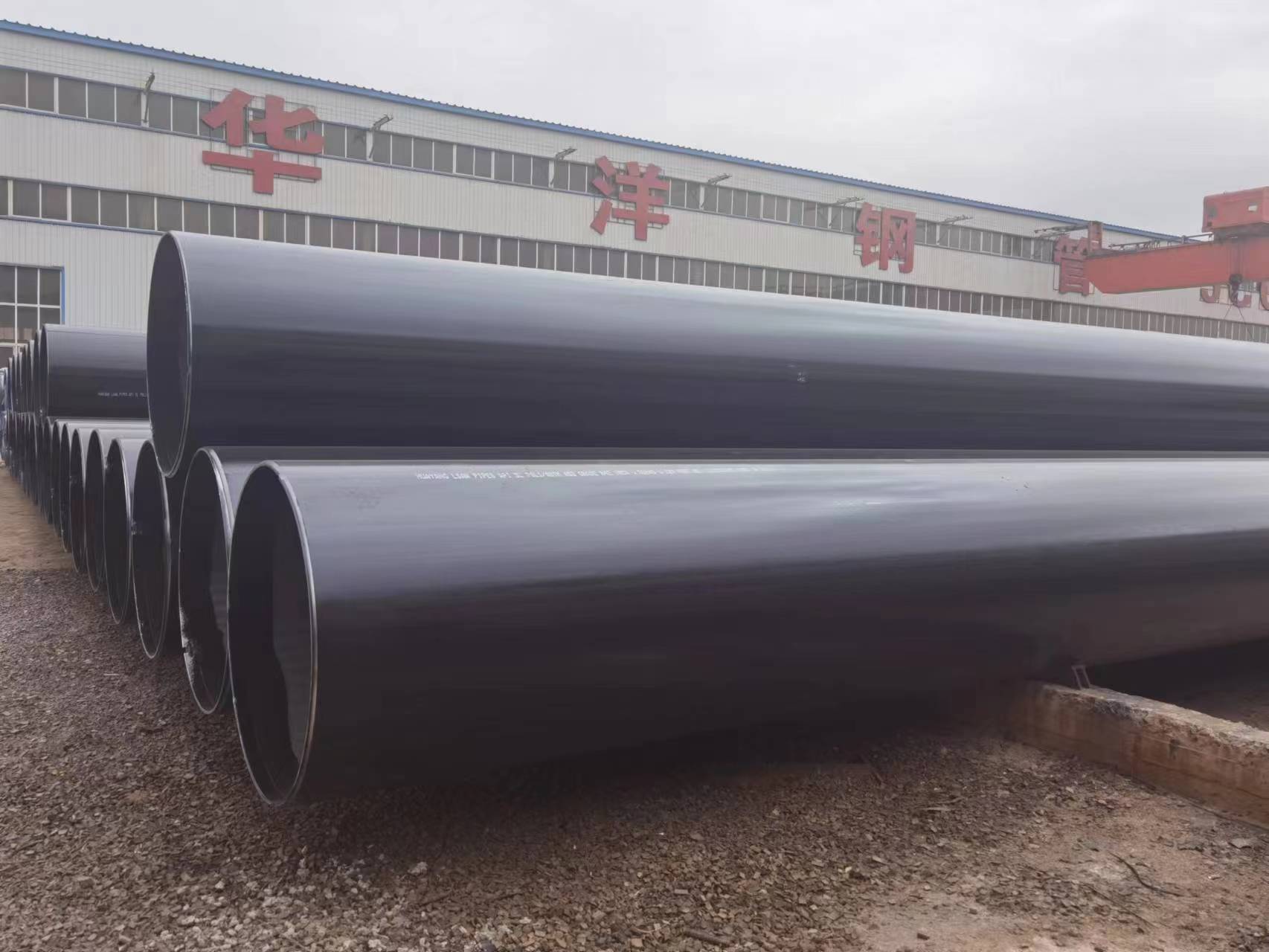

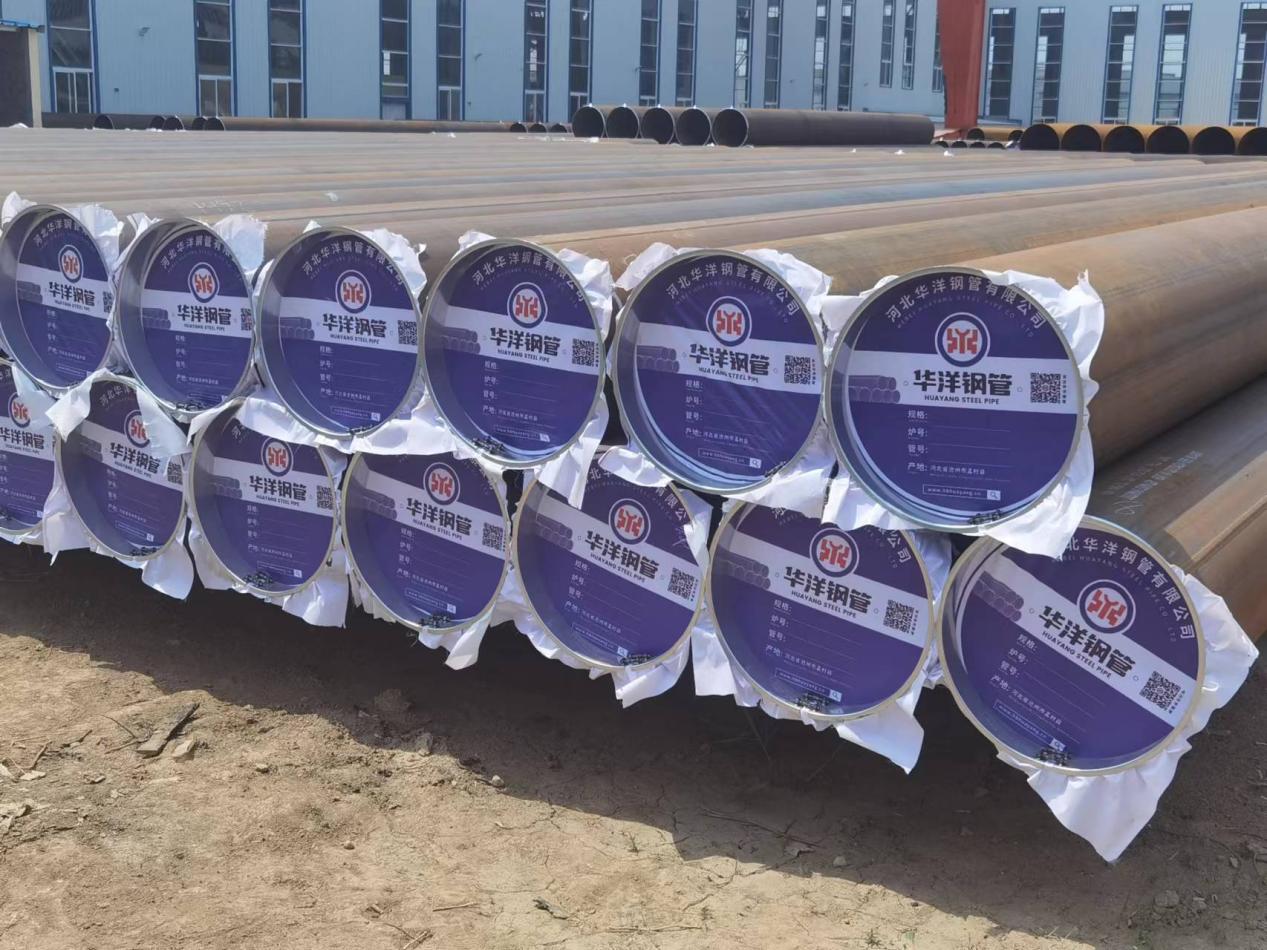

API 5L Pipe Line, Oil & Gas LinePipe, LSAW Steel Pipe

API 5L Pipe Line, Oil & Gas LinePipe, LSAW Steel Pipe -

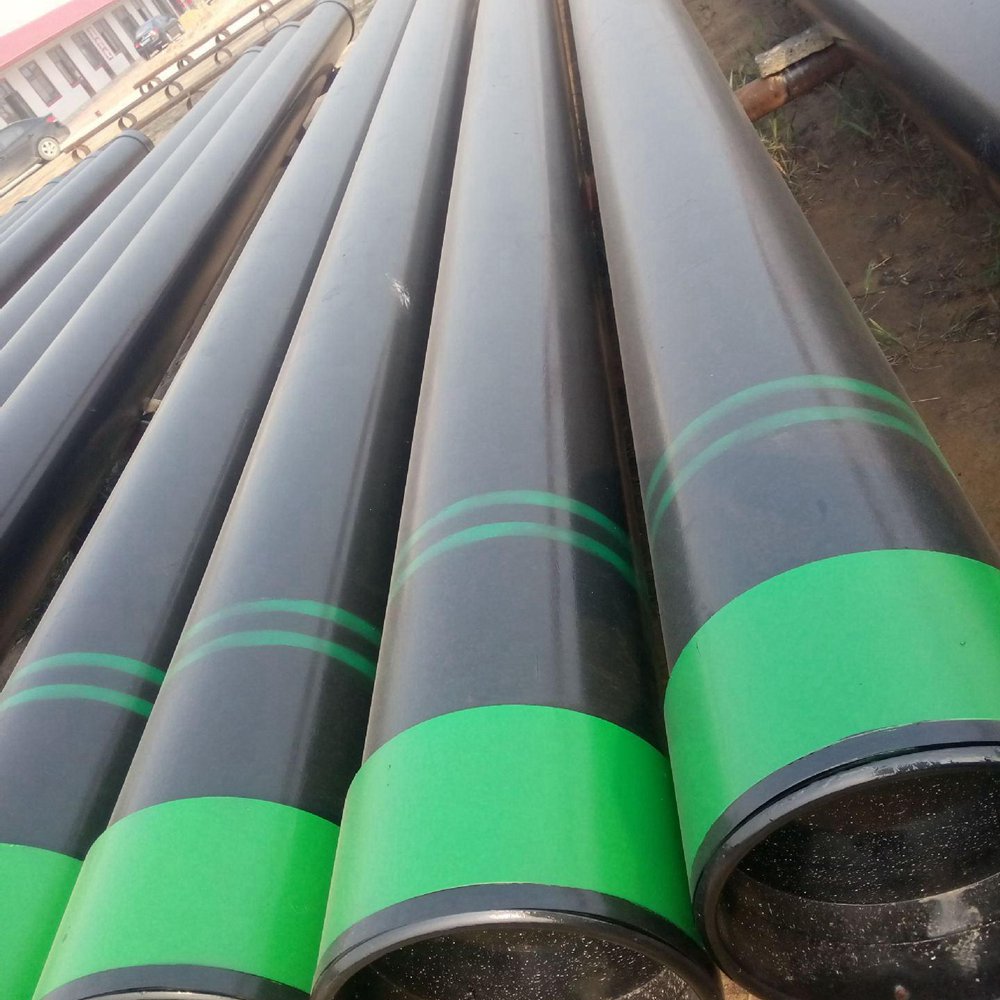

API 5L Black Oil / Gas Line Pipe

API 5L Black Oil / Gas Line Pipe -

API 5L Line Pipe Seamless Steel Pipe

-

ASTM A252 Piling Pipe application in buildings and retaining walls

ASTM A252 Piling Pipe application in buildings and retaining walls -

Welded Steel Pipe

Welded Steel Pipe -

Metal welding services

Metal welding services

Produtct Title

as 1163 c350Related News

-

2024-06-12Suppliers of top-grade 1163 C350, ensuring premium quality.High-Quality 1163 C350 The Benchmark for Suppliers In the realm of industrial materials and compon

-

2024-06-27Wholesale Dealers of 1163 C350 Models for Global Export MarketsThe Dynamic World of Wholesale Exporters A Dive into the Business of Wholesale as 1163 C350 Exporter

-

2024-07-28Top Manufacturers Offering High-Quality 1163 C350 Solutions for Various Industrial ApplicationsHigh Quality Manufacturing Insights from 1163 C350 ManufacturersIn today's competiti

-

2024-06-12Exporting 5L x 42 Steel Pipeline Wholesale API StandardsWholesale API 5L X42 Steel Line Pipe Exporters Key Players in Global Infrastructure DevelopmentIn

-

2024-06-30Top EW Black Round Steel Pipe Exporters Global Market InsightsExploring the Global Market for ERW Black Round Steel Pipes Key Exporters and Their ImpactERW (Ele

-

2024-07-02Top mild steel exporters in China with high quality pipe factories for seamless and efficient production.China is home to many high-quality pipe factories and mild steel exporters, known for their excellen

-

2024-07-29Top Manufacturer of High Quality API Oil Steel Pipes for Durable and Reliable SolutionsHigh-Quality API Oil Steel Pipe ManufacturerIn the ever-evolving world of oil and g

-

2024-11-22Welded Steel Pipe-11 easy tips for cleaning stainless steelClean metal surfaces with these foolproof techniquesLife is full of troubles.Your new stainless steel designer kitchen is a mess of burnt-on grease and fingerprints.A construction company spattered paint and mortar on the elegant steel-clad walls of your building.That cookware that costed you an arm and a leg are stained with coffee and have been ruined by the heat.Your gardener forgot his plain carbon steel pliers on the garden table at your beach house, and rust left a spot on the stainless steel surface.You know, some things happen to everybody at least once.

-

2024-07-22Exporter of High-Quality Dip Galvanized ERW Steel Pipes for Global Markets and Construction NeedsThe Importance of DIP Galvanized ERW Steel Pipe ExportersIn the modern construction

-

2024-07-29Top Suppliers of High-Quality ERW Steel Pipes for Reliable Industrial Applications and DistributionHigh-Quality ERW Steel Pipe Distributor SuppliersIn the dynamic world of manufactur

-

2024-07-27Innovative Solutions from Leading Hollow Section Manufacturers for Structural and Engineering ApplicationsHollow Section Manufacturers A Key Player in Modern ConstructionIn the world of con

-

2024-07-31Wholesale Suppliers of ERW Steel Pipes Complying with ASTM A53A Standards and SpecificationsUnderstanding Wholesale ERW Steel Pipes A Focus on ASTM A53A FactoriesIn the world

-

2024-06-24Top ERW Steel Pipe Wholesale Exporters Global Trade InsightsWholesale ERW Steel Pipe Exporters Key Players in Global Trade ERW (Electric Resistance Welded) st

-

2024-06-12Chinese manufacturers of galvanized ERW steel pipes for exportChina's Dip Galvanized ERW Steel Pipe Manufacturing Factories A Global Force in Industrial Excellenc

-

2024-11-22Introduction of LSAW Steel Pipe-lsaw steel pipe-erw pipeLongitudinally Submerged Arc Welded Process FlowLSAW (Longitudinally Submerged Arc Welded Steel pipes) in leaflets plate as raw material, the steel plate in the mold or molding machine pressure (volume) into using double-sided submerged arc welding and flaring from production.The LSAW process of welded tube includes UOE and JCOEUOE LSAW pipe forming process:The three main forming processes of UOE LSAW steel pipe forming process include: steel plate pre-bending, U forming and O forming. Each process adopts a dedicated forming press to complete the three processes of pre-bending the edge of the steel plate, U forming and O forming in sequence to deform the steel plate into a circular tube.

-

2024-11-22Stainless Steel EFW Pipe-YOUR EVERY DAY METAL: HOW IT'S MADEIf you look around, you will see a lot of steel. Next to plastic and paper, it’s one of the most common materials in products used every day. From your car to your kitchen stove to the door locks, steel is everywhere. In fact, to really put into perspective how essential steel is to our modern world, think about this - it takes steel to make steel.

-

2024-06-20API 5L X52 steel pipes from ChinaUnderstanding China API 5L X52 Steel Pipe A Comprehensive OverviewChina API 5L X52 steel pipe is a

-

2024-06-23High Quality API 5L PSL1 ExportersHigh-Quality API 5L PSL1 Exporters Ensuring Efficiency and ReliabilityIn the realm of construction

-

2024-11-22Stainless steel-The Simple (and right) Way to Clean Stainless Steel AppliancesI love hand prints and fingerprints! I love seeing my four little ones’ hands and fingers at different stages of their growth. Seeing how tiny they once were is such fun! We do lots of art projects with our hands, giving me ample opportunity to soak up the memories and keep them forever.BUT, what I don’t love is the fingerprints and hand prints I keep finding on various hard surfaces in our home. I have wiped down walls, doors, windows, etc. Really I didn’t have a problem with cleaning them up. But before we were parents, we purchased all stainless steel appliances for our kitchen. I say before we were parents because we might have thought twice after, even though we love the look of stainless steel. The only problem is keeping them clean! Keeping them clean after kids is even more of a problem! A general wipe down just won’t do with stainless.

-

2024-07-30Top wholesale 5l-b carbon steel pipe manufacturers for API projects and more.Carbon steel pipes are essential components in various industries, ranging from construction to oil

Related Search

- as 1163 c350

- high quality as 1163 c350

- china as 1163 c350

- wholesale as 1163 c350

- as 1163 c350 exporter

- as 1163 c350 factory

- as 1163 c350 factories

- as 1163 c350 manufacturers

- as 1163 c350 supplier

- as 1163 c350 manufacturer

- as 1163 c350 exporters

- as 1163 c350 suppliers

- wholesale as 1163 c350 factory

- wholesale as 1163 c350 manufacturer

- wholesale as 1163 c350 factories

- wholesale as 1163 c350 exporters

- wholesale as 1163 c350 supplier

- wholesale as 1163 c350 manufacturers

- wholesale as 1163 c350 suppliers

- wholesale as 1163 c350 exporter

- china as 1163 c350 factory

- china as 1163 c350 manufacturer

- china as 1163 c350 factories

- china as 1163 c350 exporters

- china as 1163 c350 supplier

- china as 1163 c350 manufacturers

- china as 1163 c350 suppliers

- china as 1163 c350 exporter

- high quality as 1163 c350 factory

- high quality as 1163 c350 manufacturer